Mould processing clamp

A mold processing and fixture technology, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problem of low processing accuracy and achieve the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

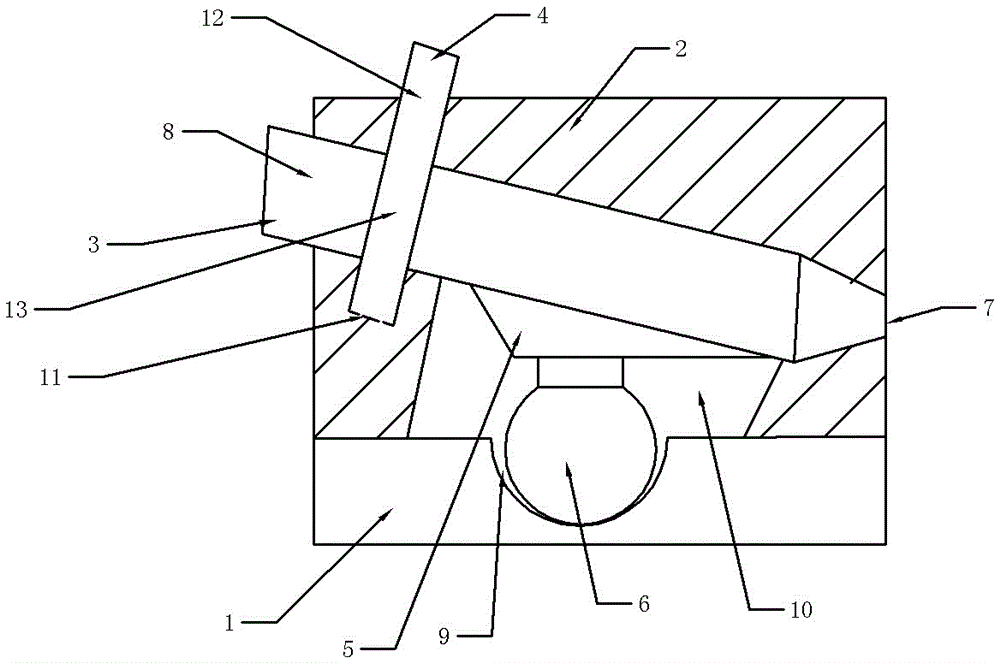

[0010] The reference signs in the drawings of the description include: base 1, clamp body 2, clamping shaft 3, positioning pin 4, fastening block 5, workpiece 6, first mounting hole 7, second mounting hole 8, first concave Groove 9, second groove 10.

[0011] A mold processing fixture, comprising a base 1 and a clamp body 2, the base 1 and the clamp body 2 are fixedly connected, the base is provided with a first groove 9, and the inner wall of the first groove 9 is an arc surface, increasing The contact area between the spherical surface of the workpiece 6 and the first groove 9, the chuck body is provided with a second groove 10, and the first groove 9 and the second groove 10 constitute a cavity for placing the workpiece 6, and the chuck body 2 is provided with a first groove 10. Mounting hole 7, second mounting hole 8, clamp body 2 is provided with clamping shaft 3, clamping shaft 3 passes through the second mounting hole 7 and is against the bottom of the first mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com