Self-clamping linkage clamp capable of preventing shaft rotation

A linkage and clamping technology, applied in the direction of wrenches, wrenches, manufacturing tools, etc., can solve problems such as falling off, oil leakage of internal connecting lines, and rotation of lead shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

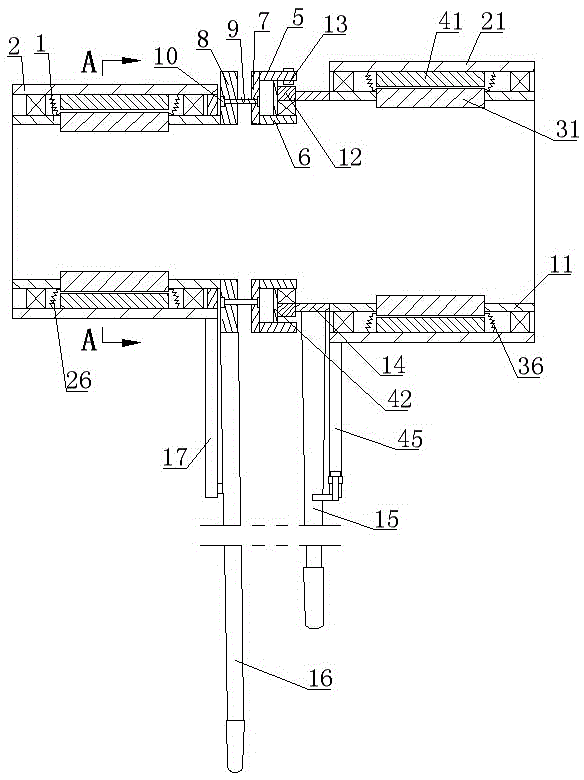

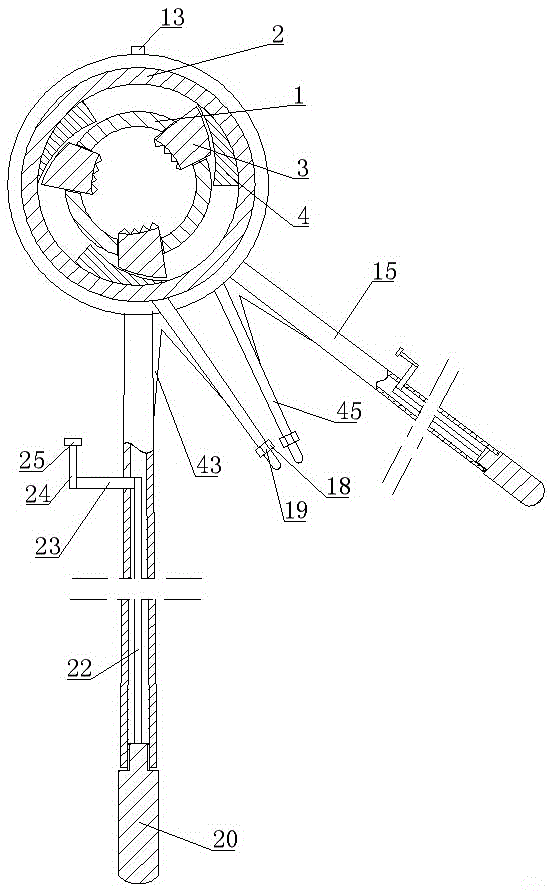

[0015] Such as figure 1 with figure 2 As shown, the anti-rotational self-clamping linkage pliers include a front clamping mechanism for clamping the shaft, a rear clamping mechanism for clamping a fixing member screwed on the shaft, and the front clamping mechanism and the rear clamping mechanism There is a connecting mechanism connecting the two and enabling them to perform one-way relative rotation. The connecting mechanism can extend axially, and its maximum extending distance is greater than the axial length of the fixing piece.

[0016] The front clamping mechanism in the present invention includes a front clamping inner tube 1 and a front clamping outer tube 2 which are nested together and can rotate relatively. Between the front clamping inner tube 1 and the front clamping outer tube 2, there is a The rotation connection between the two is realized by installing bearings. The middle ring of the front clamping inner cylinder 1 is equipped with three front clamping bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com