An abrasive belt cylinder cutting structure

A kind of abrasive belt cylinder and sawing technology, which is applied in metal processing and other directions, can solve the problems of poor quality, low efficiency, and low production capacity, and achieve the effects of short cutting time, avoiding random jumping, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

[0030] Glossary

[0031] Abrasive belt cylinder, referred to as cylinder, refers to a bundle of tubular abrasive belts bonded by a large number of abrasive belts, and its cross section is circular.

[0032] Abrasive belt cylinder cutting machine refers to a machine that cuts a long abrasive belt cylinder into short abrasive belt cylinders in the automatic production of thousand-page wheels.

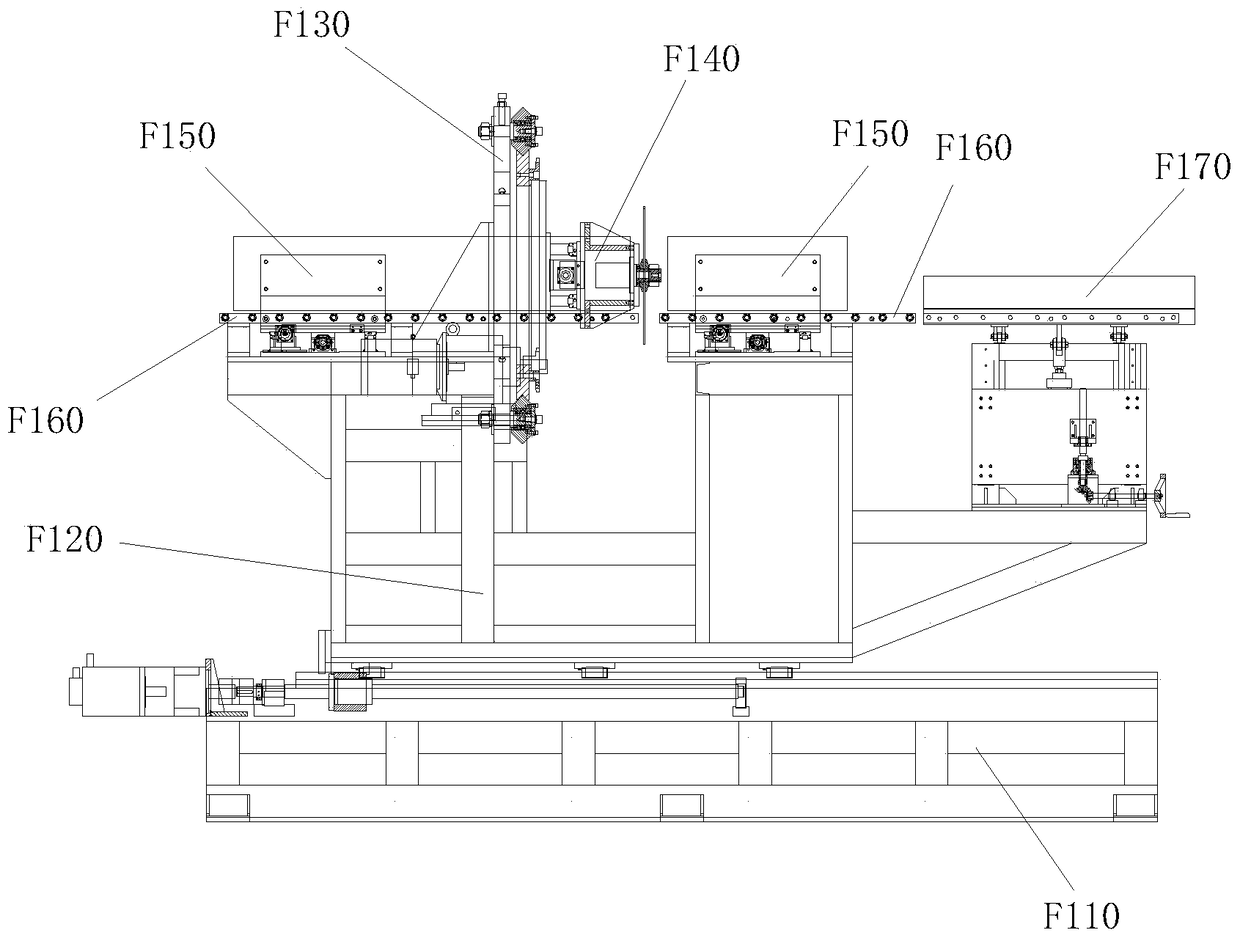

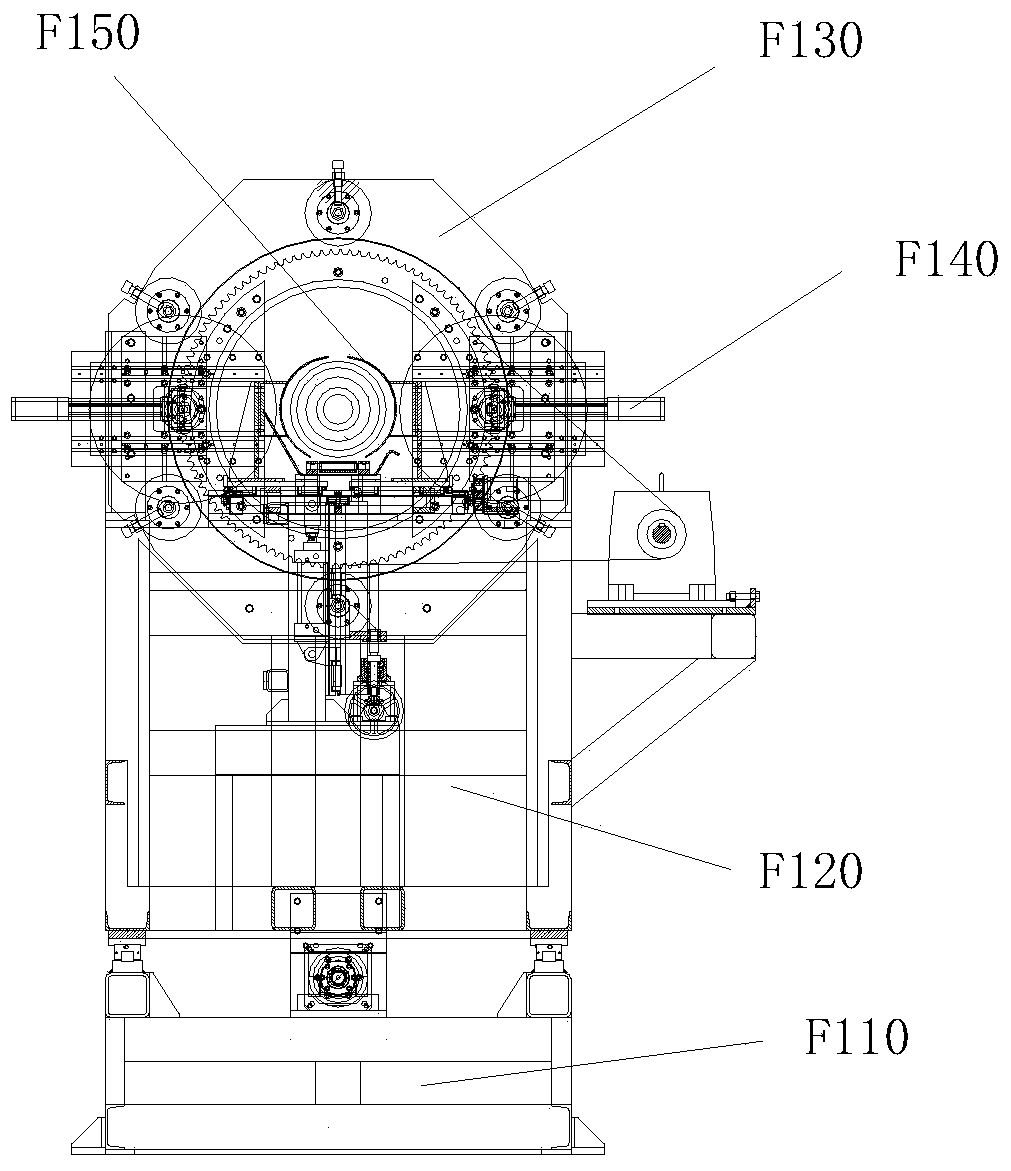

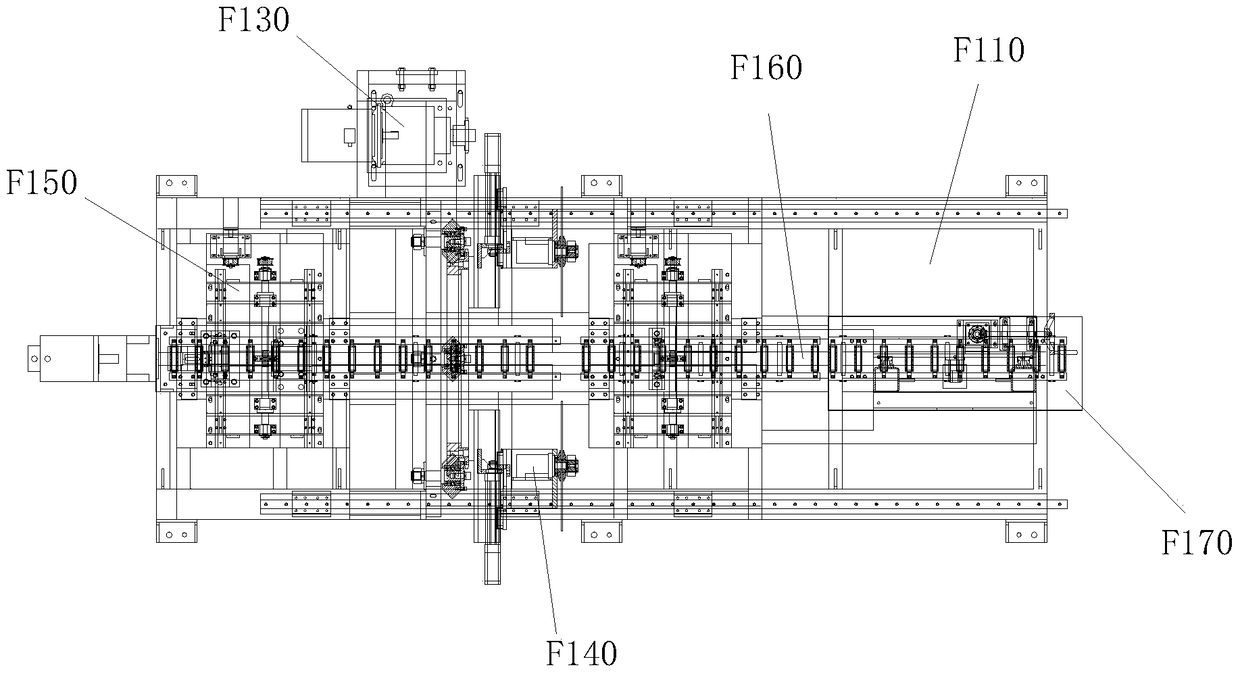

[0033] Such as figure 1 , figure 2 and image 3 As shown, the invention discloses a cutting structure for abrasive belt cylinders, which cuts a long abrasive belt cylinder into sections of short abrasive belt cylinders with the same length through reciprocating motion. Wherein, the cutting structure includes a sliding rail frame F110, a frame F120, a tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com