A coding mechanism and coding method for a triangular plastic cup

A technology of plastic cups and triangles, applied in typewriters, printing devices, printing, etc., can solve the problems of low coding efficiency and high labor costs, and achieve the effect of improving coding efficiency, reducing production and labor costs, and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

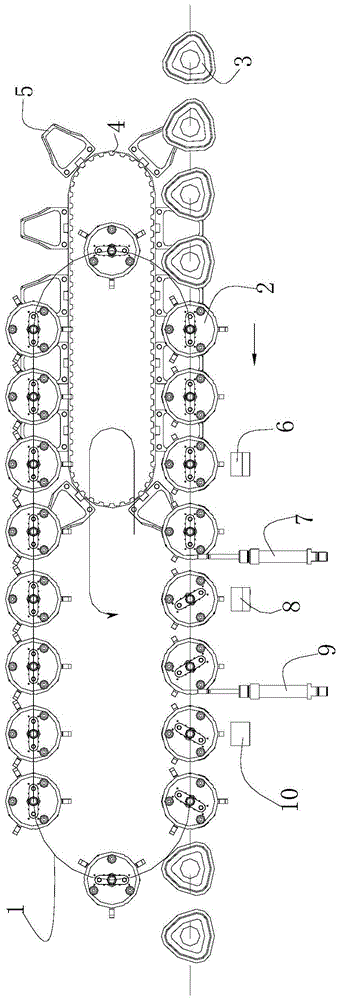

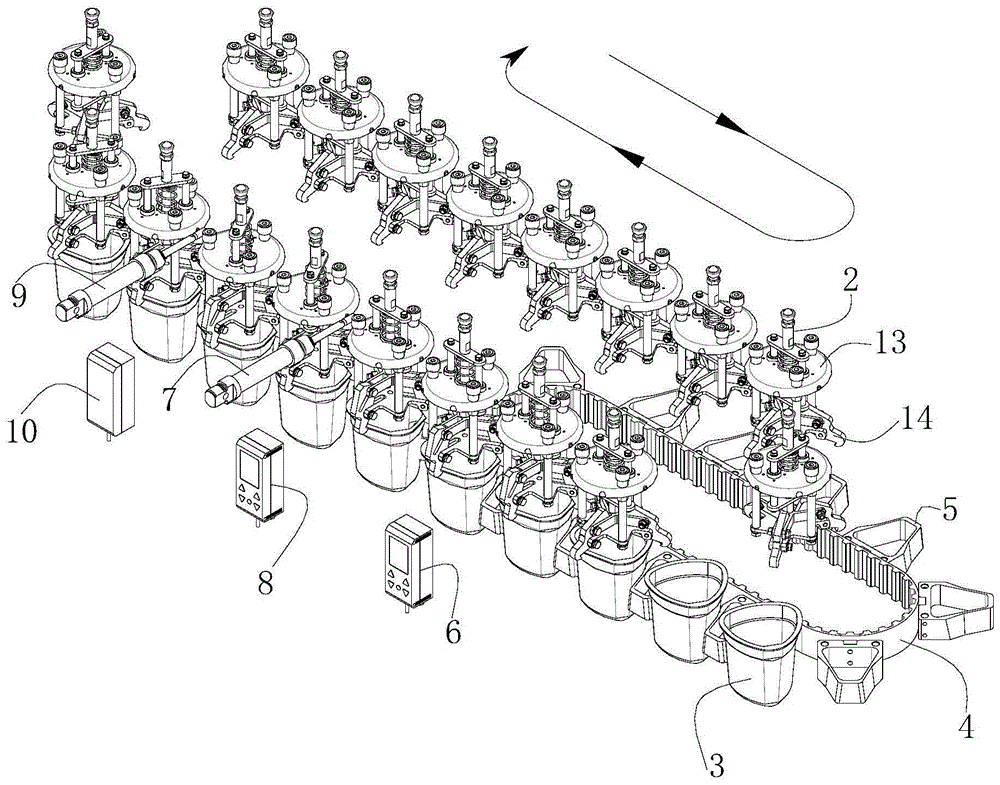

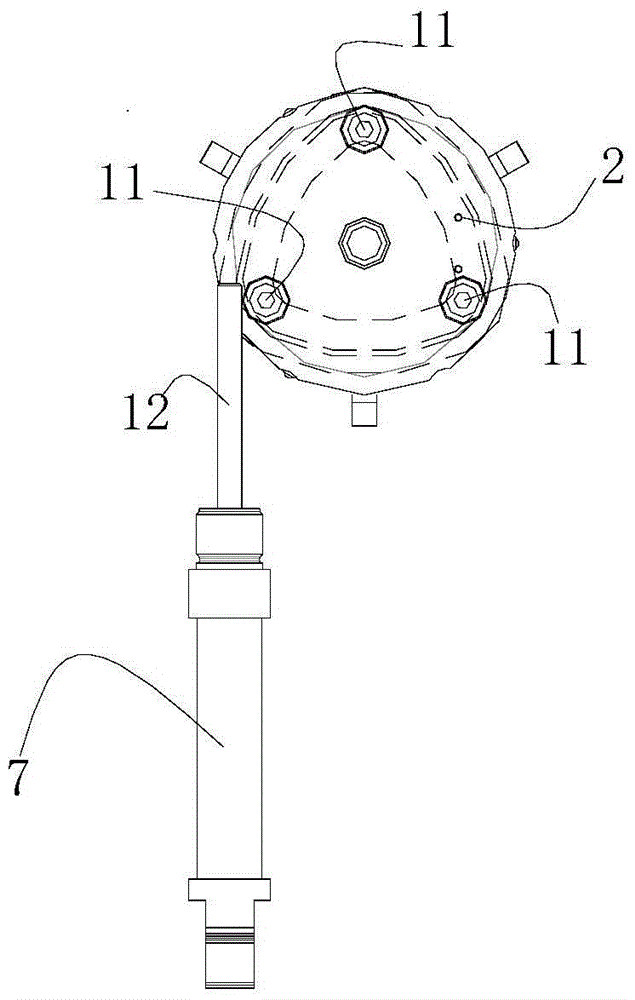

[0027] Such as Figure 1-2 As shown, a coding mechanism for a triangular plastic cup is provided with different marks on the three outer surfaces of each triangular plastic cup 3, including a conveying line, a frame, a plurality of jaw assemblies 2, a first view Like the electric eye 6, the second video electric eye 8, the first cylinder 7, the second cylinder 9 and the inkjet gun 10, part of the jaw assembly 2 is located above the conveying line, and an annular track groove 1 is arranged on the frame. The claw assemblies 2 are all arranged on the annular track groove 1, and the first video electric eye 6, the second video electric eye 8 and the inkjet gun 10 are sequentially arranged along the conveying direction of the conveying line and are all located above the place where the claw assembly 2 is provided. On the same side of the conveying line, the first air cylinder 7 is located above the position between the first video electric eye 6 and the second video electric eye 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com