Intelligent assembling workbench for independent suspension assembly of electric vehicle

A technology of assembling workbench and independent suspension, applied in the direction of wheel assembly and disassembly equipment, wheel and tire installation, etc., can solve the problems of high labor intensity and inconvenient docking, reduce labor intensity, easy to operate, convenient for quick docking and assembling and fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

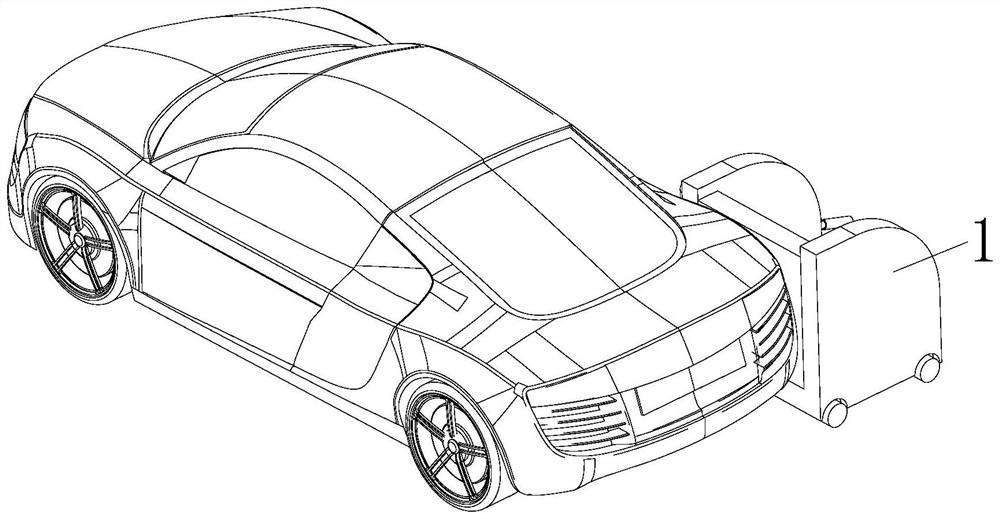

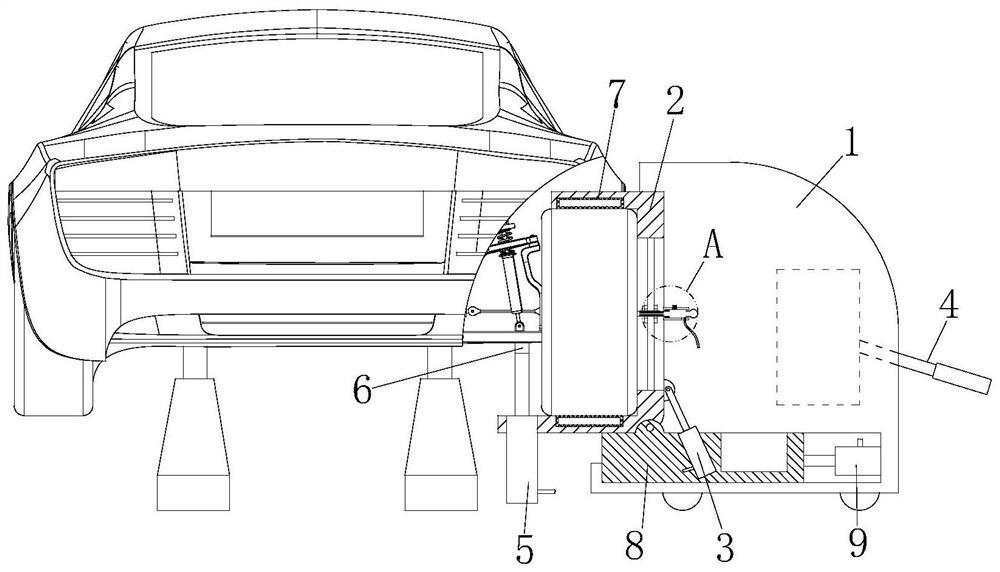

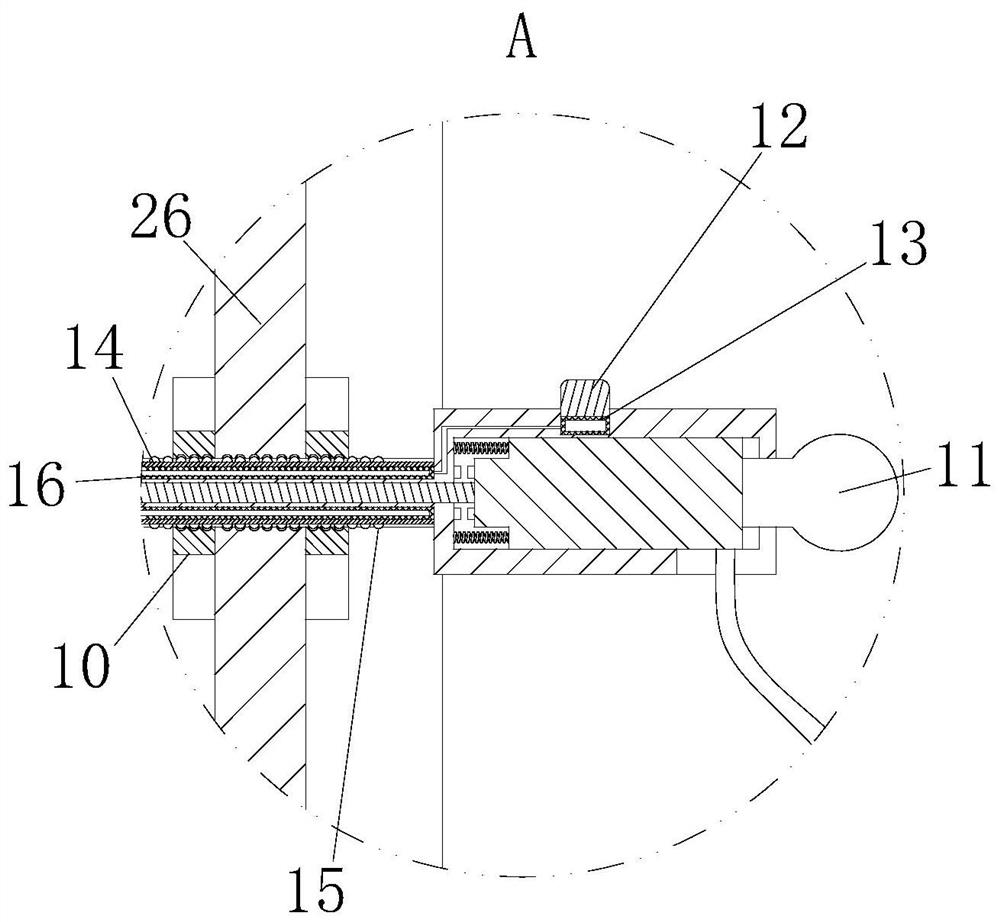

[0030] see Figure 1-5 As shown, an intelligent assembly workbench for an independent suspension assembly of an electric vehicle includes a moving seat 1, a rotating plate 2 and a push rod 3, and the top of the moving seat 1 is provided with a rotating groove; the inner rotating connection of the rotating groove There is a rotating plate 2; the surface of the rotating plate 2 is provided with a fixed groove, and the inside of the fixed groove is provided with a wheel; the groove bottom of the fixed groove is provided with a through hole; between the rotating plate 2 and the groove bottom of the rotating groove A jack 3 is provided; a jack 4 is fixedly connected to the side of the moving seat 1, and the jack 4 and the jack 3 are connected to each other through a connecting pipe; during work, with the popularization of cars, the demand for car maintenance is increasing , the car wheel is a part with a high frequency of car maintenance. After a long time of use, the car wheel wil...

Embodiment 2

[0040] see Image 6 As shown, the head of the electric wrench 11 is provided with a moving block; the inside of the electric wrench 11 is fixedly connected with an electric motor 22; the surface of the moving block is provided with a transmission groove; the bottom of the transmission groove is fixedly connected with a The third airbag 23; the counterweight 20 offers a limiting groove relative to the side of the changing post 17; the inside of the limiting groove is slidingly connected to the limiting plate 24; the bottom of the limiting groove is fixedly connected with The fourth airbag 25, and the fourth airbag 25 and the third airbag 23 are connected to each other; when working, by setting the moving block, when the socket head 18 of the electric wrench 11 is squeezed by manpower, the socket head 18 will drive the movement The block moves, so that the output shaft of the moving block and the electric motor 22 is connected to each other, and then the electric motor 22 can dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com