Clamping jaw mechanism

A jaw and cylinder technology, applied in the field of product packaging, can solve the problems of low packaging production efficiency, high placement production cost, labor resource occupation, etc., and achieve the effect of easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

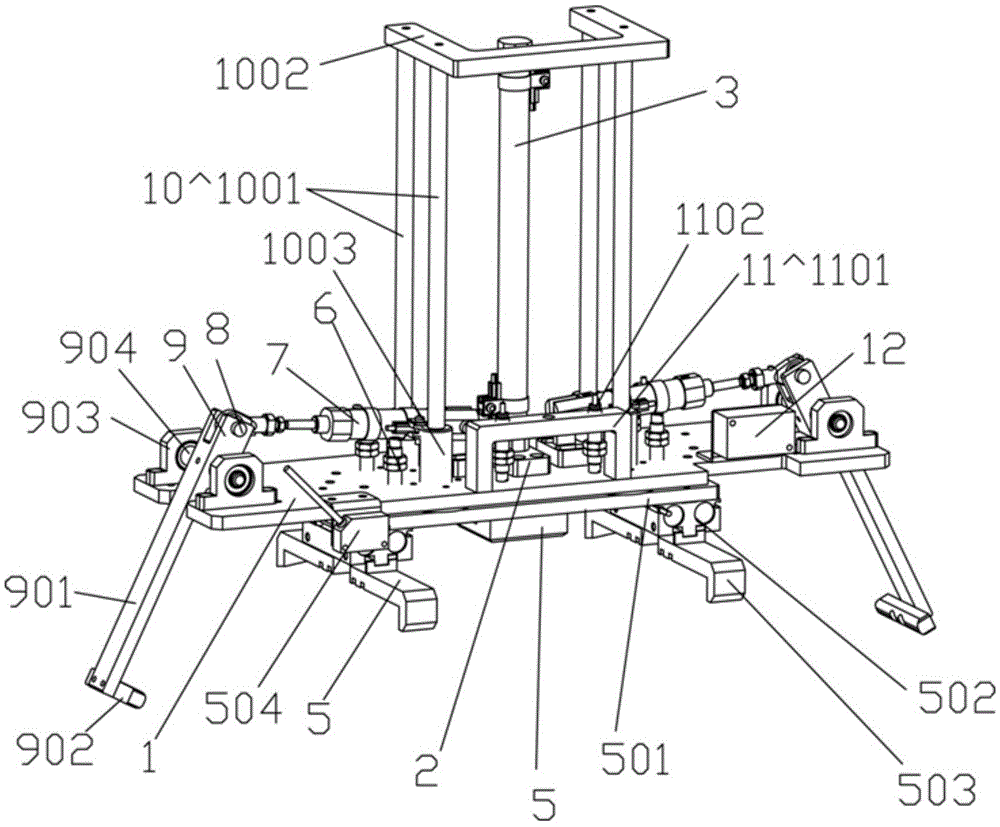

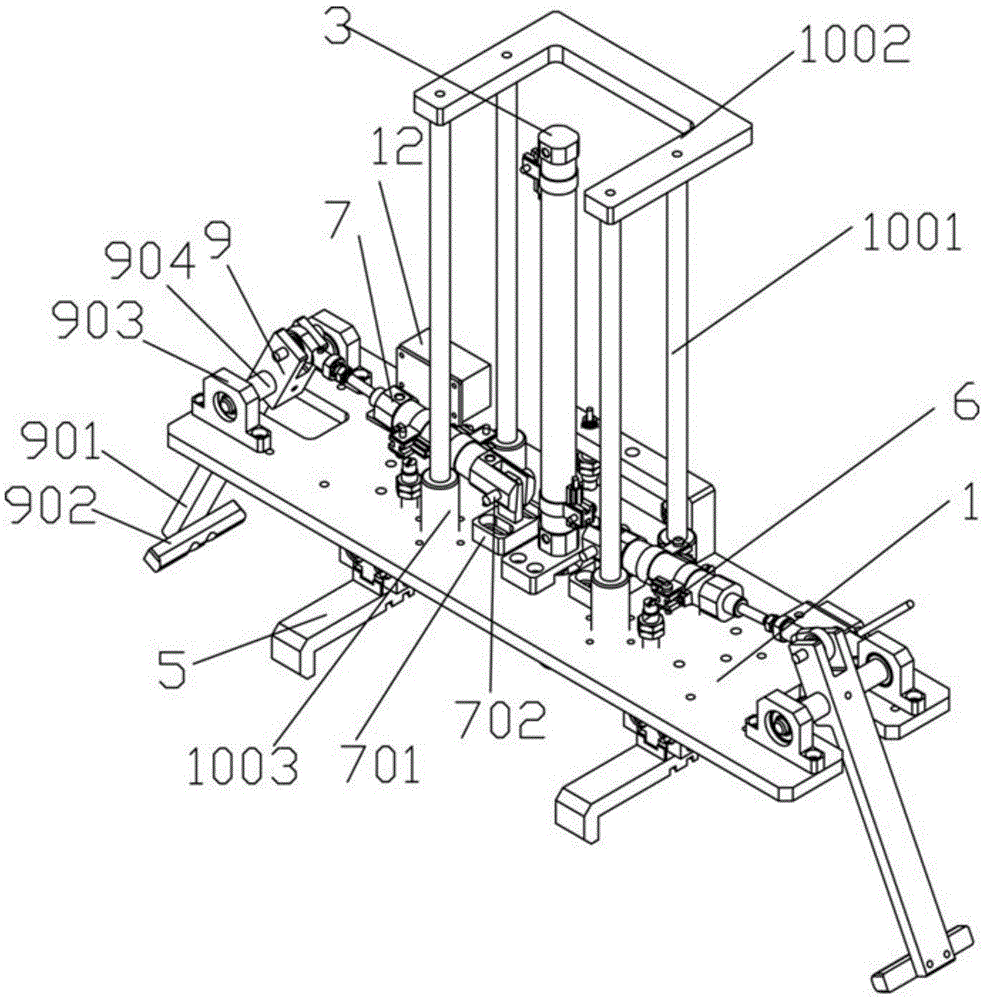

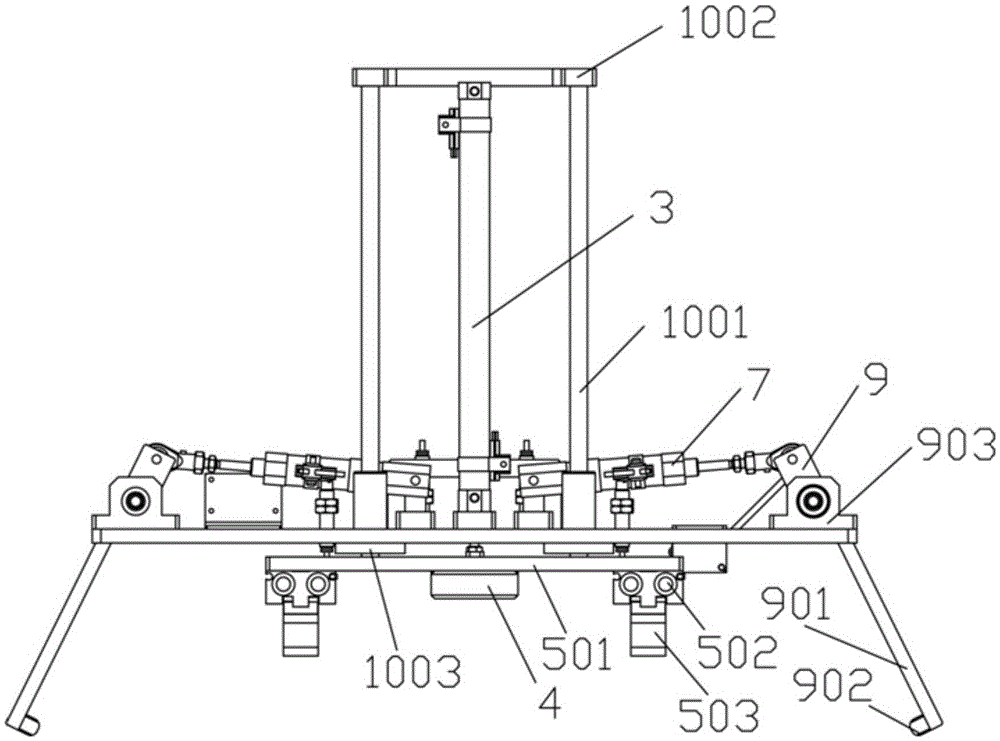

[0056] refer to Figure 1-Figure 3 , this embodiment provides a gripper mechanism, including a device board 1, a jacking cylinder module arranged at the upper end of the device board 1, a gripper module 5 arranged at the lower end of the device board 1, and respectively arranged on the left and right sides of the jacking cylinder module The folding cylinder module 7 on the device board 1, and the platen module 9 arranged on the device board 1 and used in conjunction with the folding cylinder module 7;

[0057] The jacking cylinder module includes a jacking cylinder fixing block 2 fixedly arranged on the device plate 1, a jacking cylinder 3 fixedly arranged on the jacking cylinder fixing block 2 and used in conjunction with the jaw module 5;

[0058] The jaw module 5 includes a jaw mounting plate 501 fixedly connected to the cylinder shaft of the jacking cylinder 3 through the jacking cylinder connecting block 4, a jaw cylinder 502 disposed on the jaw mounting plate 501, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com