Method for reducing annealing defect of aluminum product

An annealing and defect technology, applied in the field of aluminum production and processing, can solve the problems of insufficient coiling tension, low coiling tension, and sticking of the outer ring of aluminum coils, so as to solve the annealing sticking defect and prevent the problem of loose layers. , the effect of reducing annealing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

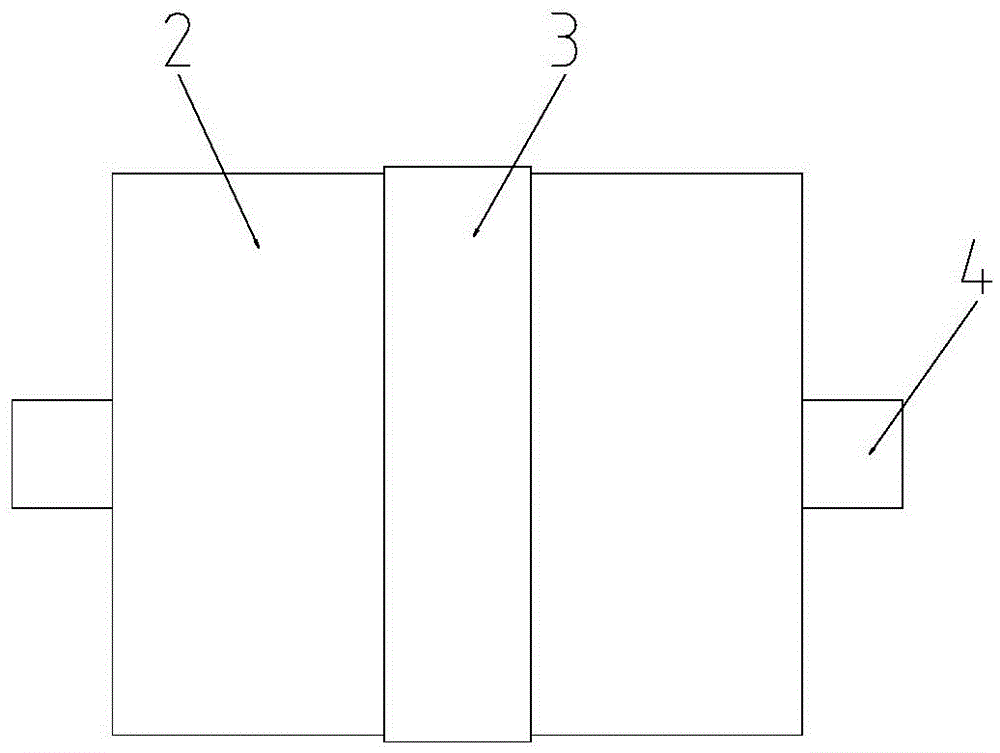

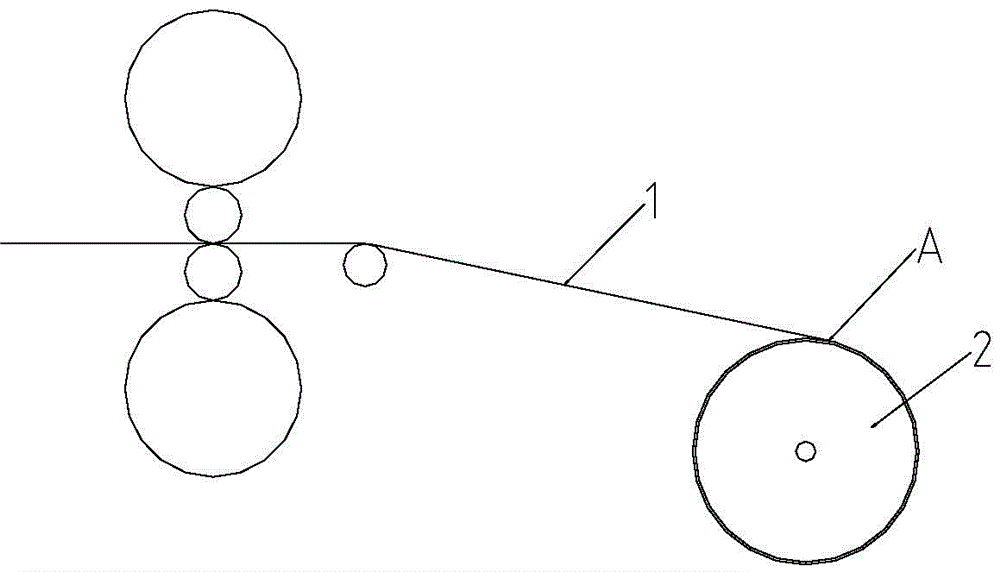

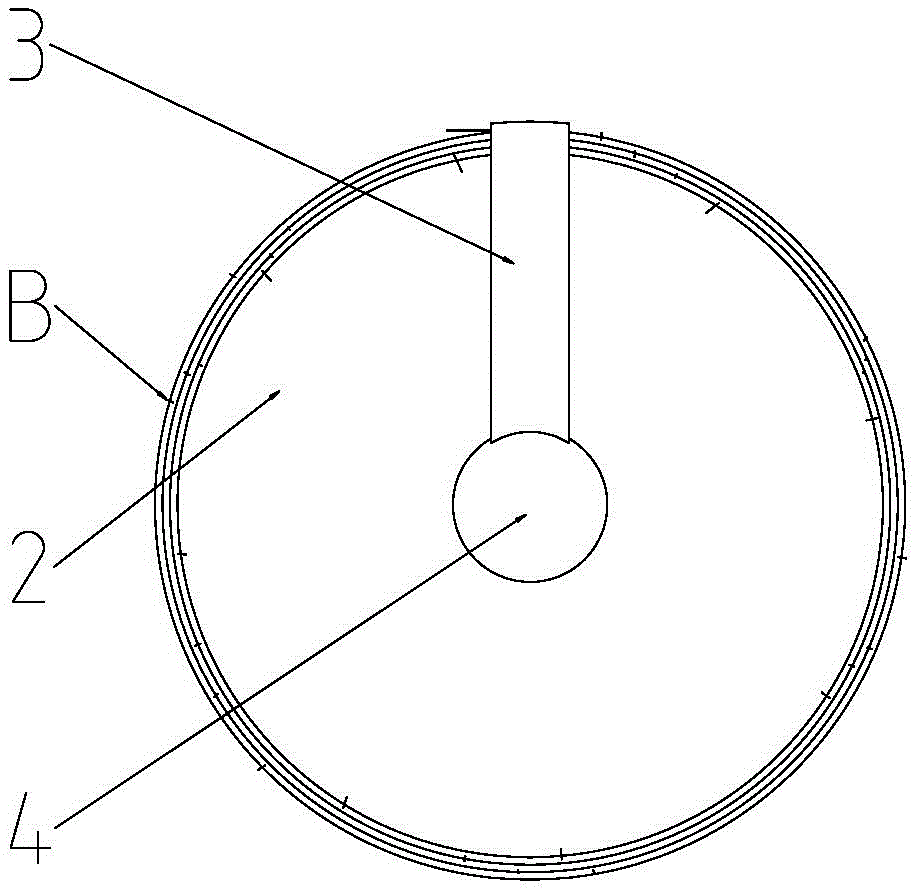

[0020] The method for reducing the annealing defect of the aluminum material in this embodiment is that in the process of pulling and leveling the aluminum strip, after the tail is stripped off, at the coiling place of the aluminum strip 1, the aluminum strip 1 and the aluminum coil of the outermost ring of the aluminum coil are combined. The two ends of the strip are welded and fixed until all the aluminum strips 1 are coiled, and the welded part A is as figure 2 As shown, each spot welding position B is as image 3 shown. After the aluminum strip 1 is stretched, straightened, cleaned and coiled, the outer ring of the aluminum coil 2 is fixed before entering the finished anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com