Plug connector and fluid connector assembly using the plug connector

A plug connector, plug housing technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of affecting the use effect of the connector, twisting and deformation of the valve core spring, and inability to ensure sealing, etc. To achieve the effect of convenient plugging, reducing plugging resistance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

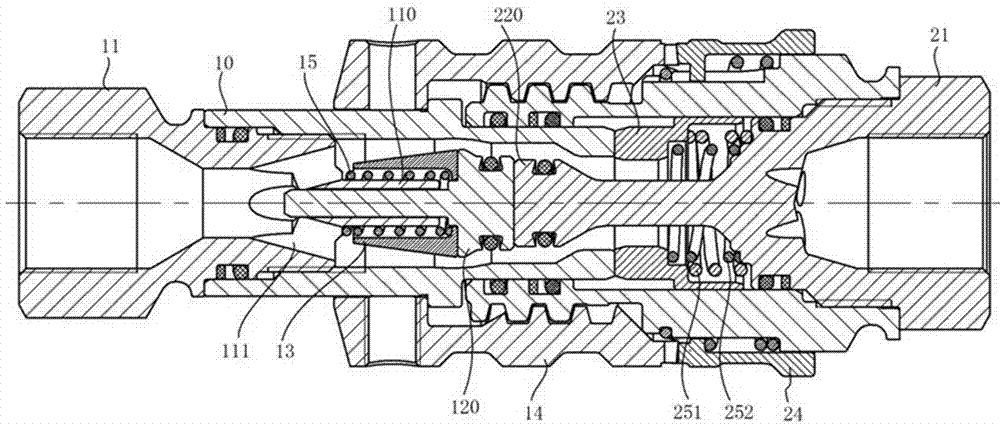

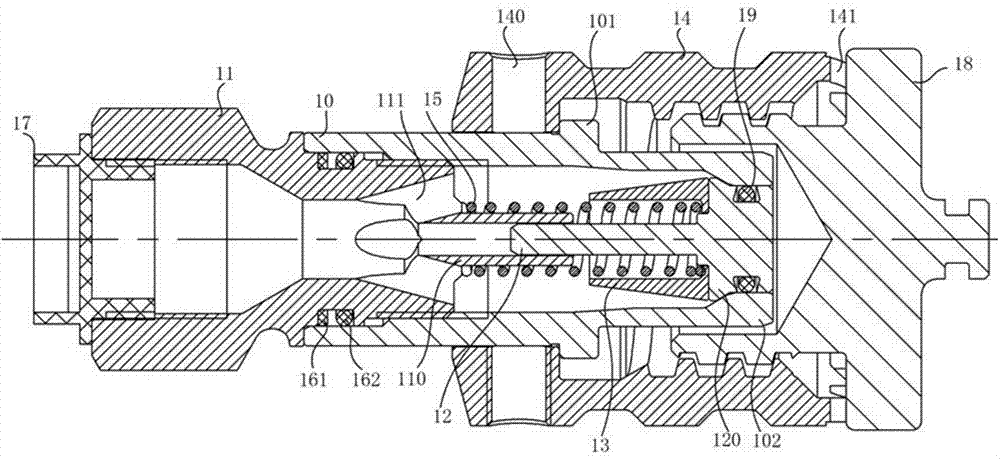

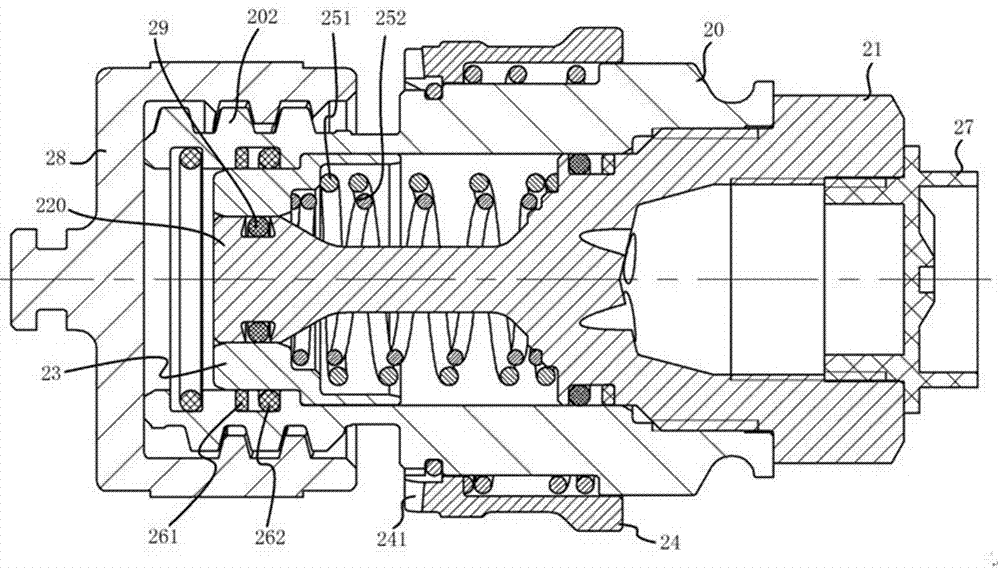

[0022] Embodiment 1 of the fluid connector assembly of the present invention: as figure 1 shown, including plug and socket connectors. Among them, the structure of the plug connector is as follows figure 2 As shown, the plug housing is included. For the convenience of description, the front end of the plug housing is defined as the plug end.

[0023] In this embodiment, the plug housing includes a front housing 10 and a rear housing 11, the front and rear housings are connected by threads, and the front housing 10 is equipped with a plug spool 12 for guiding and moving in the front and rear directions, and the plug spool 12 includes a front end The spool head 120 and the rear end of the spool, the outer diameter of the spool head 120 is greater than the outer diameter of the rear end, the rear end of the plug spool 12 is sleeved with a plug spring 15, and the rear housing 11 is provided with a The spring seat at the rear end of the fixed plug spring 15 is fixed, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com