A sealing method for cracked rock mass resistant to high seepage pressure under shearing action

A fractured rock mass and high permeability resistance technology, applied in the direction of applying stable tension/pressure to test material strength, permeability/surface area analysis, measuring devices, etc., can solve problems that cannot reflect the mechanical properties of fractured rock mass, and achieve measurement Convenient steps, accurate and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sealing method for a fractured rock mass resistant to high osmotic pressure under shearing in this embodiment comprises the following steps:

[0027] Step 1. Device Layout

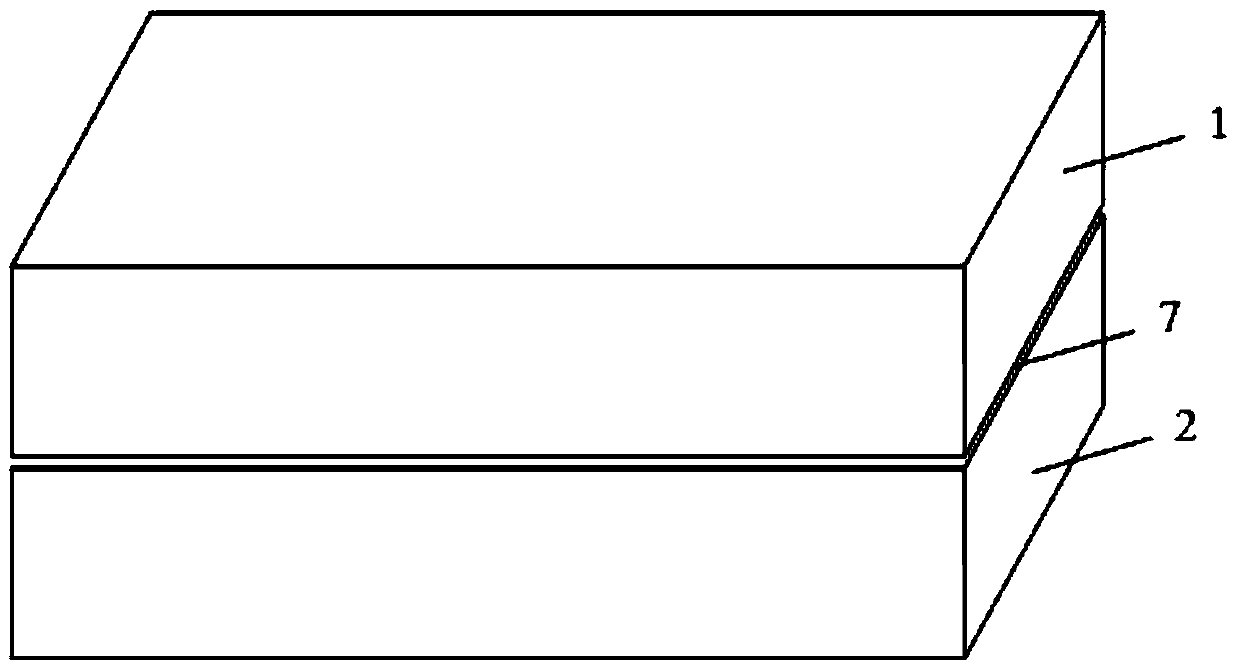

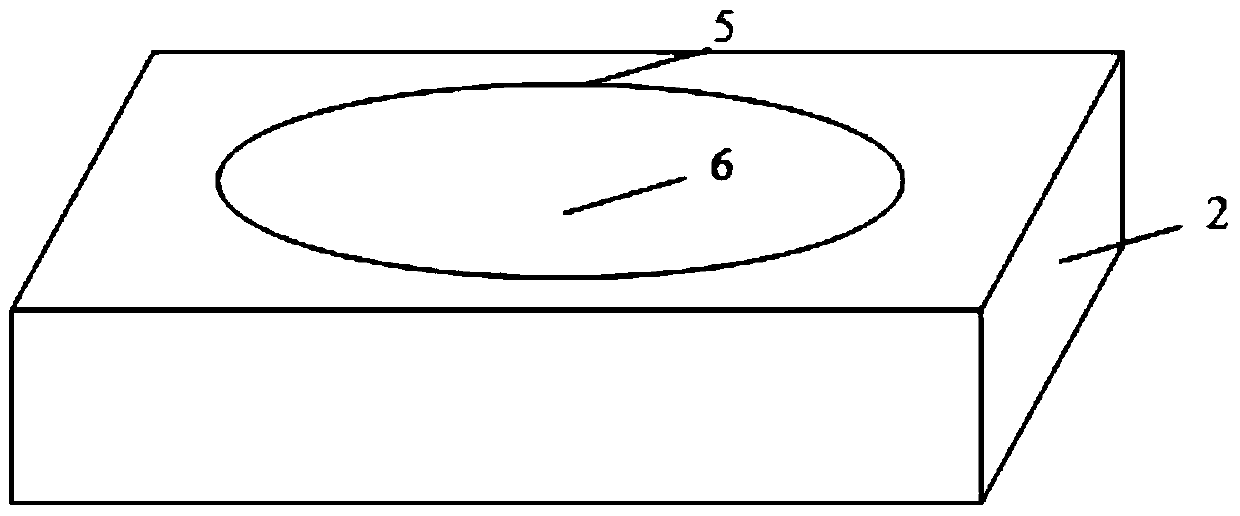

[0028] Such as figure 1 As shown, two rock masses of the same material are stacked up and down, and the lower surface of the upper fractured rock mass 1 and the upper surface of the lower fractured rock mass 2 form a contact surface 7; the upper surface of the lower fractured rock mass 2 is provided with a circle of concave Groove, the seal ring 5 is placed in the groove; several through holes 3 are drilled up and down inside the upper fractured rock mass 1, and the lower end faces 4 of the through holes 3 are included in the area surrounded by the seal ring 5 of the lower cracked rock mass 2 .

[0029] Step 2. High osmotic pressure resistant seal under shear action

[0030] Water flows in from part of the through hole 3 of the upper fractured rock mass 1, seeps inside the sealing ring 5 of the...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is:

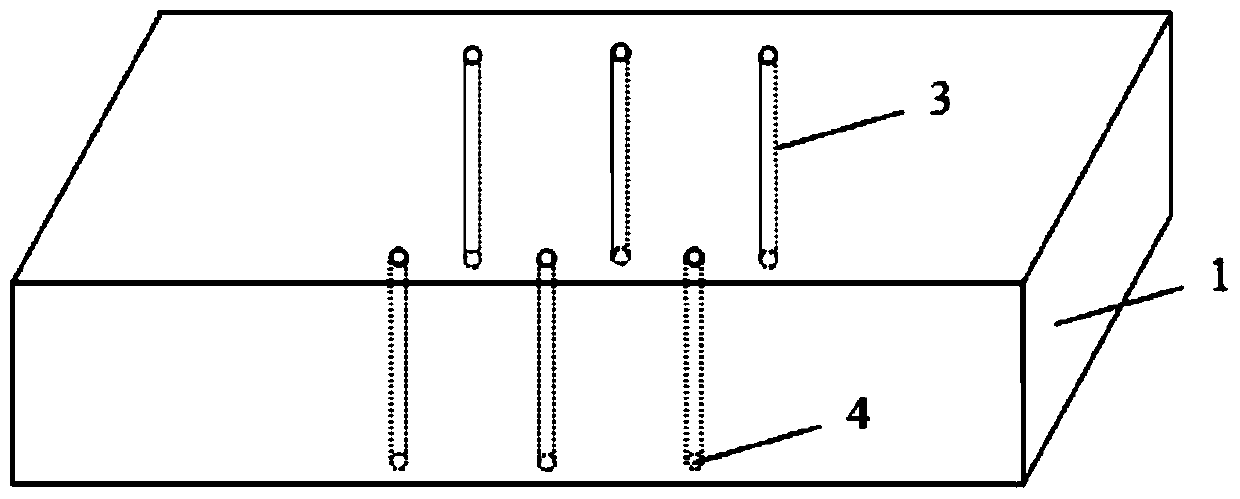

[0034] Such as figure 2 As shown, the through holes 3 of the upper fractured rock mass 1 are distributed in a matrix inside the upper fractured rock mass 1 .

Embodiment 3

[0036] The difference between this embodiment and the above two embodiments is:

[0037] The roughness of the upper and lower fissure medium contact surfaces 7, the surface roughness of the groove of the sealing ring 5 and the surface roughness of the water flow medium inside the sealing ring 5 are all in the range of 0-1.6; the diameter of the sealing ring 5 ranges from 0.3m -0.6m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com