Adaptive closed fixture for live working insulator of power transmission line

A technology for live work and transmission lines, applied in the direction of overhead lines/cable equipment, etc., which can solve problems such as inability to replace, inconsistent size of carrying tools, time-consuming and labor-intensive work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

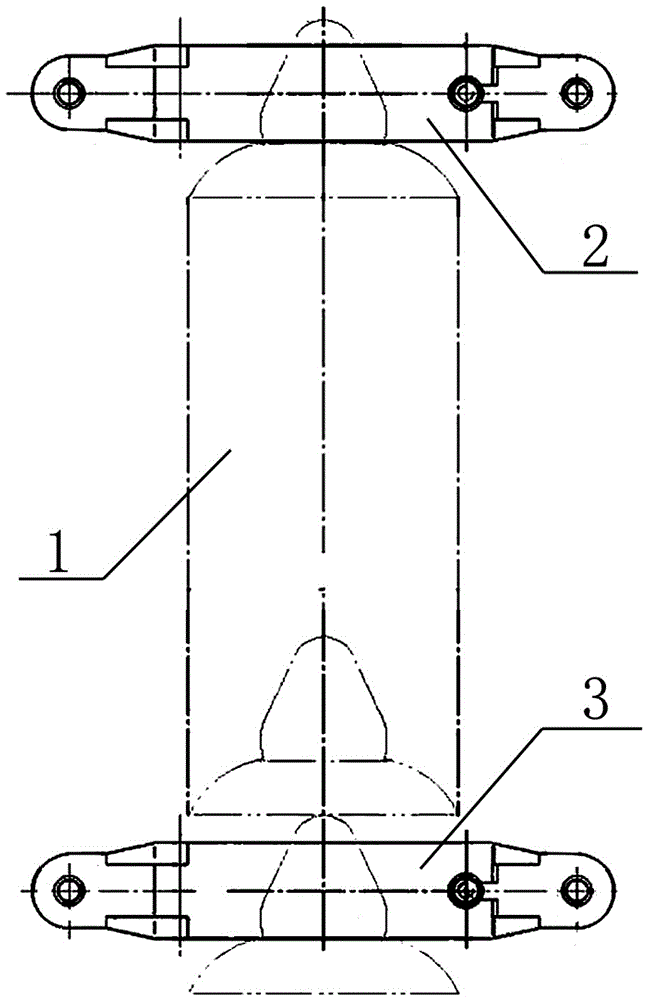

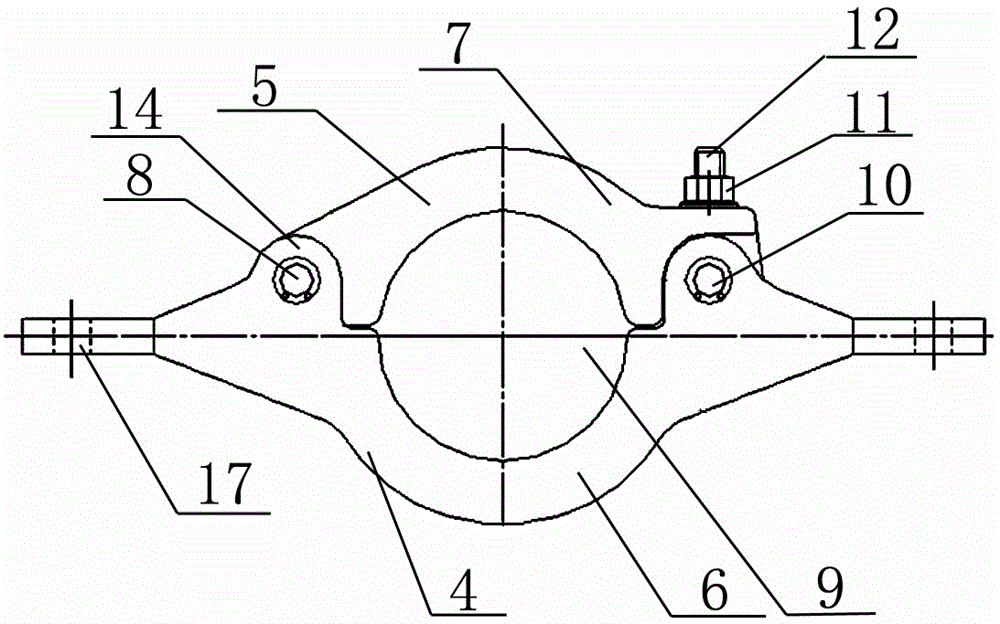

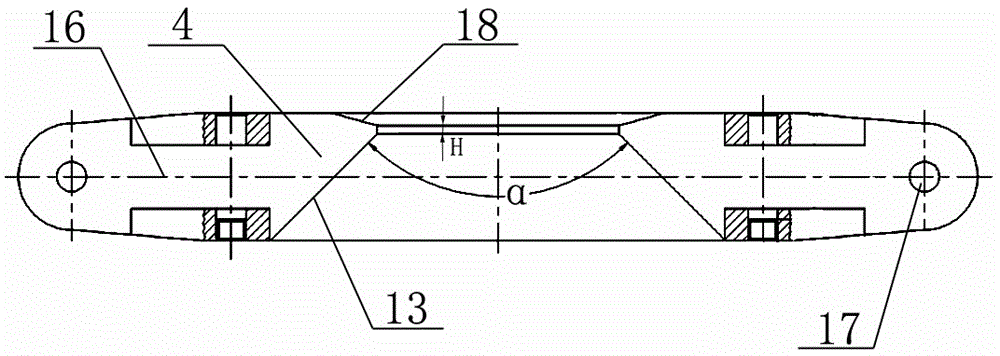

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown in the present invention, a self-adaptive closed clamp for live working insulators of transmission lines mainly includes a front clamp body and a rear clamp body respectively used on the front and rear steel caps of the insulator 1, and the front clamp body and the front clamp body respectively. The front card cover and the rear card cover that match the body and the rear card body, and constitute the front clamp 2 and the rear clamp 3 respectively; the front card body 4 and the front card cover 5, the rear card body 6 and the rear card cover 7 Respectively connected together through the pin shaft 8 at one end, see figure 2 shown; and the middle of the front card body 4 and the front card cover 5, the rear card body 6 and the rear card cover 7 are respectively provided with semicircular arc grooves of the same radius, and in the front card body 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com