Application system with cable-guided handling apparatus for moving an applicator

A technology of applying devices and manipulating devices, applied in spraying devices, manufacturing tools, program-controlled manipulators, etc., can solve problems such as troublesome removal, different, inconsistent paint quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

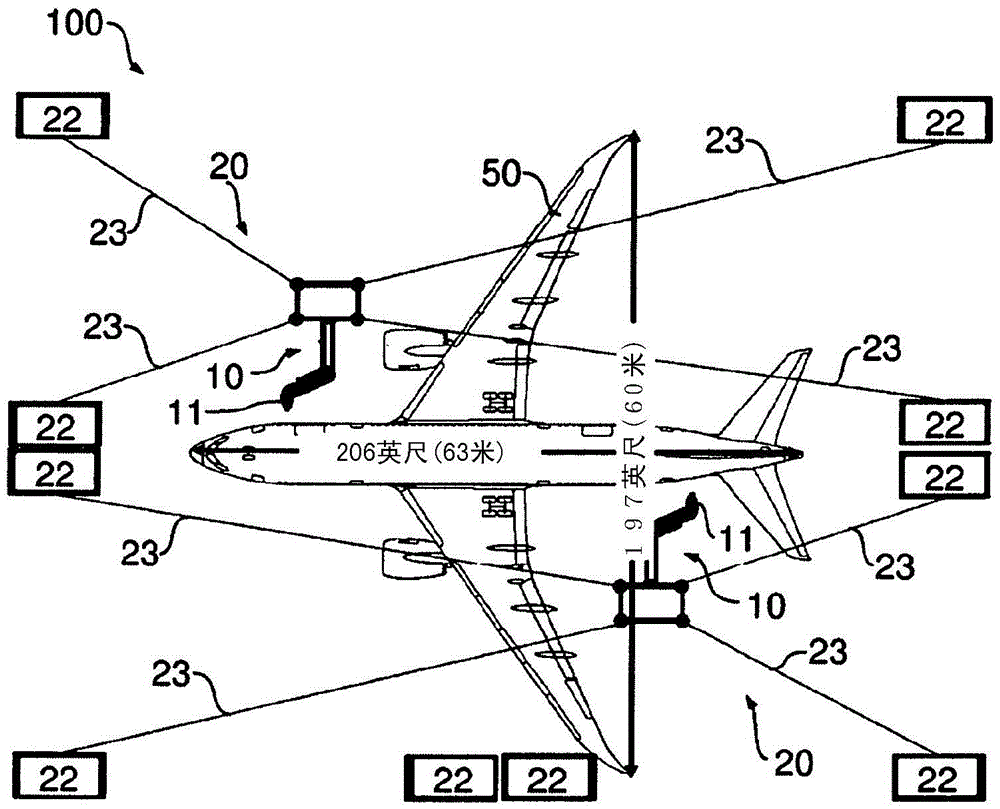

[0059] figure 1 A top view of an application system 100 according to one embodiment of the invention is shown. The application system 100 is used for coating, in particular painting, the surface of a large-area object in the form of a transport or passenger aircraft 50 . The transport or airliner has dimensions exceeding 50 m in length and width.

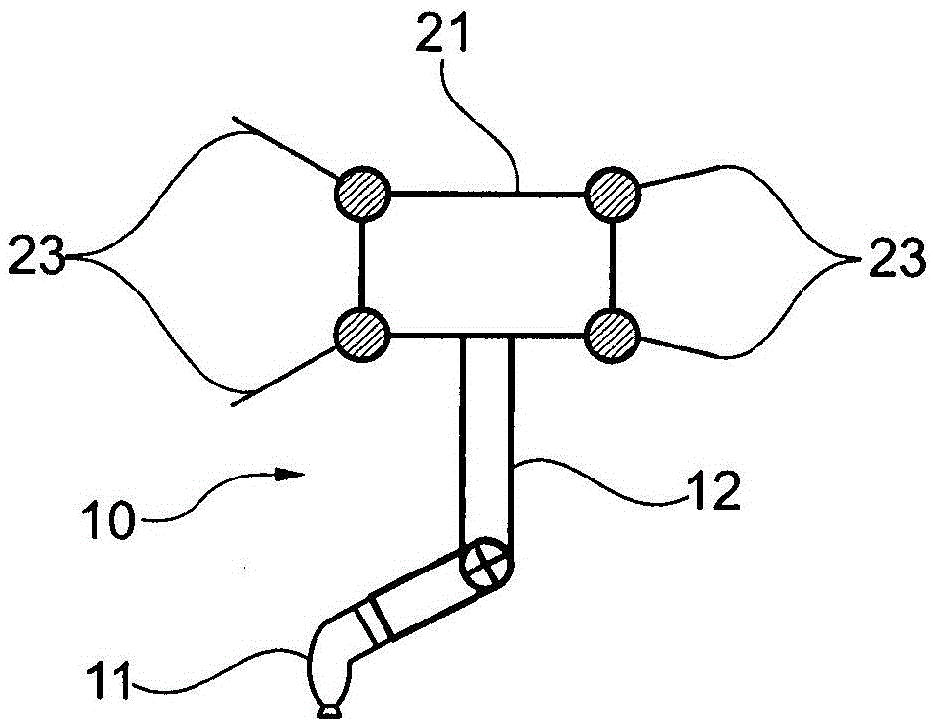

[0060] The application system 100 comprises two application devices 10 and two cable-guided handling devices 20 , in particular two cable robots or cable manipulators. The application devices 10 and the handling devices 20 are expediently designed identically, so that the following description refers only to one application device 10 and one handling device 20 .

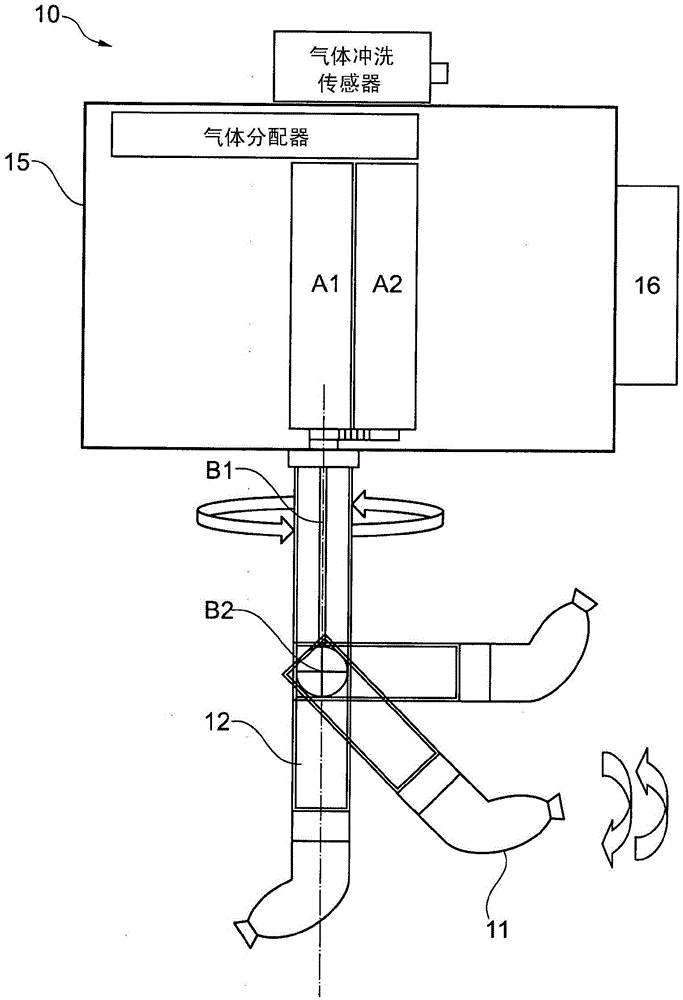

[0061] The application device 10 includes in particular an application device 11 for applying an application medium, in particular lacquer, to an object 50 . The applicator 11 is designed as an atomizer, in particular a rotary atomizer.

[0062] The manipulation device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com