An integrated molded slice clamping device

A clamping device and integrated technology, which are applied in the field of integrated forming slice clamping devices, can solve the problems of high requirements on assembly accuracy of parts and parts, and achieve the effects of simple structure, low cost and few parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

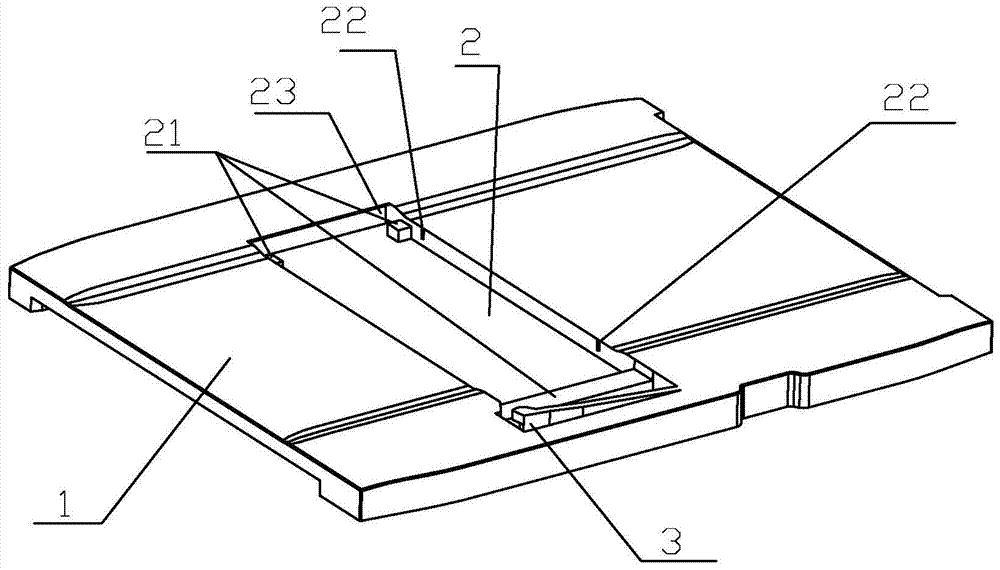

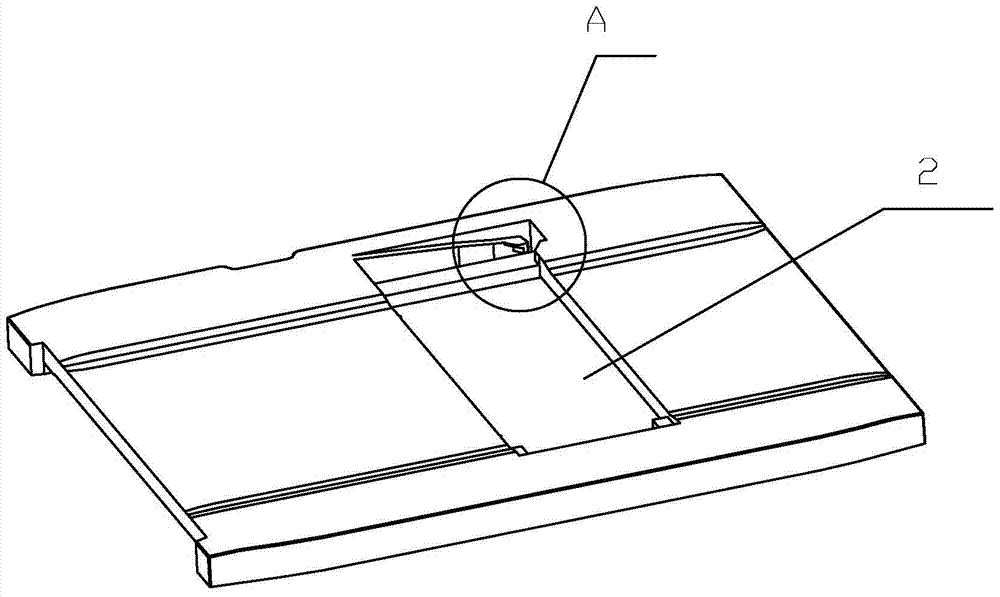

[0029] see Figure 1 to Figure 4 As shown, an integrated molded slice clamping device of the present invention includes a plate body 1 made of plastic integrated molding, and the plate body is integrally formed with a groove 2 adapted to the slice 4, and the groove 2 The bottom of the groove is used to support the slice 4, and at least one of the four side walls of the groove 2 is provided with an elastic part made of plastic integrally formed, and the elastic part can press the slice put into the groove. Press against the groove bottom and level of the groove in the groove.

[0030] The bottom of the groove 2 forms a through opening, and a plurality of bosses 21 are integrally formed around the bottom of the groove, and the upper end surfaces of the plurality of bosses 21 form the groove bottom of the groove 2 .

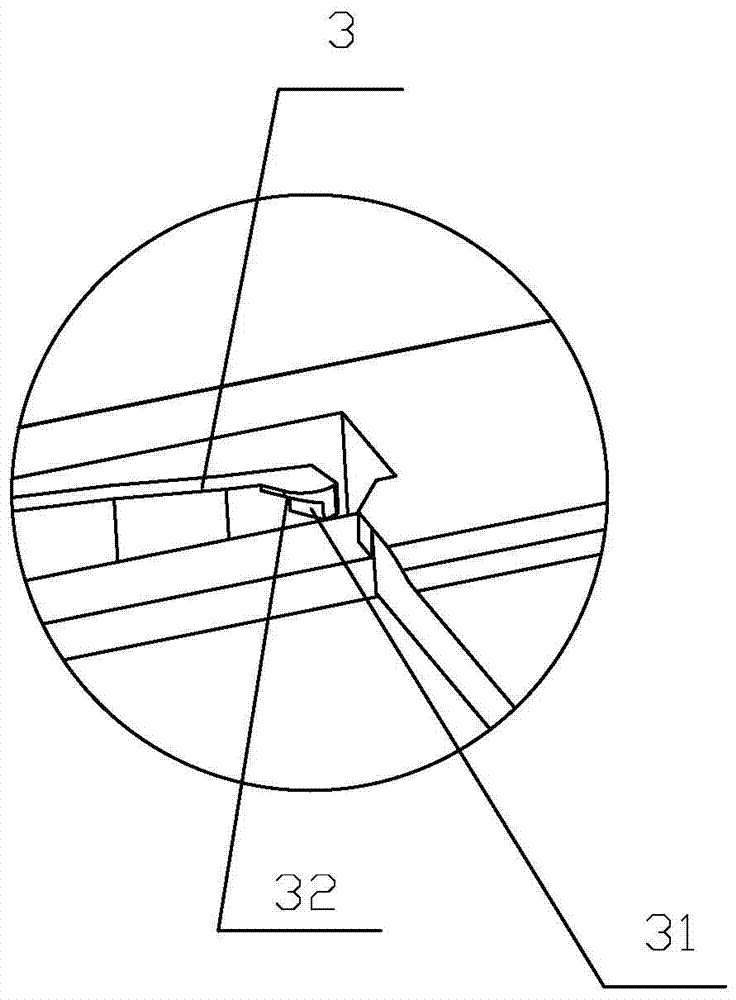

[0031] The groove includes two opposite wide groove walls and two opposite narrow groove walls, and the elastic member includes a first elastic member 3 arranged a...

Embodiment 2

[0039] see Figure 5 to Figure 7As shown, the one-piece molded slice clamping device of the present invention differs from Embodiment 1 in that three of the four side walls of the groove 2 are provided with plastic integrated molding. In addition to the first elastic member 3a at one of the narrow groove walls of the groove, there is also a second elastic member 3b at the other narrow groove wall of the groove, and a wide The third elastic part 3c at the groove wall place, wherein, the wide groove wall where the third elastic part 3c is located is not the same as the wide groove wall where the positioning rib 22 is located, so that it is convenient to utilize the third elastic part 3c to move the slice to Locate the convex ribs at 22 places and press them.

[0040] The first elastic member 3a has an oblique end face 3a1 for horizontally abutting the slices put into the groove against the groove and a pressing convex point 3a2 for pressing the slices put into the groove to the...

Embodiment 3

[0046] see Figure 8 to Figure 10 As shown, the one-piece molded slice clamping device of the present invention is different from the second embodiment in that the plate body 1 is provided with six grooves 2 for placing six slices.

[0047] The size of the groove 2 is processed according to the external dimensions of the standard slices, and the external dimensions of the slice 4 are 76x 26 (mm) in the national standard; of course, the number of grooves can also be determined according to actual needs, combined with dimensional accuracy and material properties , molding process, cost factors and other comprehensive considerations, it is recommended that no more than ten slices, then the number of slices 4 that can be clamped by the slice holding device should not exceed ten slices.

[0048] In the six slice clamping function scheme adopted in this embodiment, the six slices are arranged in a straight line. The overall appearance of the plate body 1 of the multiple slice clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com