An intelligent bin loading machine

An intelligent, rack-based technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of time waste, dust diffusion, inconvenient equipment operation, etc., and achieve simple and convenient operation, flexible movement and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

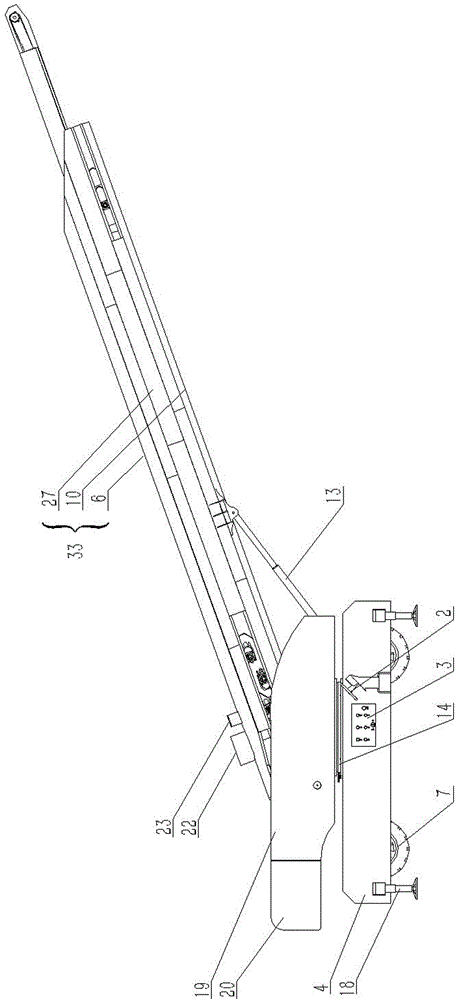

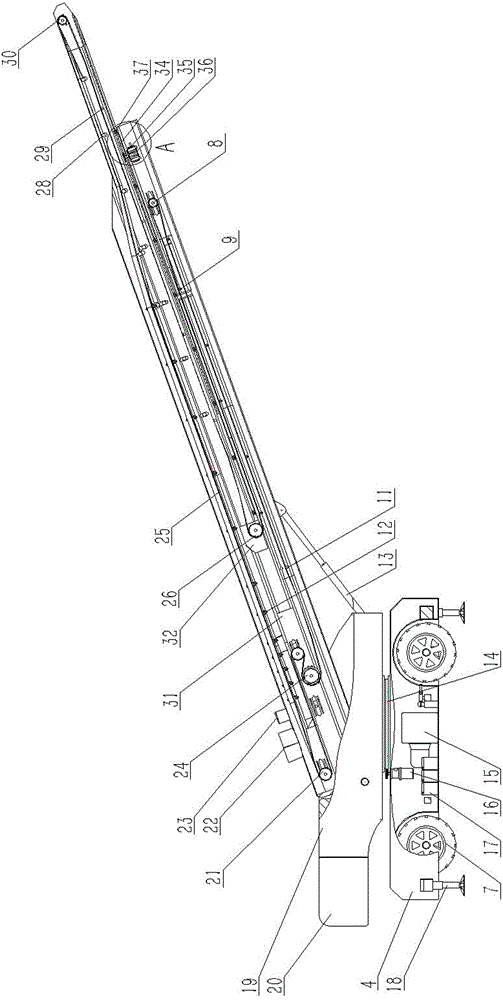

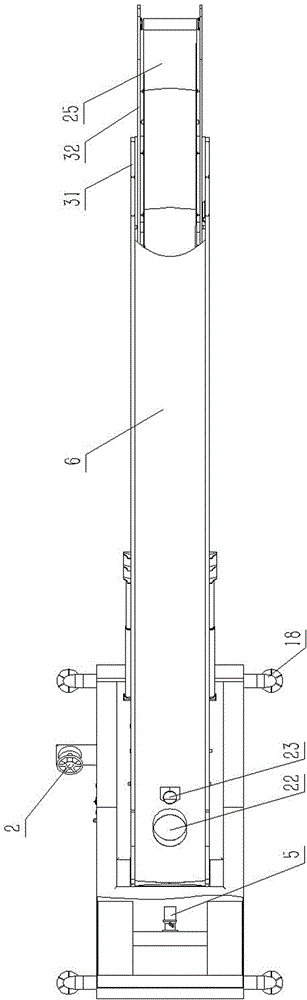

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] as attached Figure 1-6As shown, an intelligent binning machine includes a fixed base 4, a rotating base 19 that can rotate horizontally on the fixed base 4, a conveying mechanism that is arranged on the front of the rotating base 19, and a conveyor that is arranged on the fixed base 4. A power control mechanism for controlling the rotation of the rotating base 19 and the conveying mechanism for conveying materials. A turntable 14 is provided between the rotating base 19 and the fixed base 4, and the turntable 14 is a slewing support bearing. Walkable wheels 7 and supporting legs 18 supported on the ground are arranged under the fixed base 4 . The power control mechanism includes a rotary hydraulic motor 16 arranged on the fixed base 4 to control the rotation of the turntable 14, a travel hydraulic motor 5 for driving the wheels 7 to travel, a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com