Crane track change and docking device

A docking device, crane technology, applied in the direction of rail system, transportation and packaging, load hanging components, etc., can solve the problems that the rail cannot move horizontally and vertically, and the lifting equipment can only be used within a limited working range, etc. To achieve the effect of convenient on and off, precise positioning and docking, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

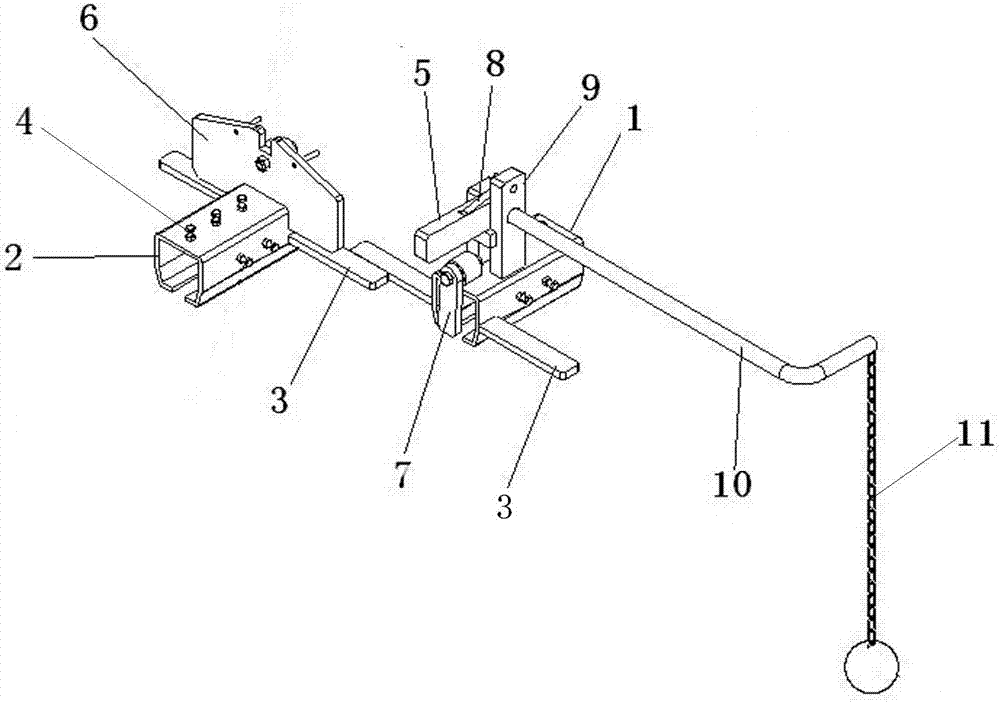

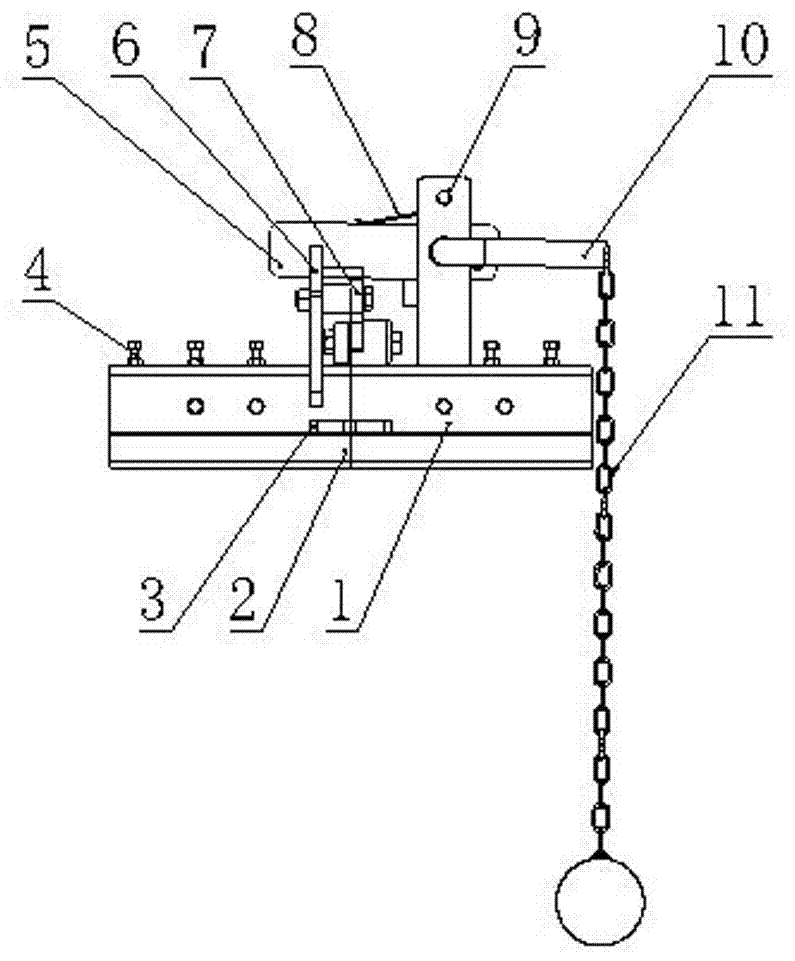

[0014] figure 1 It shows an embodiment of a crane rail exchange docking device of the present invention, which includes two butt joint slide rails 1 and 2 butt joint slide rails 2, and the docking slide rail 2 2 is fixed with a positioning groove Plate 6, the positioning groove plate 6 is provided with a positioning groove, and the corresponding docking slide rail 1 is provided with a positioning plate 5 inserted into the positioning groove, and the positioning plate 5 is arranged on the docking slide rail 1 together with the manual lever 10. On the positioning plate fixing seat 9 on. One end of the docking slide rail 1 and the docking slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com