A method for implementing a tool-type safety flat net

An implementation method and a tool-type technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to effectively guarantee the personal safety and injury of people falling from high altitudes, and achieve the effect of convenient dismantling and slowing down the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

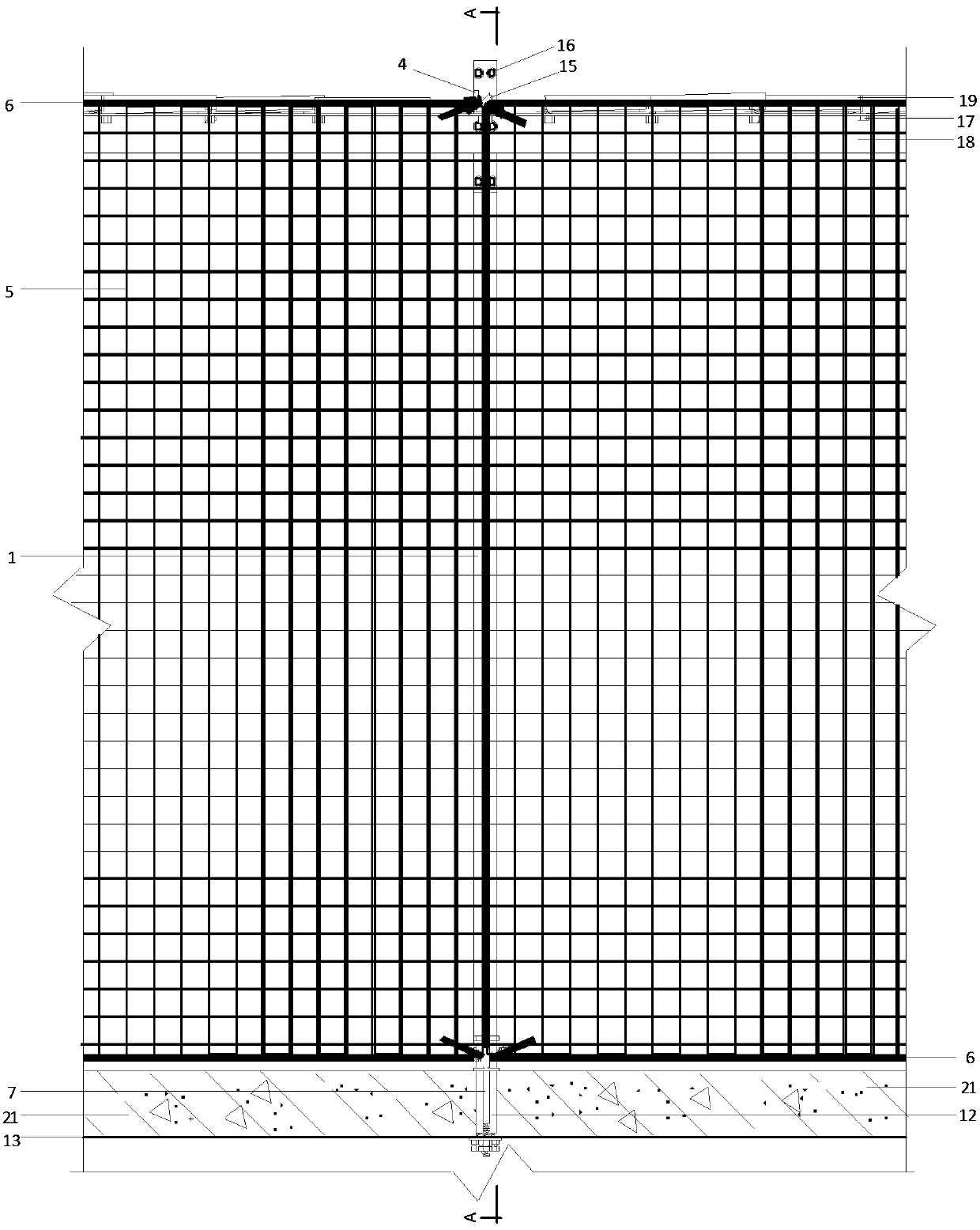

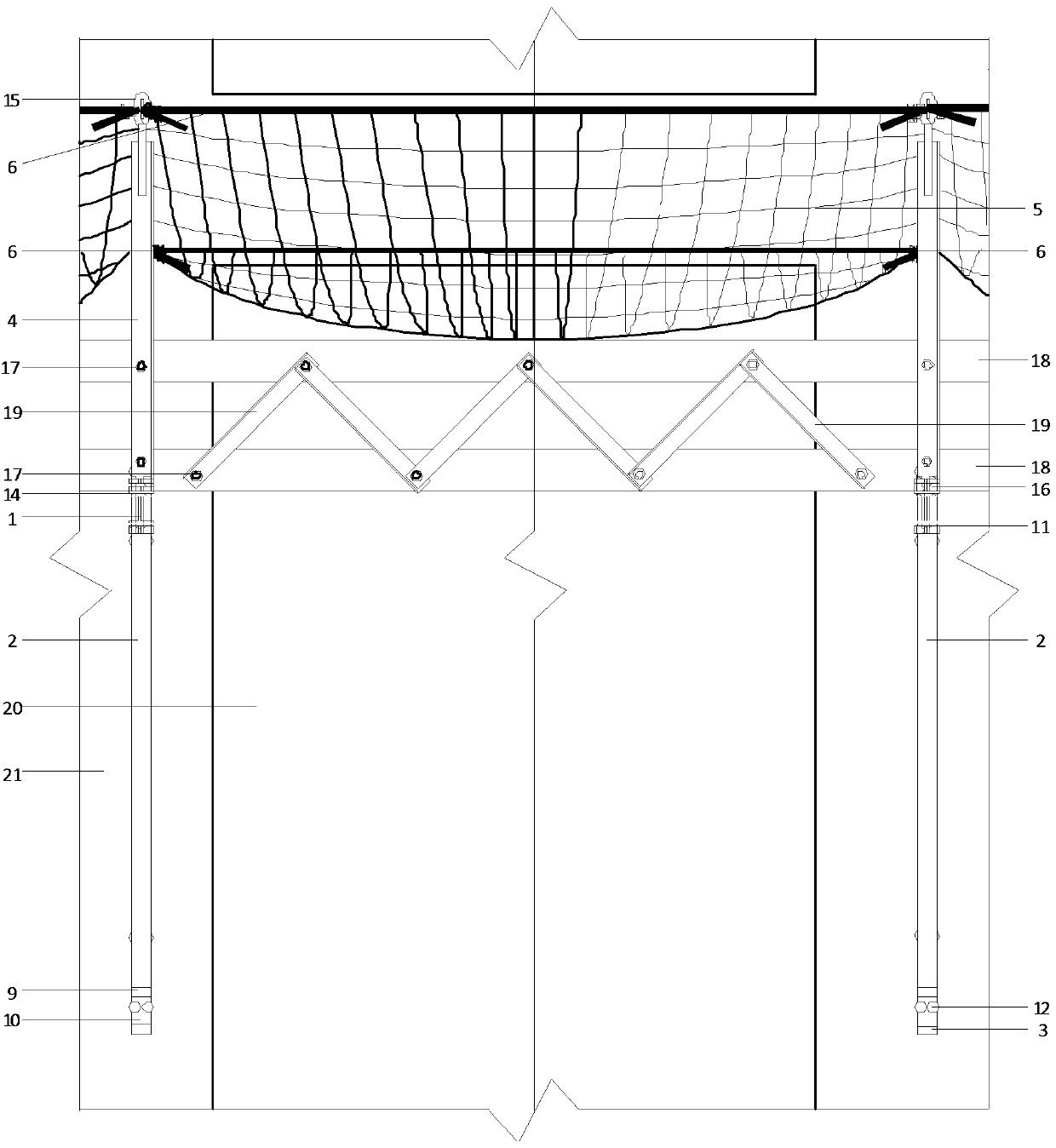

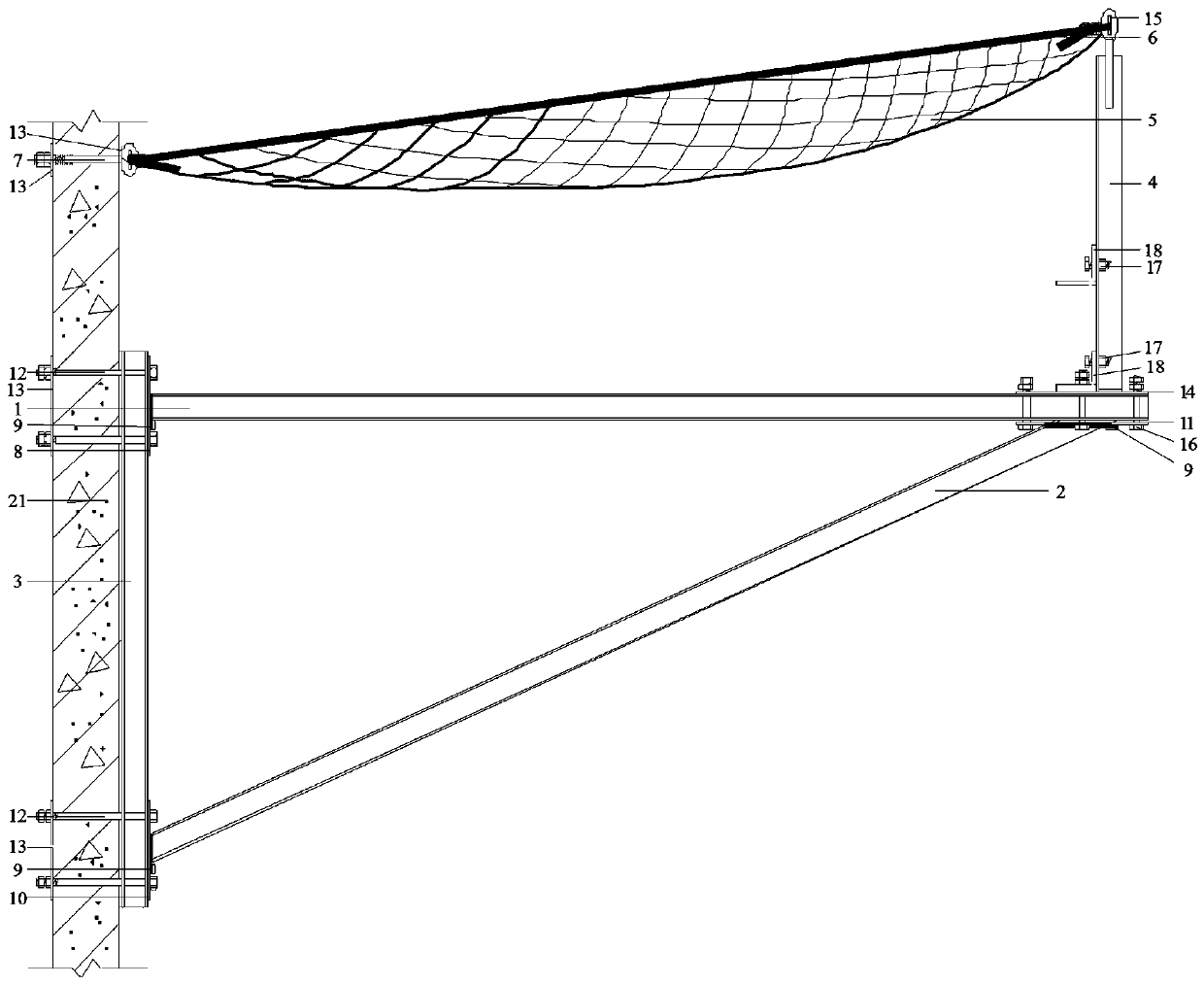

[0035] A method for implementing a tool-type safety flat net, comprising the following steps:

[0036] 1) Weld the cantilever beam 1, the oblique support 2 and the vertical rod 4 to their corresponding steel plate bases respectively, and then connect the bottom of the fixed end of the cantilever beam 1, the bottom of the fixed end of the oblique support 2 and the outside of the cantilever end of the oblique support 2 The surface of the support at the junction of the steel plate base is welded with a shear reinforcement belt 9 to improve the support strength for the cantilever beam and the oblique support;

[0037] 2) Pass the M20 wall-through bolts 12 sequentially through the cantilever beam base 8, the attached wall rod 3, the concrete structure 21 below the edge opening 20 and the steel backing plate 13 and fasten them, and tighten them with nuts; The wall bolts 12 pass through the vertical base 10 of the oblique support, the attached wall rod 3, the concrete structure 21 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com