Field replaceable module

An on-site, radiator technology, applied in the field of avionics system, can solve problems such as heat pipe damage, achieve the effect of improving reliability, avoiding fatal damage, and satisfying high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The solution provided in this specification will be described below with reference to the accompanying drawings.

[0028] An embodiment of the present invention provides a field replaceable module, and the field replaceable module may be abbreviated as an LRM module.

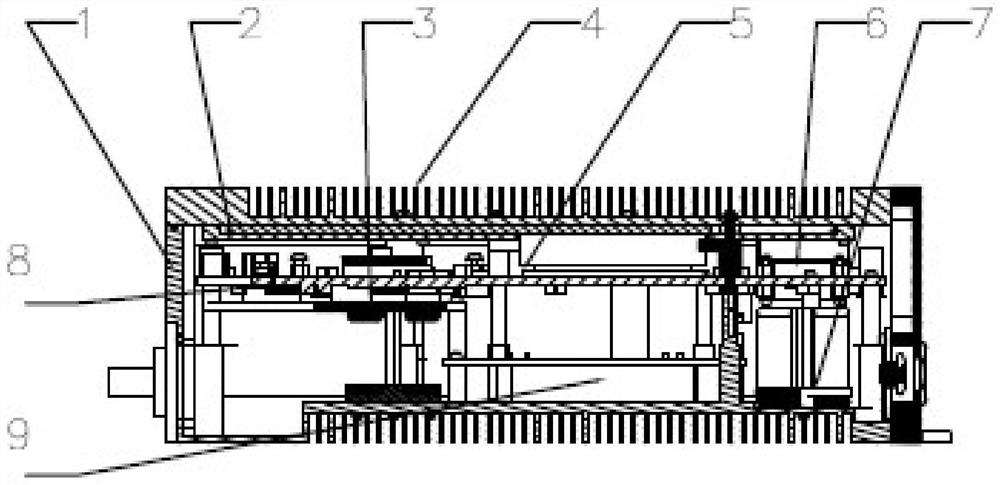

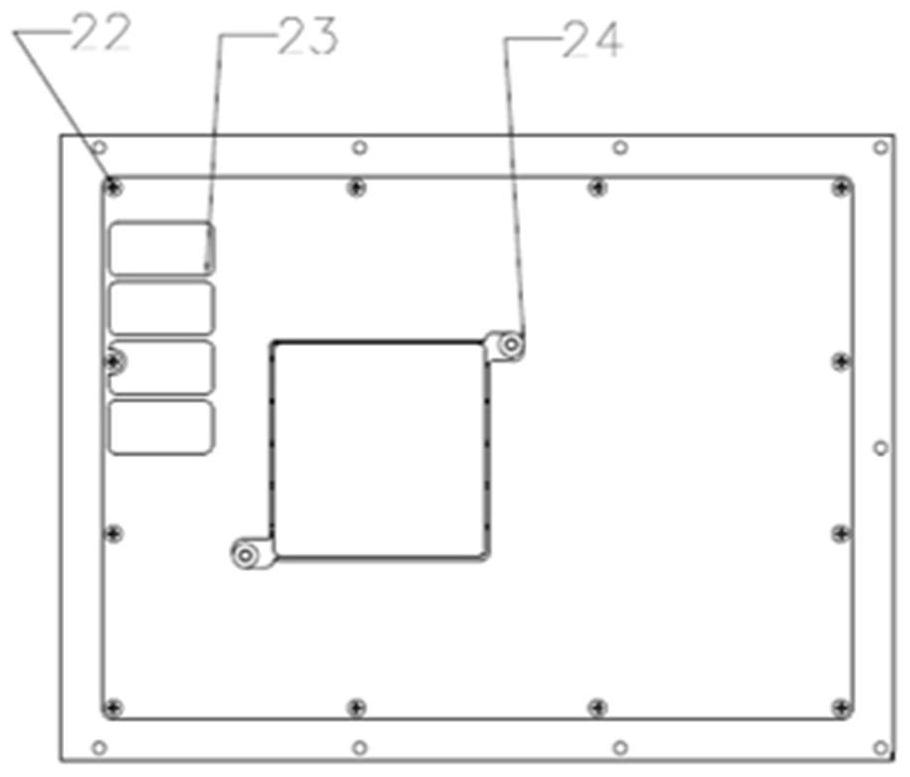

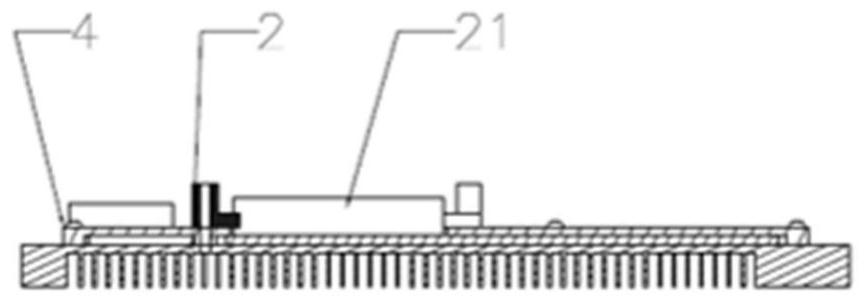

[0029] see Figure 1 ~ Figure 4b , the field replaceable module provided by the embodiment of the present invention includes a heat dissipation bottom cover 1 and a heat dissipation top cover 4, the heat dissipation bottom cover 1 is a semi-closed cubic structure with an open top, and the top of the heat dissipation bottom cover 1 and the heat dissipation The top cover 4 is fixedly connected to form a closed cubic structure, and the heat dissipation bottom cover 1 and the heat dissipation top cover 4 are provided with heat dissipation fins;

[0030] The module also includes: a main board 8, a cpu 5, a power supply chip 6 and a bridge chip group 37 arranged inside the closed cube structure; the cpu is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com