Molding method of integrated cold shield for infrared detector

A technology of infrared detector and molding method, which is applied in the field of materials, can solve the problems that are not conducive to the life of Dewar vacuum, cannot complete the integrated molding process, and the detector Dewar vacuum fails, so as to achieve the effect of maintaining a long life of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention. For the sake of clarity and simplicity, detailed descriptions of known functions and constructions in the devices described herein will be omitted when it may obscure the subject matter of the present invention.

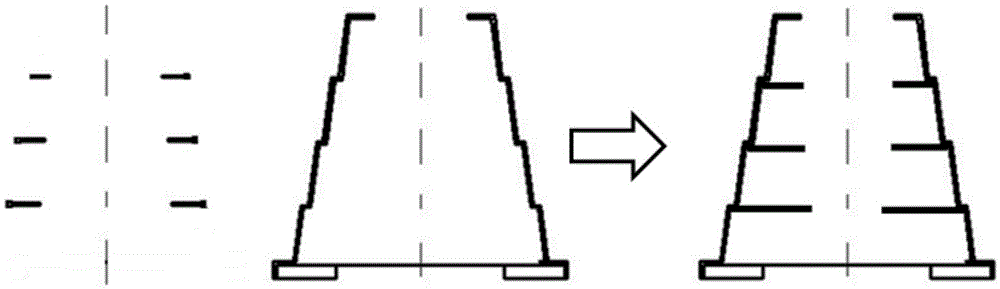

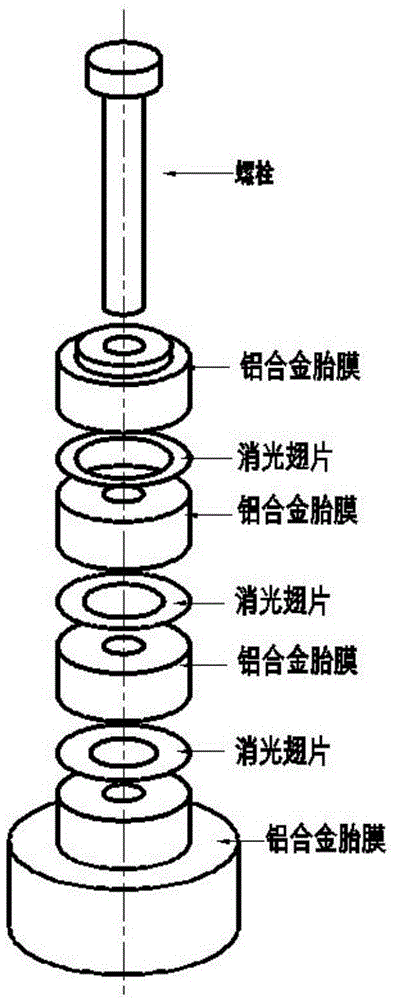

[0025] In order to solve the problem that excessive glue is introduced into the fin bonding process in the prior art, thus reducing the vacuum life of the Dewar, the present invention provides a method for forming an integrated cold screen for infrared detectors. Due to the extinction of the electroformed cold screen of the present invention The fins are integrated with the outer wall material without welding seams, glue joints and screw threads....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com