Photovoltaic module grounding system employing grounding connection plates

A photovoltaic module and grounding system technology, applied in the direction of photovoltaic power generation, photovoltaic modules, support structures of photovoltaic modules, etc., can solve the problems of large labor consumption and achieve the effect of large resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

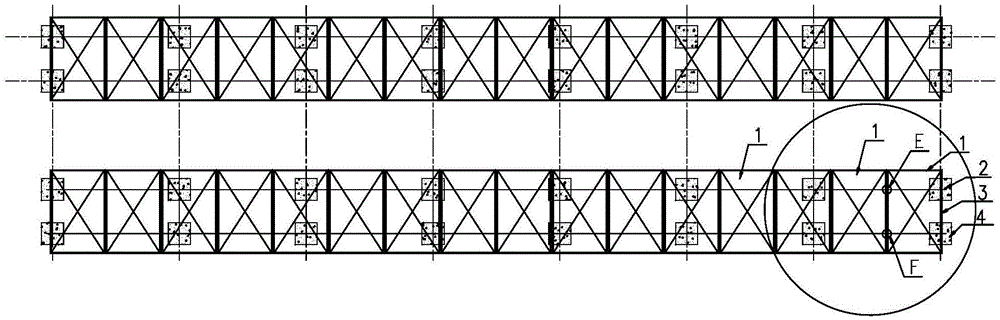

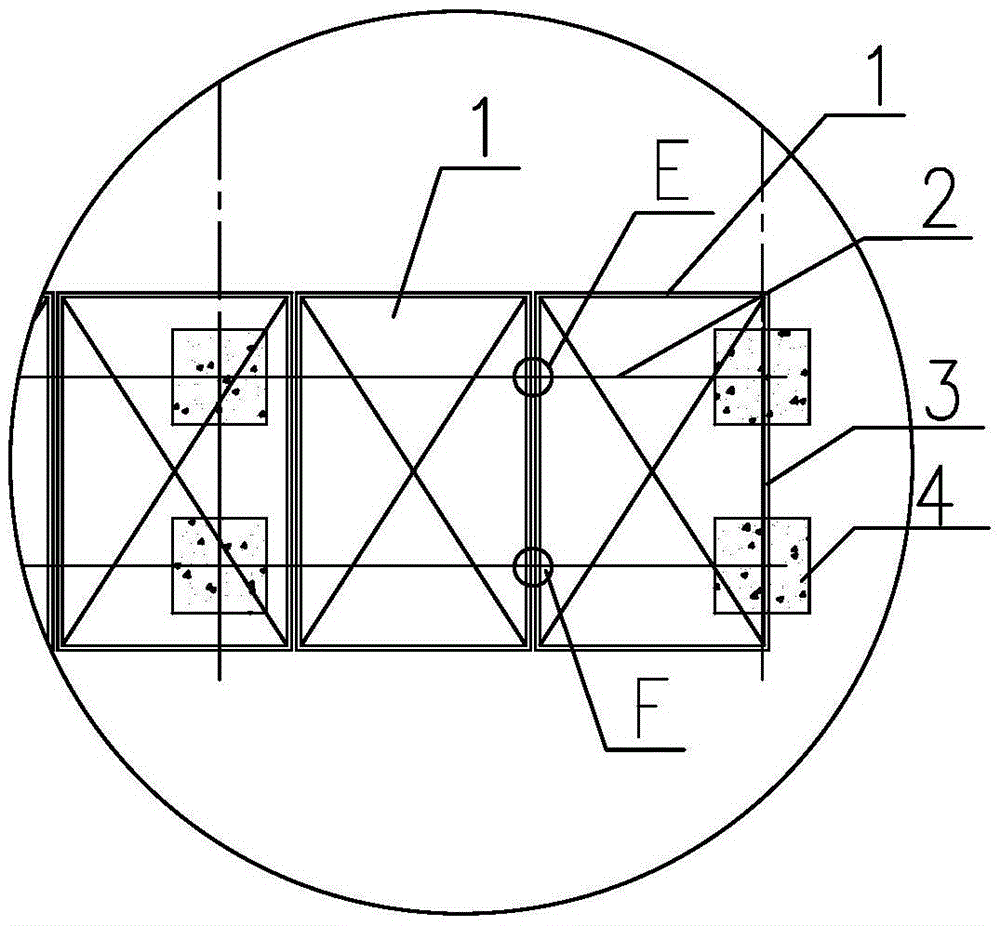

[0025] Picture 1-1 It is a front view of a schematic diagram of installation arrangement of photovoltaic modules of the present invention. Figure 1-2 for Picture 1-1 A partial enlargement of the . Such as Picture 1-1 and 1-2 As shown: the photovoltaic modules 1 in the present invention are installed side by side on a shelf made of beams 2 and slanted beams 3, and the two small circles in Figure 1 are the installation positions of the ground connection piece. Install two sets of ground straps (eg Picture 1-1 and 1-2 at "E" and "F" in ).

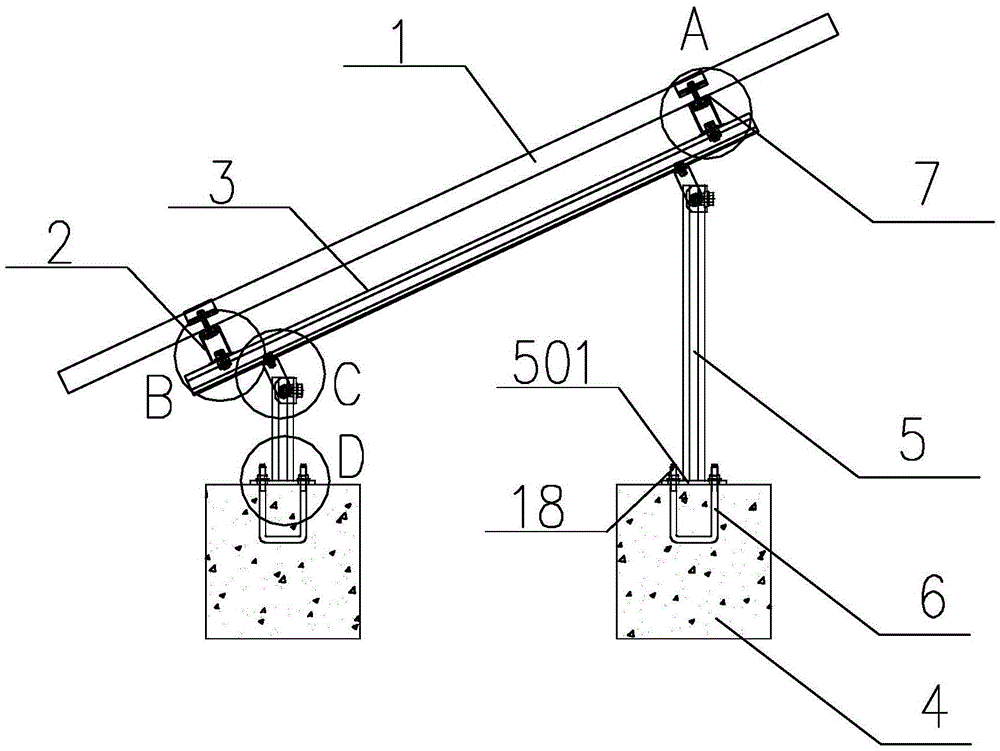

[0026] figure 2 It is the right side view of Fig. 1 in the present invention. Such as figure 2 As shown, the load-bearing block 4 is a concrete load-bearing block, and the column 5 is a stand with a bottom plate 501. The hollow "U"-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com