Compact locking and looseness-preventing device and dismantling tool thereof

A compact technology for dismantling tooling, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of no structure in locking and anti-loosening methods, internal parts cannot be seen, and anti-loosening problems cannot be verified, etc., to achieve Excellent locking and anti-loosening effect, easy processing and maintenance, excellent locking and anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

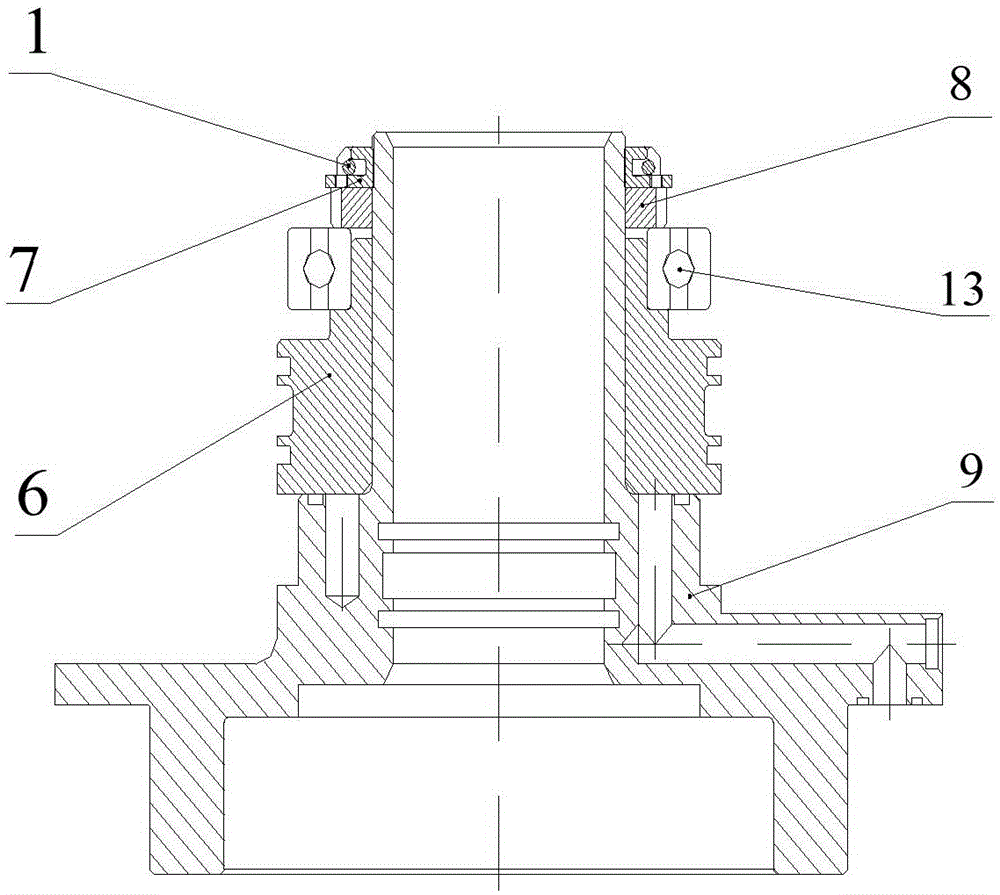

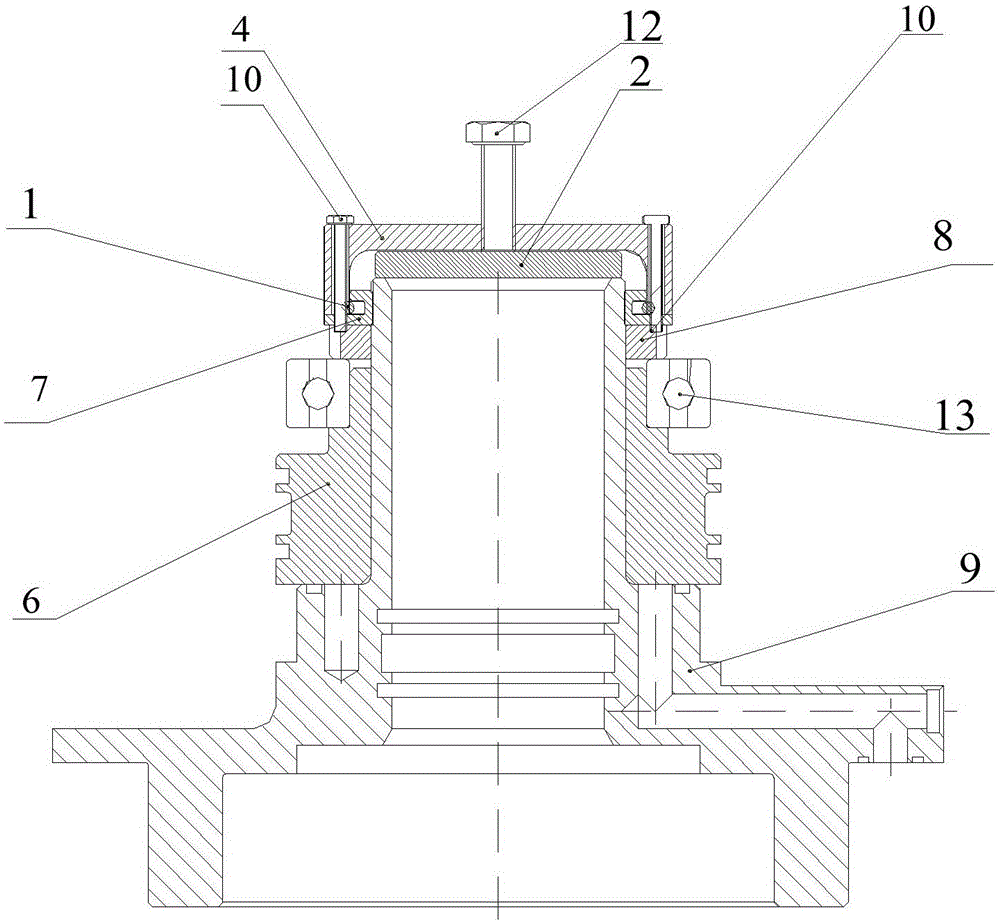

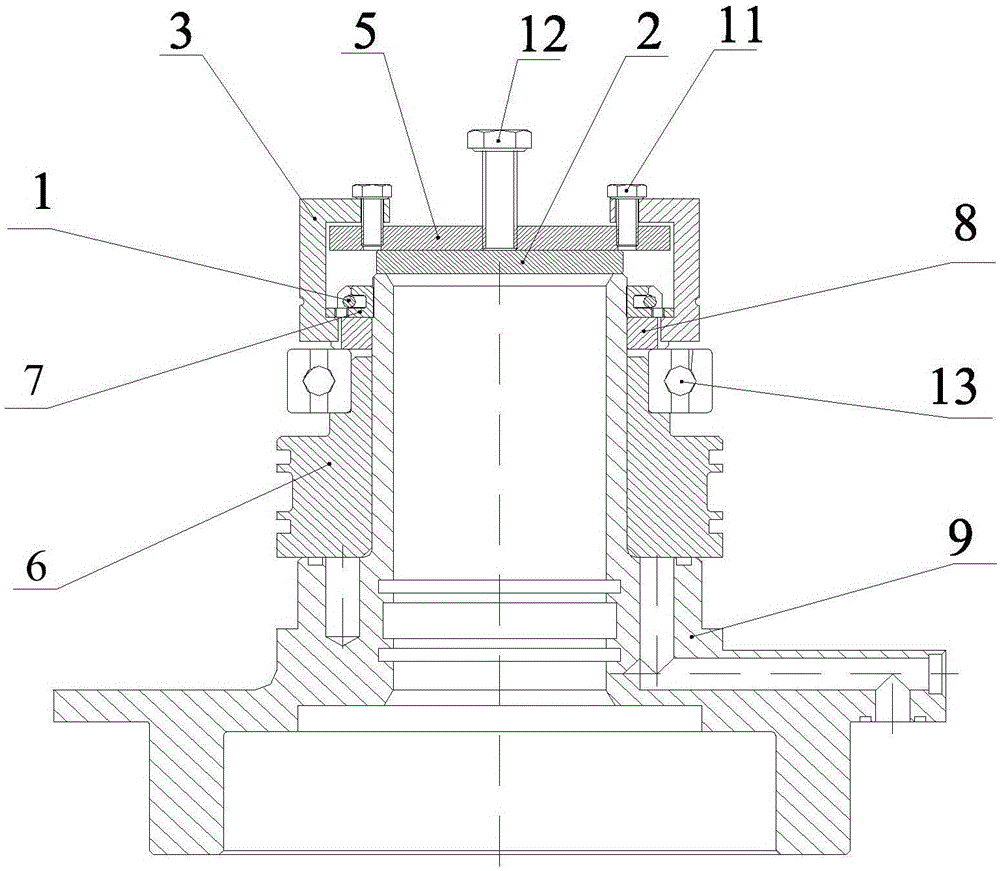

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] The invention provides a compact locking and anti-loosening device suitable for medium-sized and heavy-duty mechanical structures that need to fix the fastener on the shaft. The device ensures the axial movement and radial movement of the locked fastener from the structural design There is a special structure to prevent the occurrence of loosening, which solves the problem of failure of conventional anti-loosening measures caused by excessive loosening load. Today, with the vigorous development of medium and heavy armored vehicles, this kind of locking and anti-loosening device can be widely used in powertrain and transmission assembly.

[0034] The locking and anti-loosening device has designed a targeted structure for the possible axial movement and radial rotation loosening of the fastened parts, and uses the large-strength small-module internal spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com