A capillary tube, an irrigation system using the capillary tube for water delivery, and a warehouse dehumidification device using the capillary tube

A technology of capillary action and capillary materials, applied in watering devices, air conditioning systems, air humidification systems, etc., can solve problems such as not using production practices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

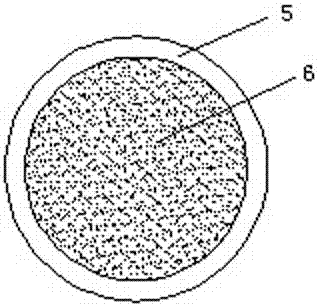

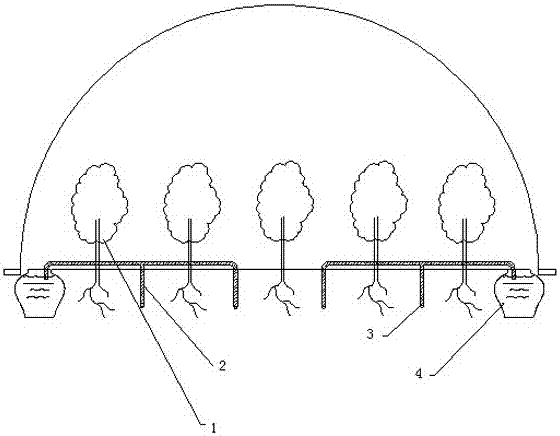

[0027] Such as figure 1 Among them, a capillary tube 2 includes a hose 5 and a capillary material 6 filled in the hose 5. The capillary material 6 is collodion or sponge, and moderate extrusion has little effect on the water absorption performance of the material.

[0028] Preferably, the inner wall of the hose 5 is provided with a continuous spiral.

[0029] Preferably, at least one end of the hose 5 is provided with a filter screen, which can filter impurities in the water to prevent impurities from entering the capillary material 6 and causing pores of the capillary material 6 to be blocked.

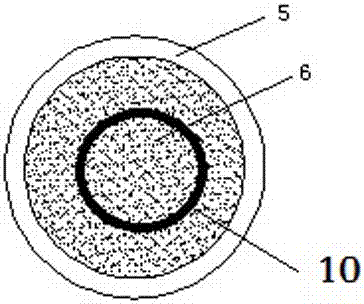

[0030] Such as figure 2 Among them, there is at least one sleeve 10 inside the hose 5, the sleeve 10 is filled with capillary material 6, the gap between the sleeve 10 and the hose 5 is filled with capillary material 6, and a blocking plate is set at one end of the sleeve 10 to prevent the sleeve from 10, and the capillary material 6 filled in it plays a capillary role, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com