Chain dismantling device for motorcycle maintenance

A technology of motorcycles and chains, which is applied in vehicle maintenance/repair, vehicle maintenance, transportation and packaging, etc. It can solve the time-consuming and labor-intensive problems of maintenance personnel, and achieve the effect of overcoming time-consuming, labor-intensive and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

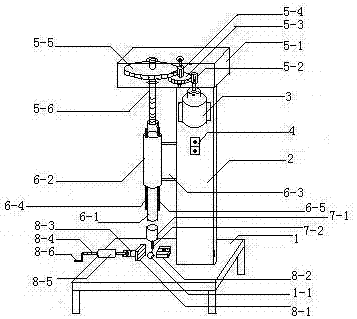

[0015] figure 1As shown in , the chain dismantling device used in motorcycle maintenance is composed of workbench 1, column 2, motor 3, power switch 4, deceleration mechanism, guide mechanism, ejector mechanism and clamping mechanism. Workbench 1, The column 2, deceleration mechanism, guide mechanism, ejector mechanism, and clamping mechanism are made of metal. There is an opening 1-1 in the middle of the upper part of the workbench 1. The column 2 is installed on the right end of the upper part of the workbench 1. The motor 3 is installed on the column. 2. The upper part of the front end, the power switch 4 is installed in the middle part of the front end of the column 2, and the reduction mechanism consists of a gear box 5-1, a driving gear 5-2, a first driven gear 5-3, a second driven gear 5-4, and a third driven gear. The moving gear 5-5 and the outer wire shaft rod 5-6 are composed of a bearing respectively installed at the left part and the upper and lower ends of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com