Special-shaped tool grinding machine

A tool grinding machine and special-shaped technology, which is applied to drilling accessories, metal processing equipment, boring machine/drilling machine parts, etc., can solve the problems of increased loss of drill bits, scrapped drill bits, and high price, so as to prolong the service life and ensure accurate repair. Grinding and improving the effect of grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

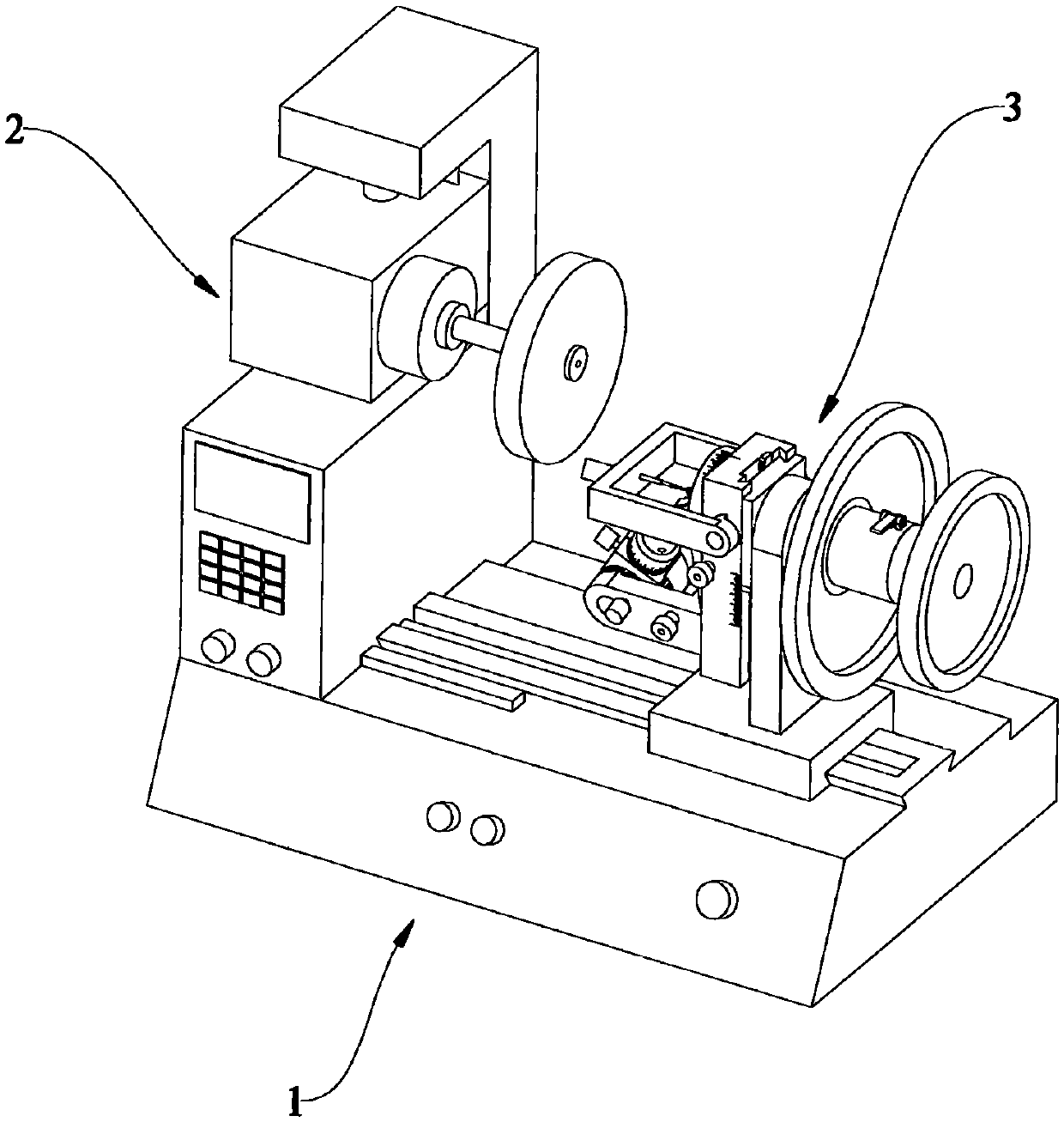

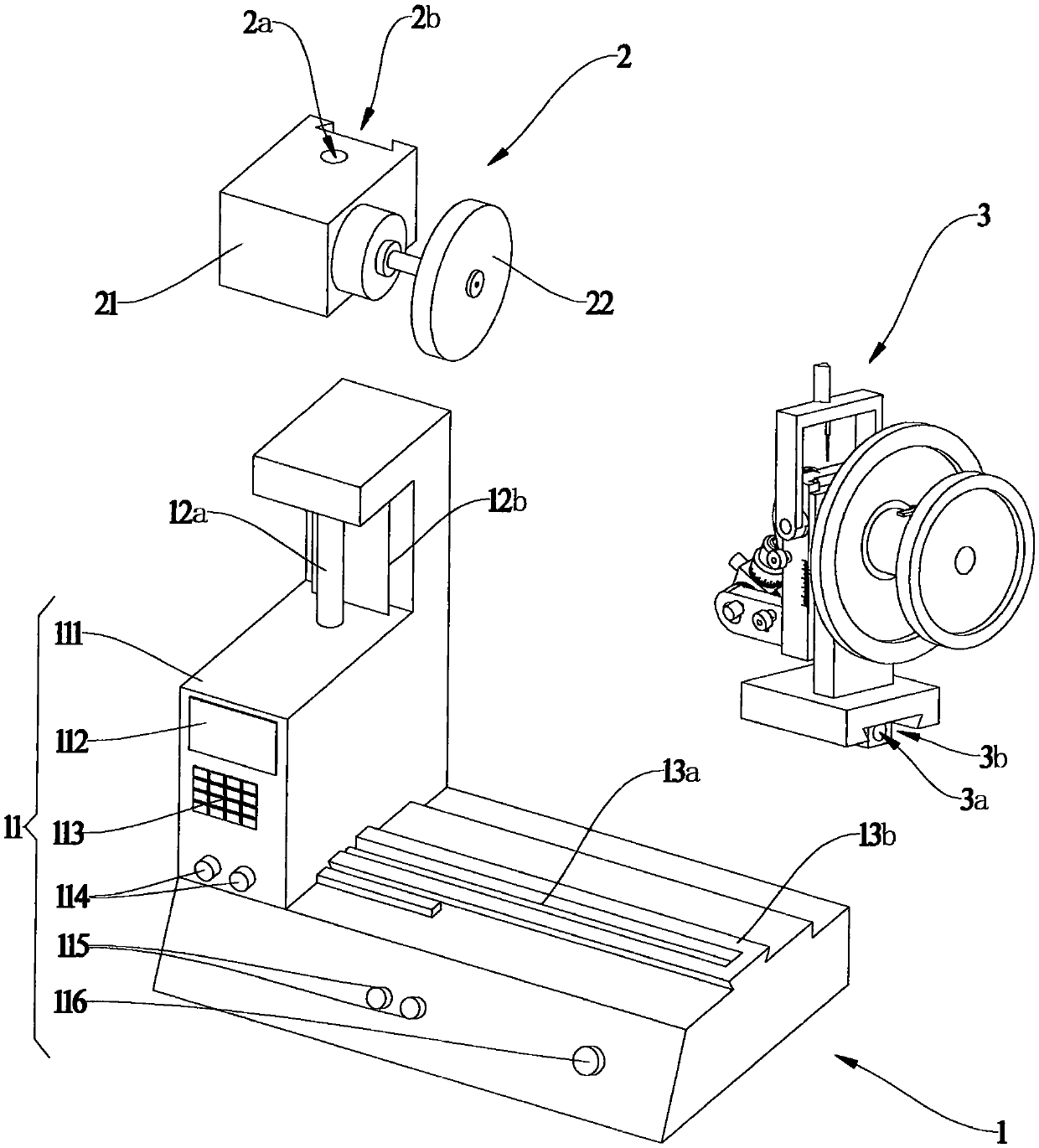

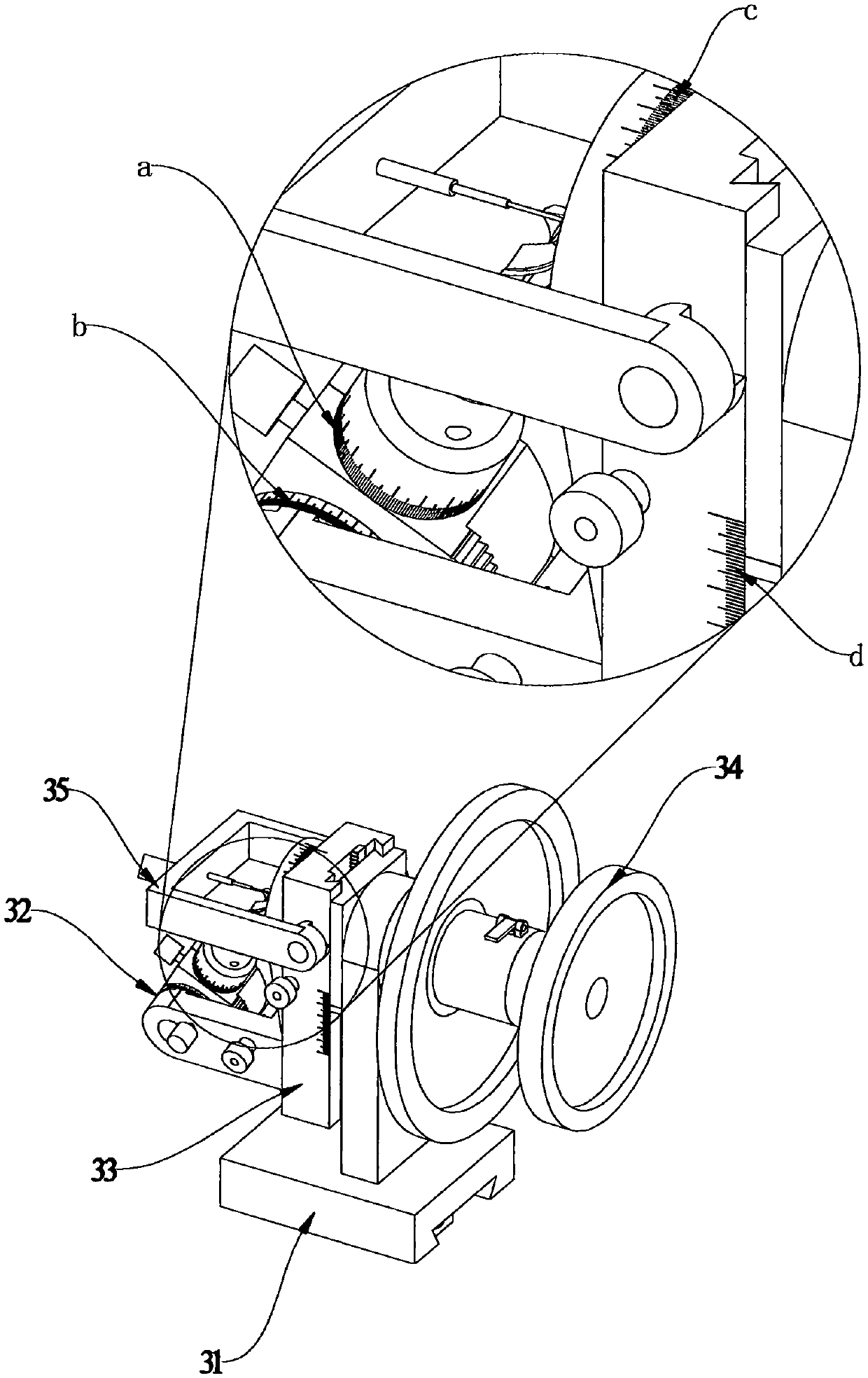

[0052] Such as Figure 1-13 As shown, an embodiment of the present invention includes a base part 1, a grinding part 2 and a table part 3, the grinding part 2 and the table part 3 are respectively movably connected to the base part 1, and the grinding part 2 includes a power Device 21 and grinding wheel 22, power unit 21 is a motor, and grinding wheel 22 is an emery wheel. Among them, the workbench part 3 is the most critical part, mainly including the workbench base 31, the top angle adjustment assembly 32, the relief angle adjustment assembly 33, the radius adjustment assembly 34 and the calibration positioning assembly 35, as follows:

[0053] Vertex adjustment assembly 32: used to clamp the drill bit 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap