a tubeless tire

A tire and inner tube technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of insufficient anti-skid ability, poor grip ability, etc. Improved grip, good drainage and self-cleaning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

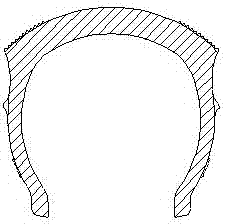

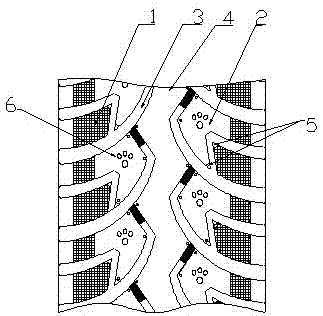

[0007] figure 1 shows the cross-sectional structure of the tubeless tire of the present invention, figure 2 It shows the partially expanded structure of the crown of the tubeless tire of the present invention. The crown has a central top surface 4, side top surfaces 2 and shoulders 1 arranged continuously in a zigzag type, and is characterized in that: the crown has a zigzag type Continuously arranged central top surface 4, side top surface 2 and tire shoulder 1 are characterized in that: the top of the crown is composed of central top surface 4 arranged continuously in a zigzag manner along the circumferential direction and a central top surface continuously arranged in zigzag type The top surface 4 is composed of a plurality of side top surfaces 2 arranged at intervals along the circumferential direction. The side top surface 2 includes a triangular head and a belt-shaped extension connected to the triangular head and extending to the shoulder 1. The tire shoulder 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com