Oil and gas suspension test equipment

A testing equipment and technology of hydro-pneumatic suspension, applied in the direction of vehicle suspension/shock-absorbing mechanism testing, etc., can solve the lack of research on hydro-p Research on vehicle coupling characteristics, etc., to achieve the effect of test switching, test stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

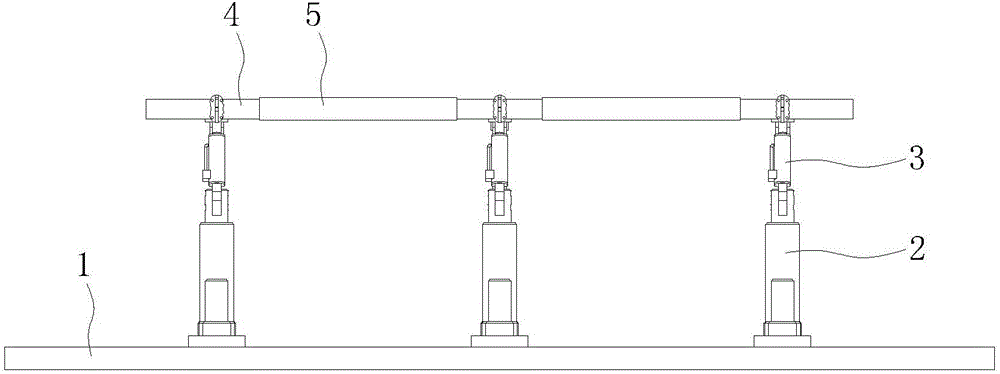

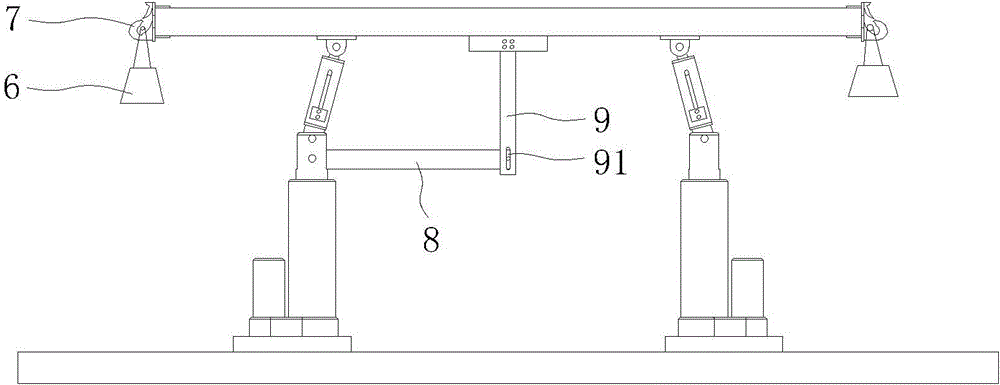

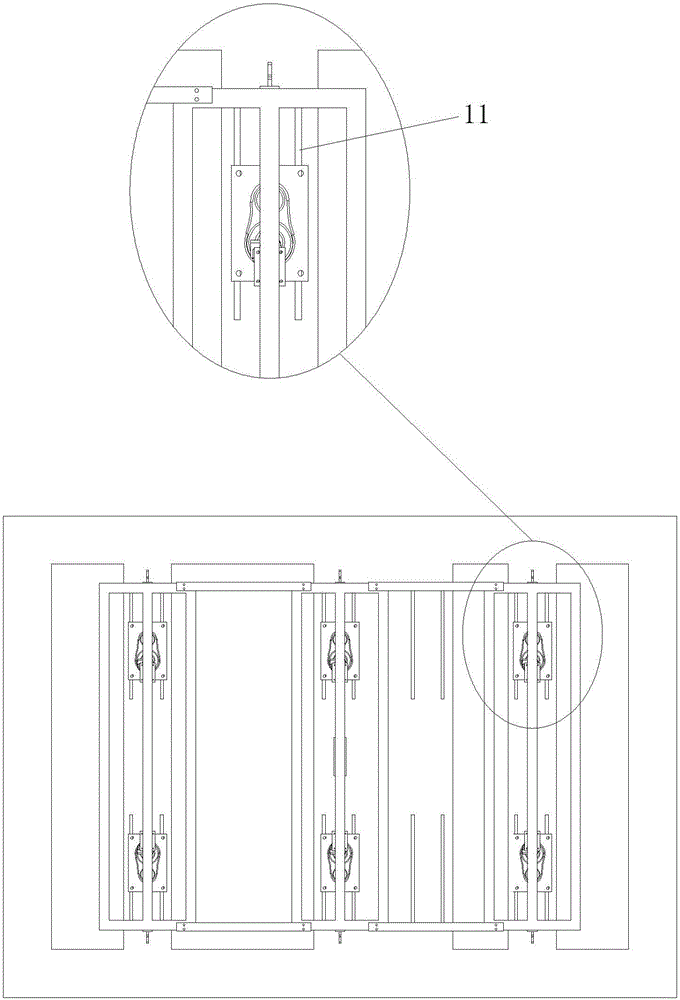

[0022] See 1 and figure 2 , the present invention relates to a kind of oil-pneumatic suspension testing equipment, and its preferred embodiment includes a base plate 1, a plurality of vibration devices 2, a single-axle frame 4, a frame connecting rod 5, a stabilizer bar 8, a mounting rod 9 and an oil-pneumatic suspension Cylinder 3.

[0023] Several vibration excitation devices 2 are installed on the bottom plate 1, every two vibration excitation devices 2 form a group of vibration excitation shafts, several groups of vibration excitation shafts are arranged at intervals along the length direction of the bottom plate 1, and the two vibration excitation devices 2 in each group of vibration excitation shafts Distributed at intervals along the width direction of the bottom plate 1; the rod end of each excitation device 2 is hinged to an oil-pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com