Clamping frame for vertically storing thin plates

A clamping frame and thin plate technology, which is applied in the field of thin plate clamping and storage equipment, can solve the problems of not being suitable for modern production, occupying a large space, and thin plate parts are prone to rust, so as to improve the utilization rate of equipment and avoid occupying a large space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means and creative features of the present invention easy to understand, the present invention will be further explained below.

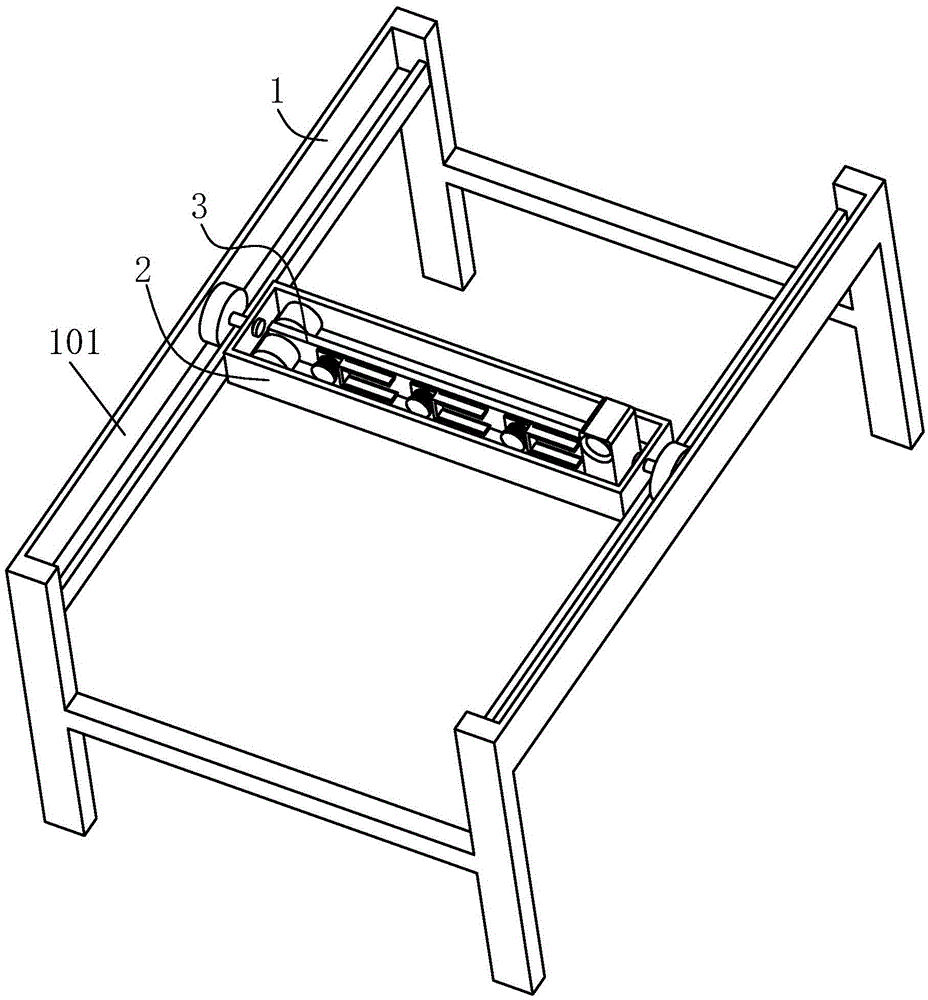

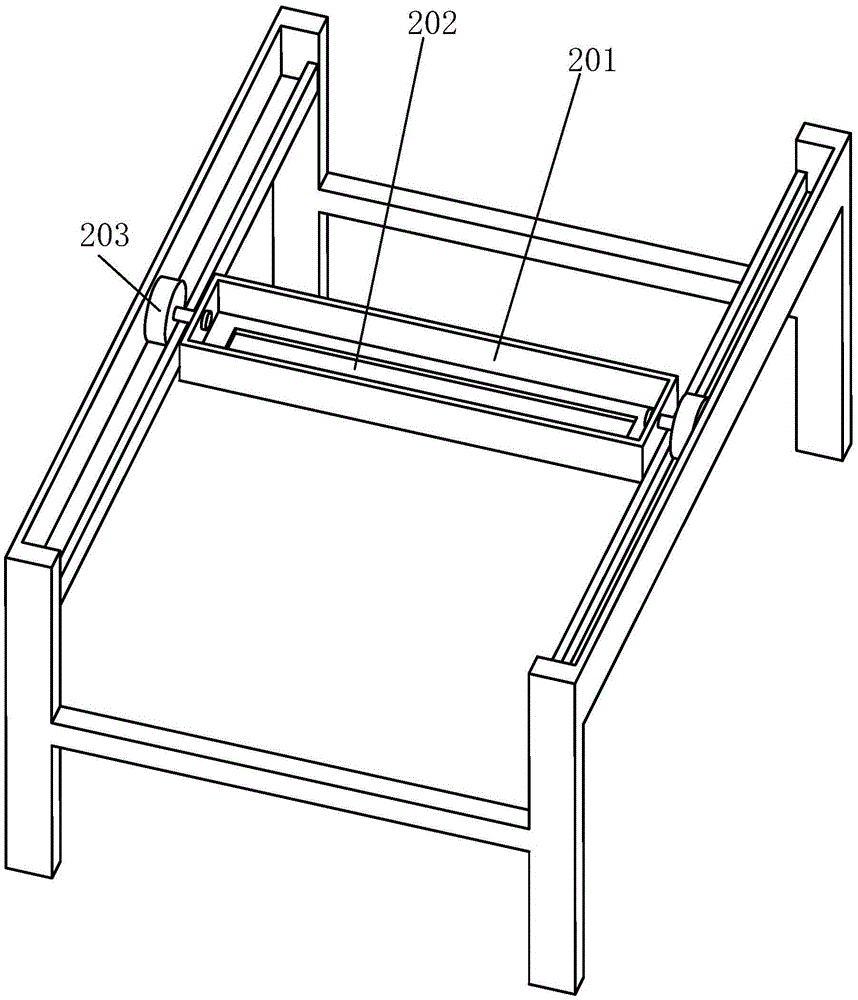

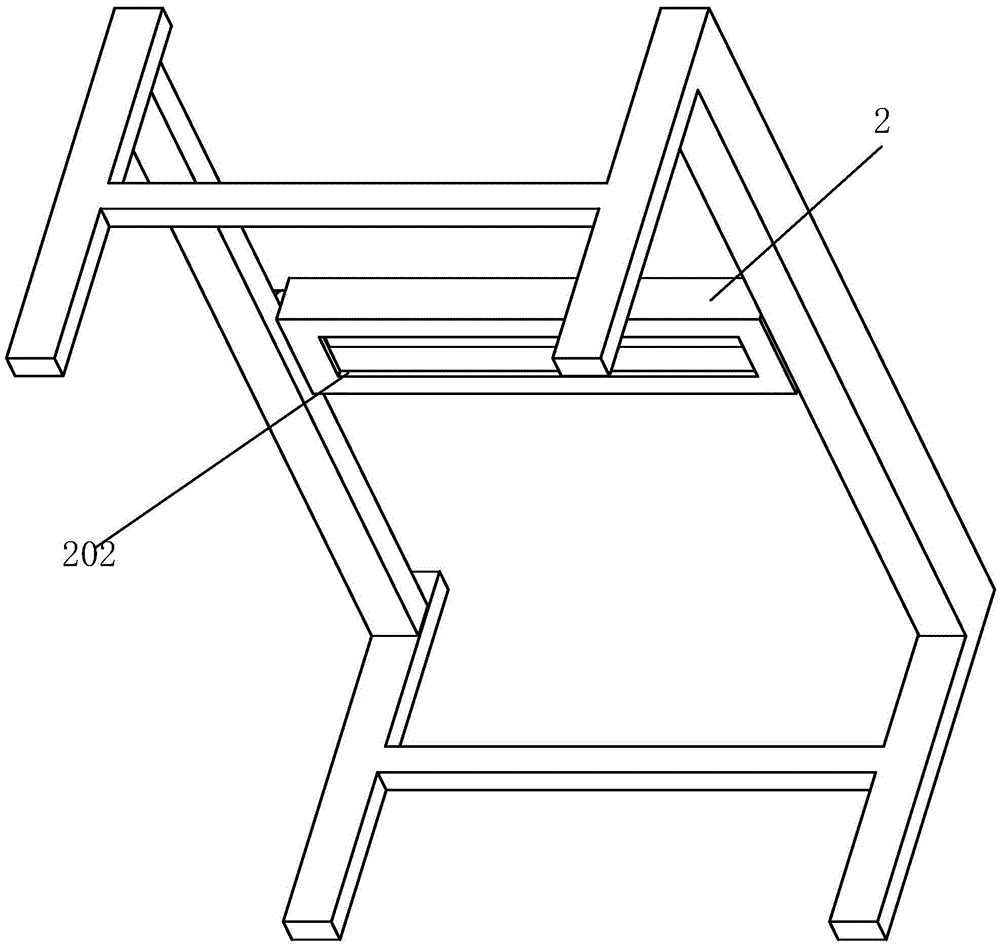

[0019] Such as Figure 1 to Figure 5 As shown, a vertical storage and clamping frame for thin plate parts includes a main frame 1, a sliding frame 2 and a clamping plate frame 3.

[0020] Each of the left and right ends of the main frame 1 is provided with a slideway 101.

[0021] The upper end surface of the sliding frame 2 is provided with a rectangular groove 201, the center of the lower end surface of the rectangular groove 201 is provided with a horizontal bar-shaped hole 202, and the left end surface and the right end surface of the sliding frame 2 are each installed with one The rollers 203 respectively located in the slideway 101 on the corresponding side can roll back and forth in the slideway 101 on the corresponding side.

[0022] The clamping plate frame 3 includes a vertical plate 4, a side wheel 5 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com