Combined powder sieving machine

A screening machine and combined technology, applied in the direction of sieve, solid separation, removal of smoke and dust, etc., can solve the problem of high energy consumption, improve the screening capacity, solve the problem of dust, and prevent the effect of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

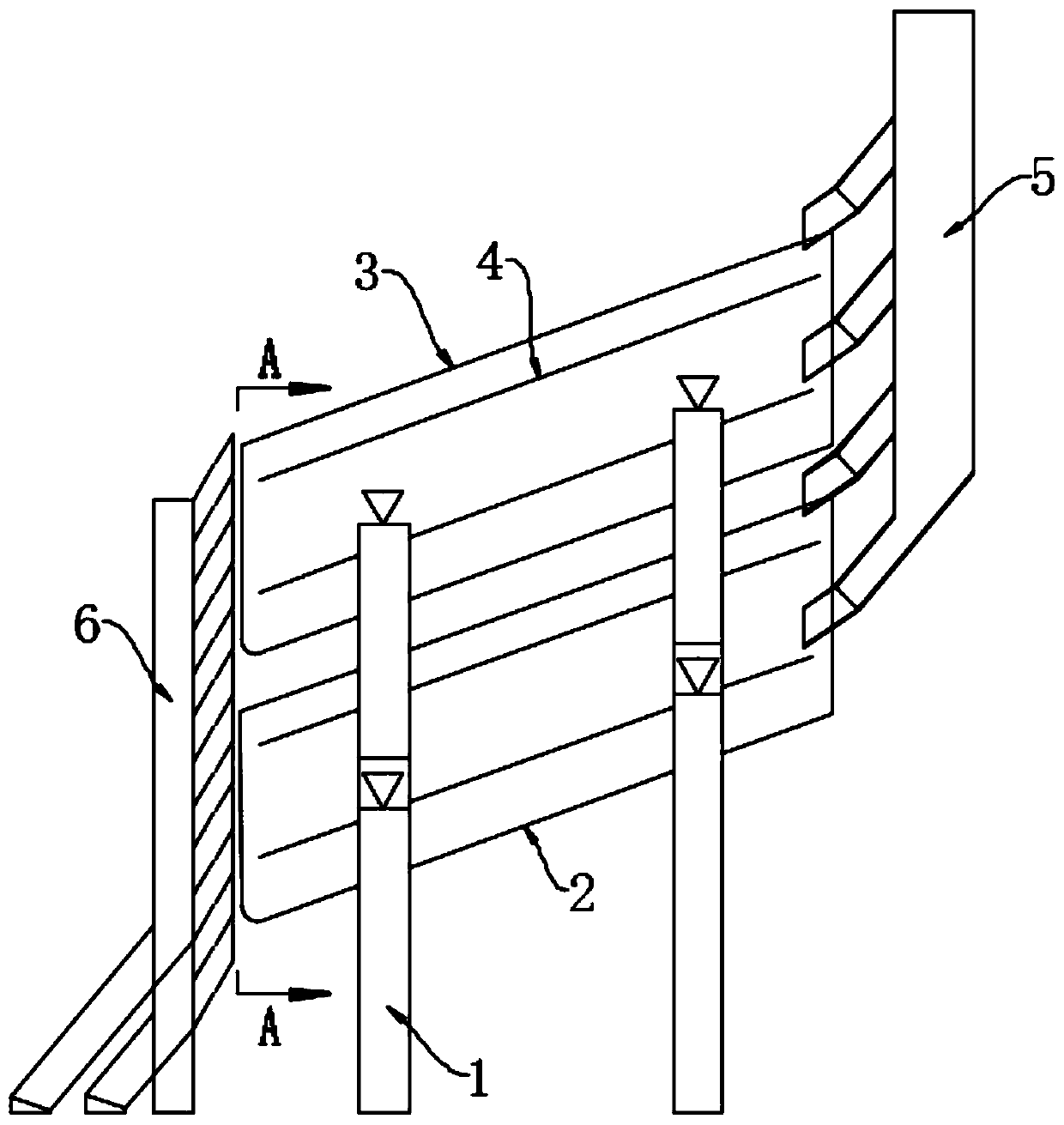

[0024] see Figure 1~2 , in an embodiment of the present invention, a combined powder screening machine includes a sieve body support column 1, a lower sieve body 2 and an upper sieve body 3 are fixedly arranged on the sieve body support column 1, and the lower sieve body 2 and the upper sieve body The sieve body 3 is a cuboid structure, the lower sieve body 2 and the upper sieve body 3 are inclined to the left and lower; the upper sieve body 3 is located directly above the lower sieve body 2; the lower sieve body 2 and the upper sieve body 3 There are several layers of sieves 4 inside, the sieves 4 in the lower sieve body 2 gradually decrease from top to bottom, and the sieves 4 in the upper sieve 3 gradually decrease from top to bottom. small, so as to carry out step-by-step screening; through the setting of the multi-layer screen 4, the multi-stage screening inside the upper screen body 3 and the lower screen body 2 is realized, which makes the cement powder screening furth...

Embodiment 2

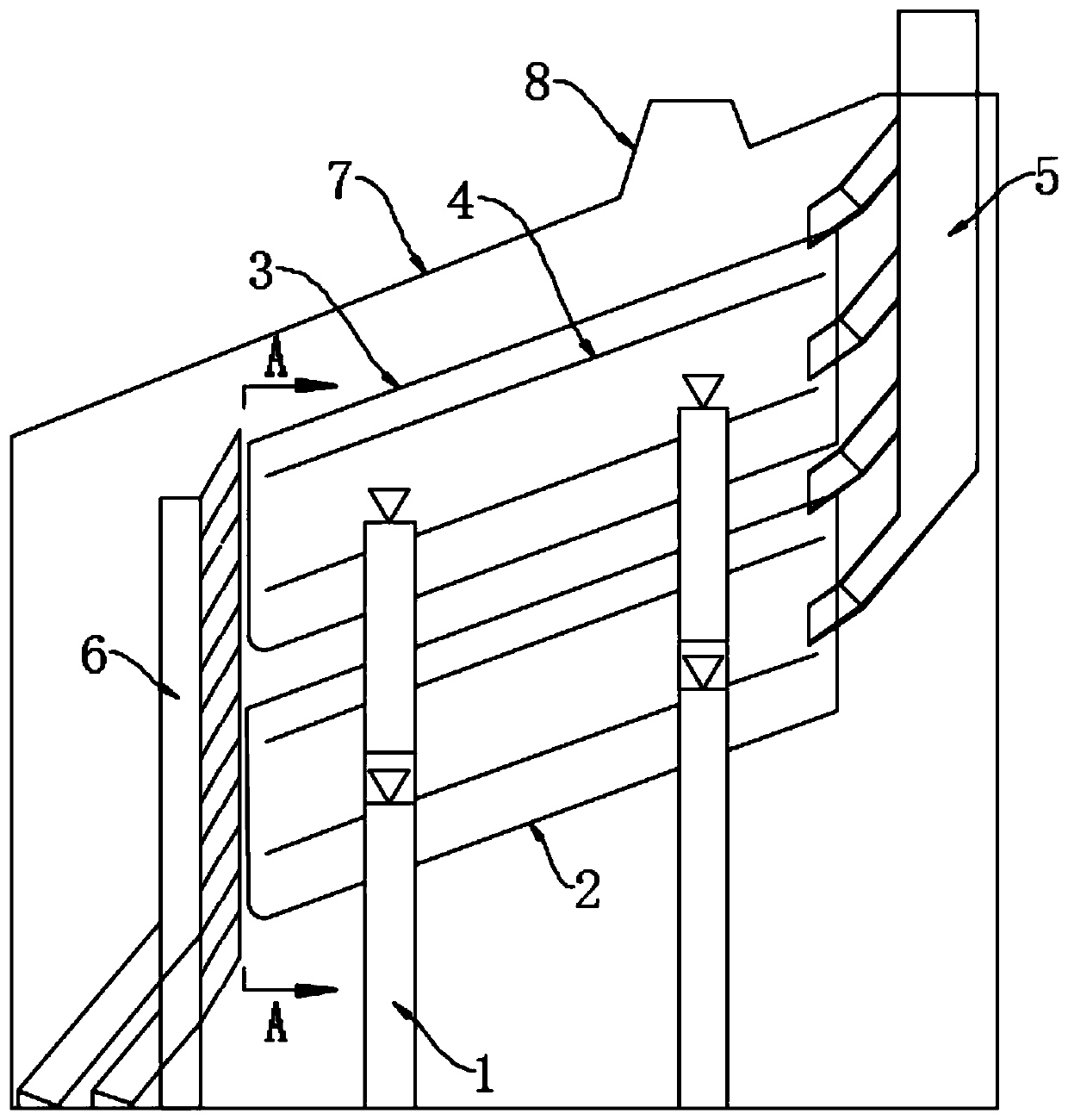

[0028] see image 3 , on the basis of embodiment 1, it also includes an outer casing 7, the upper sieve body 3, the lower sieve body 2, and the distributor 6 are all located in the outer casing 7 to prevent dust from being raised; the feed inlet of the distributor 5 It extends through the outer shell 7 to the outside of the outer shell 7, which is convenient for feeding; the top of the outer shell 7 is provided with a dust collection port 8, and by connecting a vacuum cleaner at the dust collection port 8, the dust is recovered by the vacuum cleaner, which completely solves the problem of vibrating screen dust problem, more environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com