A water treatment air flotation pool

An air flotation tank and water treatment technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problem of low water treatment efficiency in air flotation tank, achieve good effect and improve collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

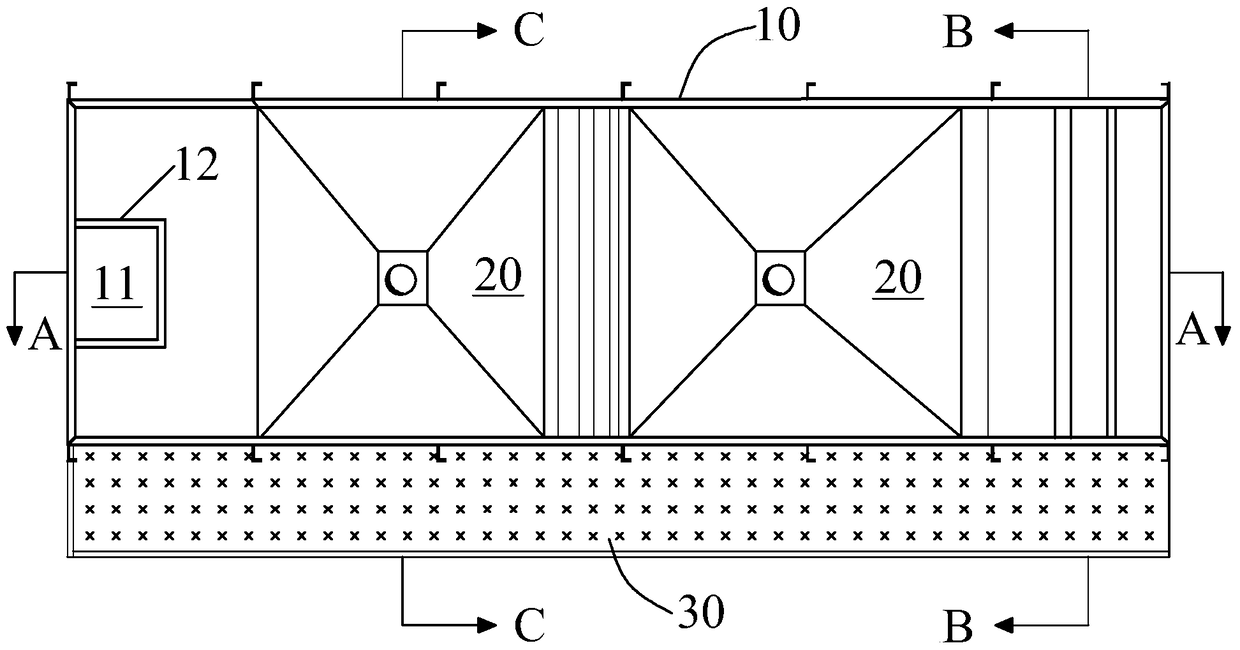

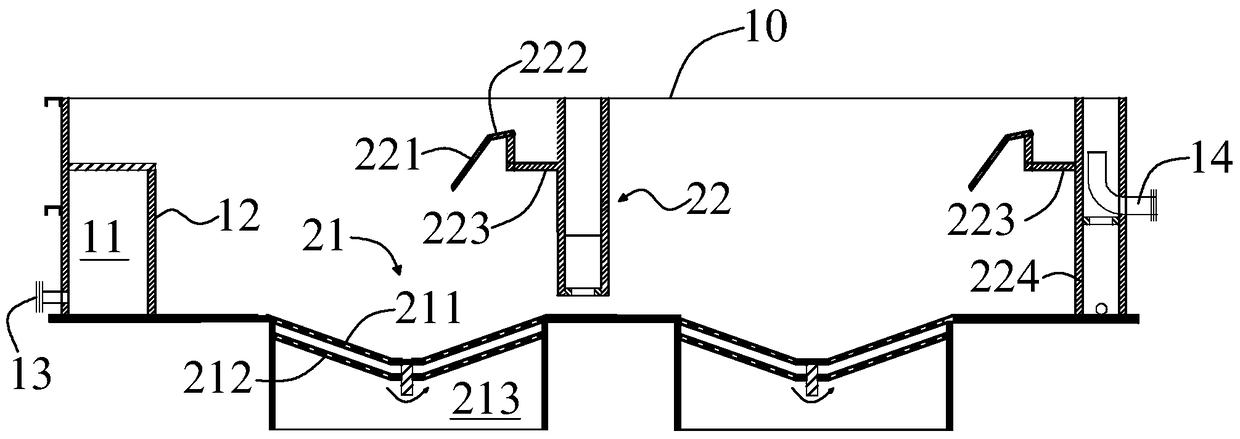

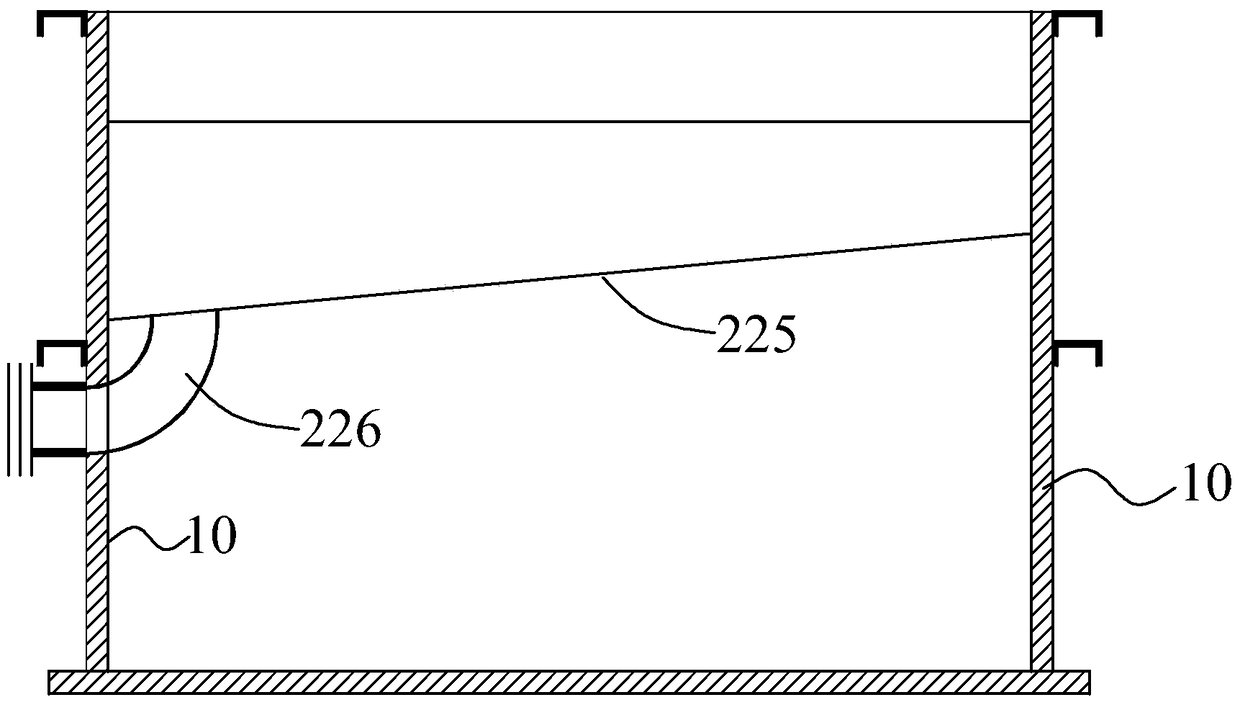

[0028] see figure 1 , figure 1 It is a top view of an embodiment of the air flotation pool of the present invention. exist figure 1 In the illustrated embodiment, a kind of high-efficiency water treatment air flotation pool of this structure includes a pool body 10, and one end in the pool body 10 is provided with a water inlet chamber 11 surrounded by a water inlet partition 12 and a pool wall. The water inlet chamber 11 communicates with the water inlet pipe 13 . In the pool body 10, several processing units 20 are arranged in the pool body 10, and the processing units 20 include a slagging part 22 arranged at the sedimentation part 21 and the end of the sedimentation part 21. The sedimentation part The part 21 is provided in the pool body 10 through a detachable structure. After the sewage enters the water inlet chamber 11 from the water inlet pipe 13 , it flows to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com