Yarn cooling device

A cooling device and yarn technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of cooling air flow fluctuation, easy generation of eddy current, and easy difference in yarn quality, etc., to achieve the purpose of suppressing cooling Effects of difference in air flow rate, suppression of uneven cooling, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the yarn cooling device of the present invention will be described below.

[0029] [Melt spinning device]

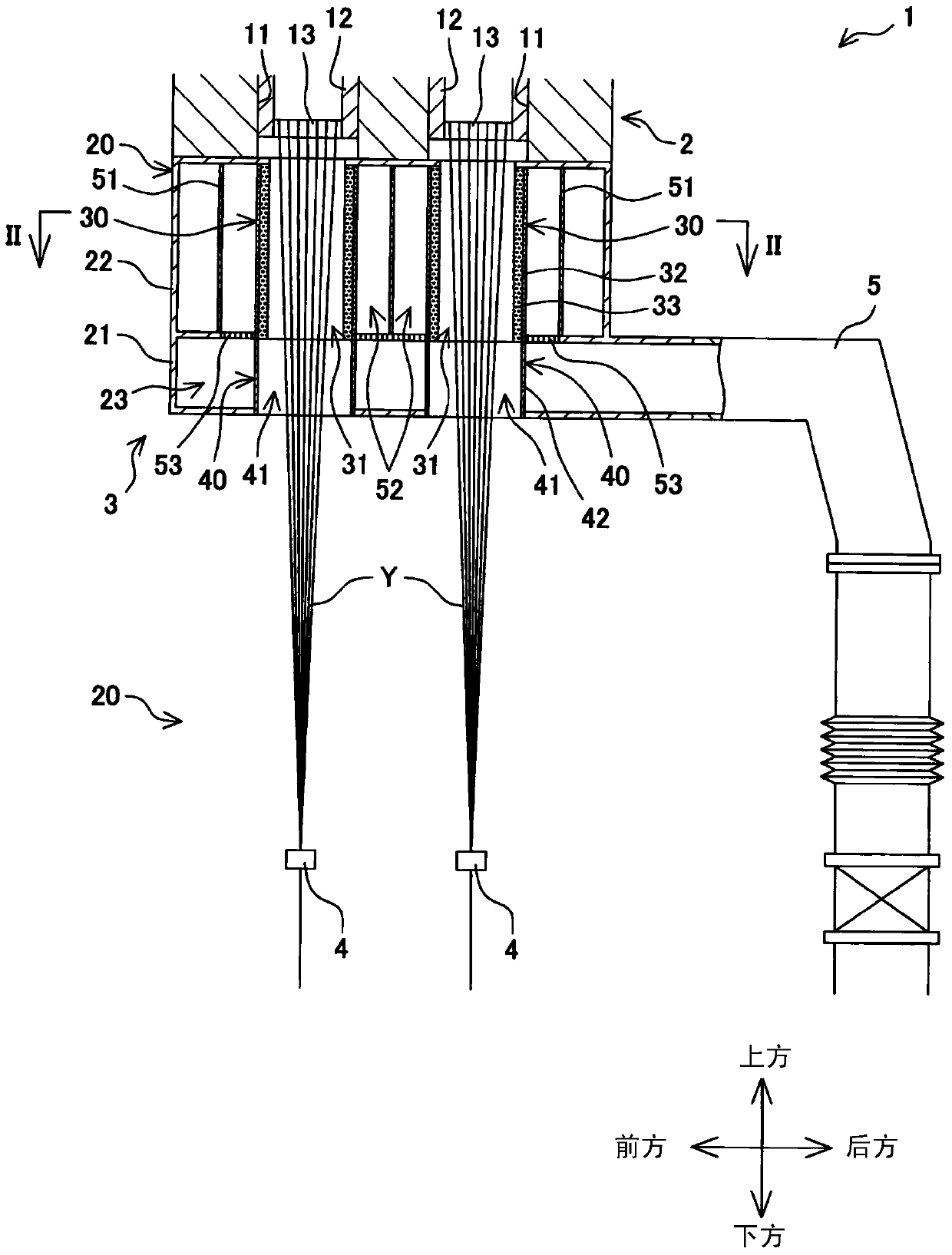

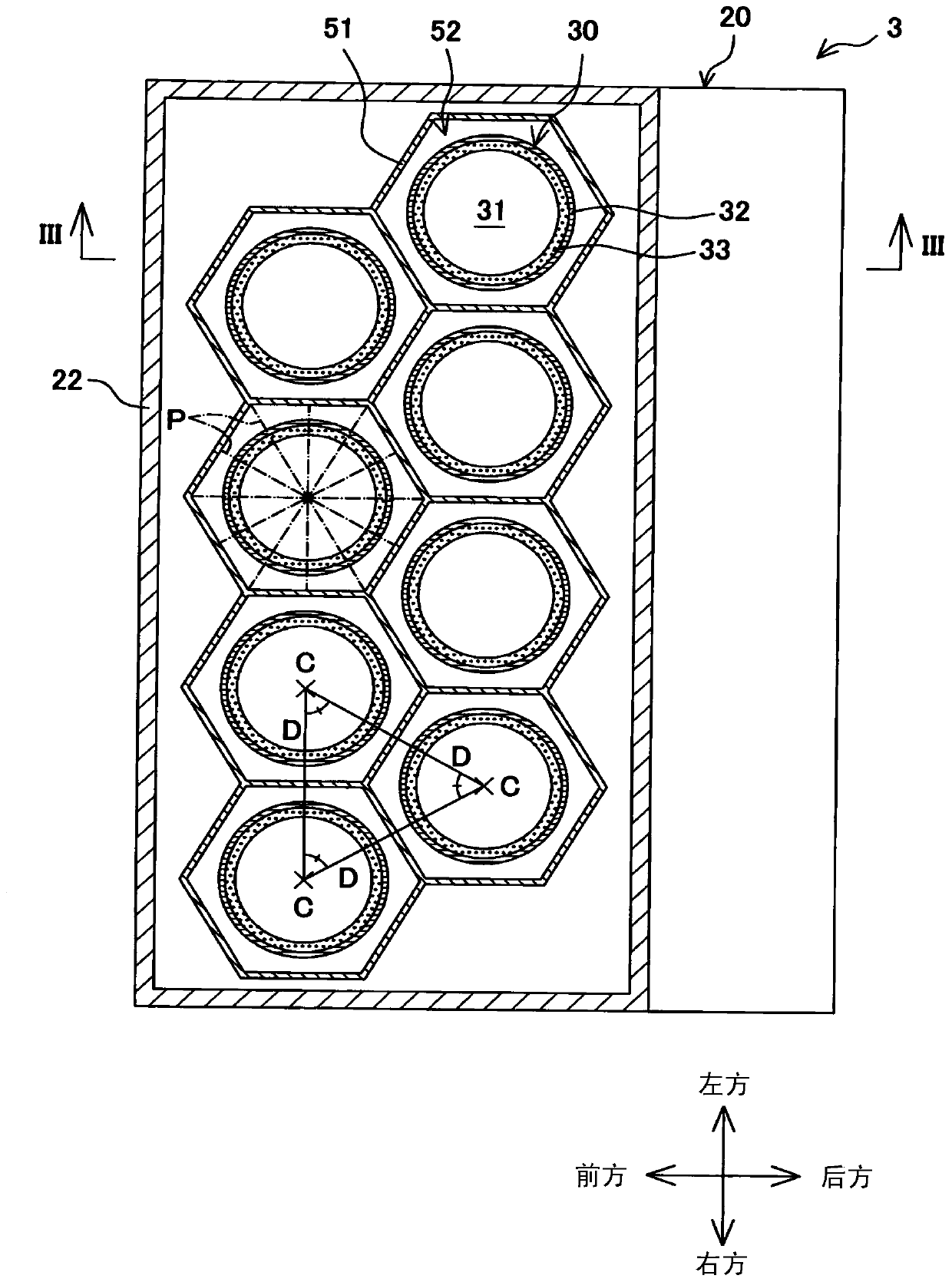

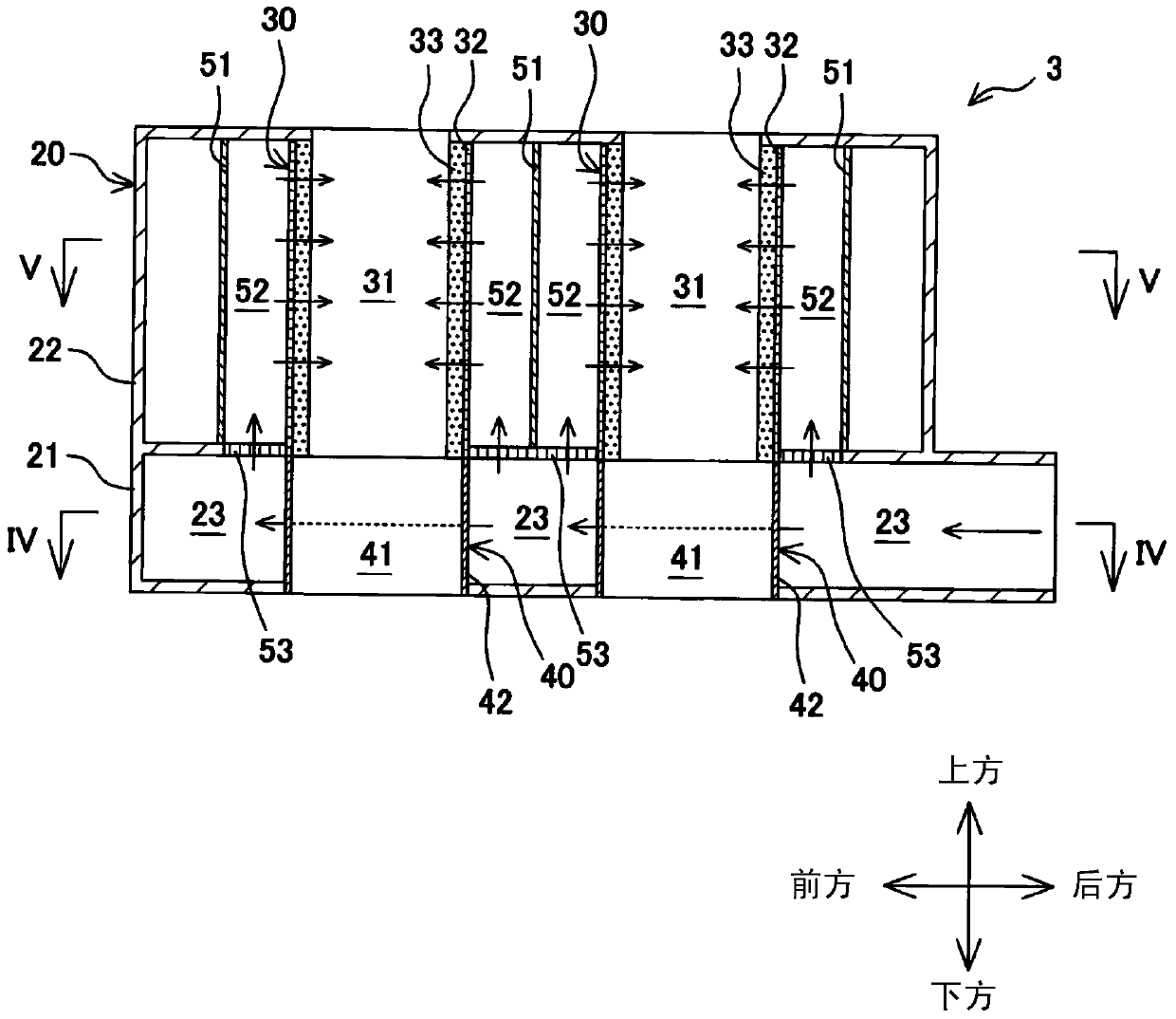

[0030] figure 1 It is a partial sectional view of a melt spinning device equipped with the yarn cooling device of the present invention. Such as figure 1 As shown, the melt spinning device 1 includes a spinning beam 2, a yarn cooling device 3, an oil feeding device 4, and the like. The spinning beam 2 includes a plurality of unit housings 11 . The spin pack 12 is arranged in each pack case 11, and the melted material that becomes the yarn Y such as molten polyester is stored in the spin pack 12. A spinneret 13 is provided at the lower end of the spinneret 12, and the molten material stored in the spinneret 12 is formed as a plurality of yarns Y from a plurality of through holes not shown in the spinneret 13. Spun out to the bottom. Among them, the plurality of spinnerets 13 are arranged in two rows in a staggered manner along the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com