A Productivity Prediction Method for Gas Test Wells

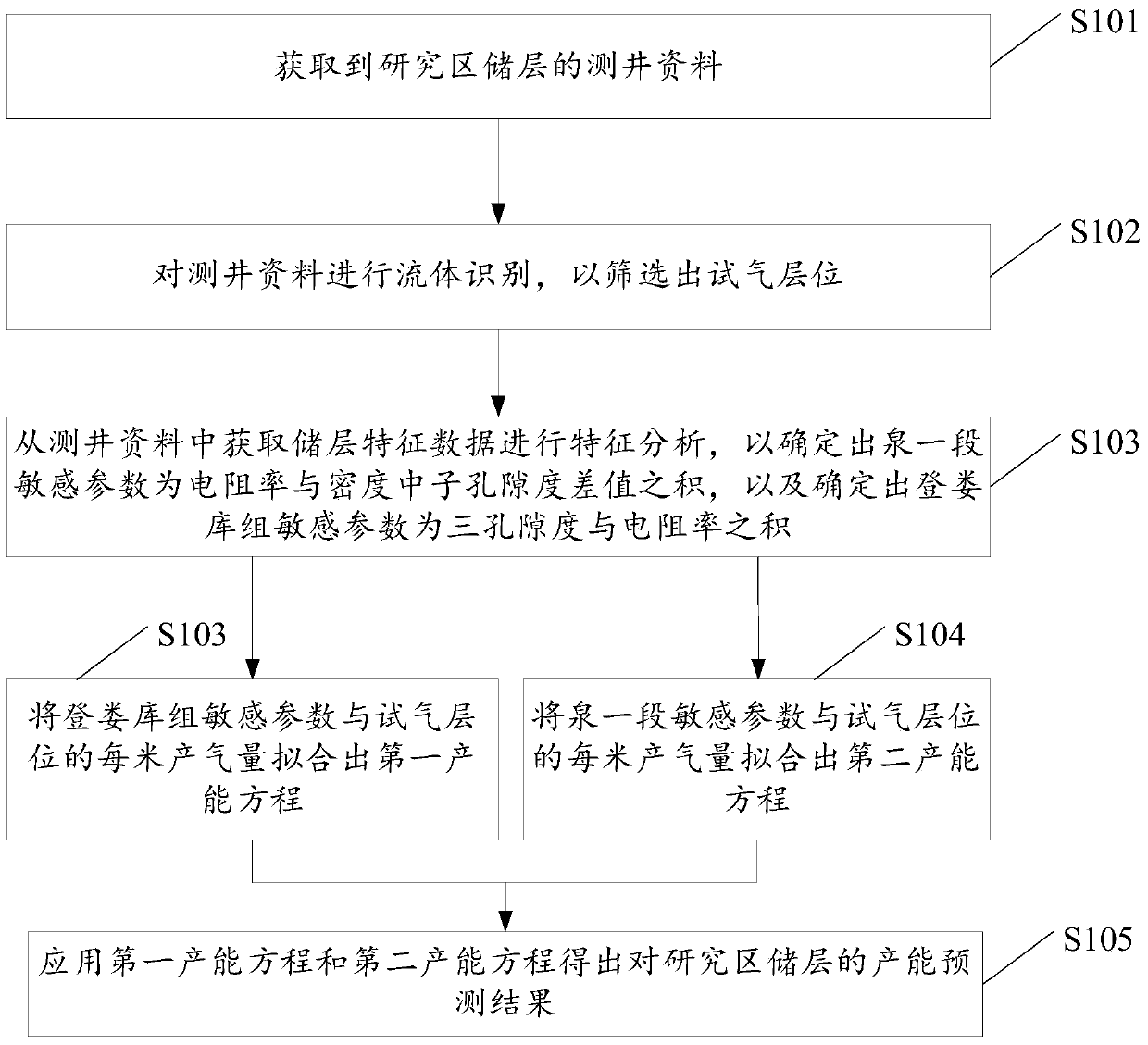

A prediction method and productivity prediction technology, applied in prediction, earthwork drilling and production, wellbore/well components, etc., can solve the problem of lack of available information acquisition of optimal reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] Specifically, there are at least the following two implementations for the calculation of gas production per meter, which will be described separately below:

Embodiment approach 1

[0046] Embodiment 1: Carry out the calculation of gas production per meter in groups and sections, specifically the following steps in sequence:

[0047] Step 1: Calculate the cumulative permeability curve of each gas test well by using well logging data.

[0048] Step 2: According to the cumulative permeability curve, take the contribution amount greater than the preset percentage as the effective layer thickness of the gas test layer. For example, use the cumulative permeability curve to take the thickness with a contribution greater than 90% as the effective thickness of the test gas layer. Of course, the specific implementation process can also adjust the preset percentage according to actual needs.

[0049] Step 3: Divide the test gas output of the gas test layer by the effective layer thickness of the gas test layer to obtain the gas production per meter of the gas test layer.

[0050] Specifically, the gas test output is specifically the single-layer gas test output or...

Embodiment approach 2

[0058] Embodiment 2: Carry out the calculation of the gas production per meter in groups and sections as follows:

[0059] Step 1: Estimate the effective layer thickness of the gas test layer according to the intersection of neutron density.

[0060] Step 2: Divide the test gas output of the gas test layer by the effective thickness of the layer to obtain the gas production per meter of the gas test layer. In the specific implementation process, the specific implementation process of step 2 in this embodiment can refer to the detailed description of step 3 in the first embodiment.

[0061] After the above step S103 is performed, step S105 is then performed: fitting the sensitive parameters of Quanyi 1 and the gas production per meter of the gas test layer to obtain a second productivity equation.

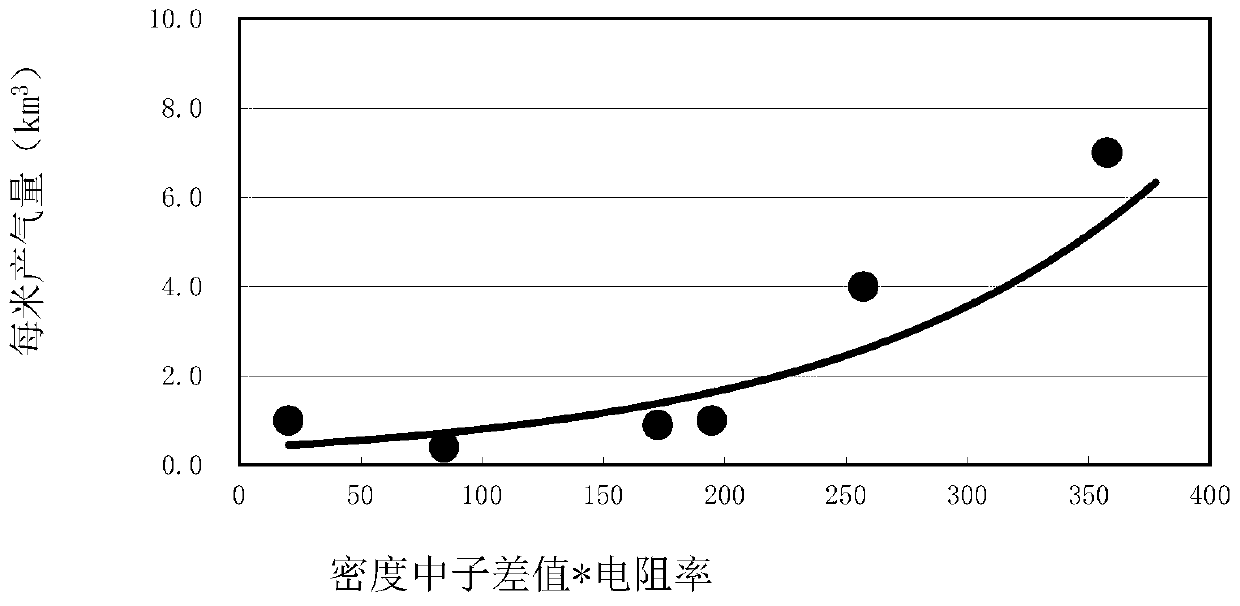

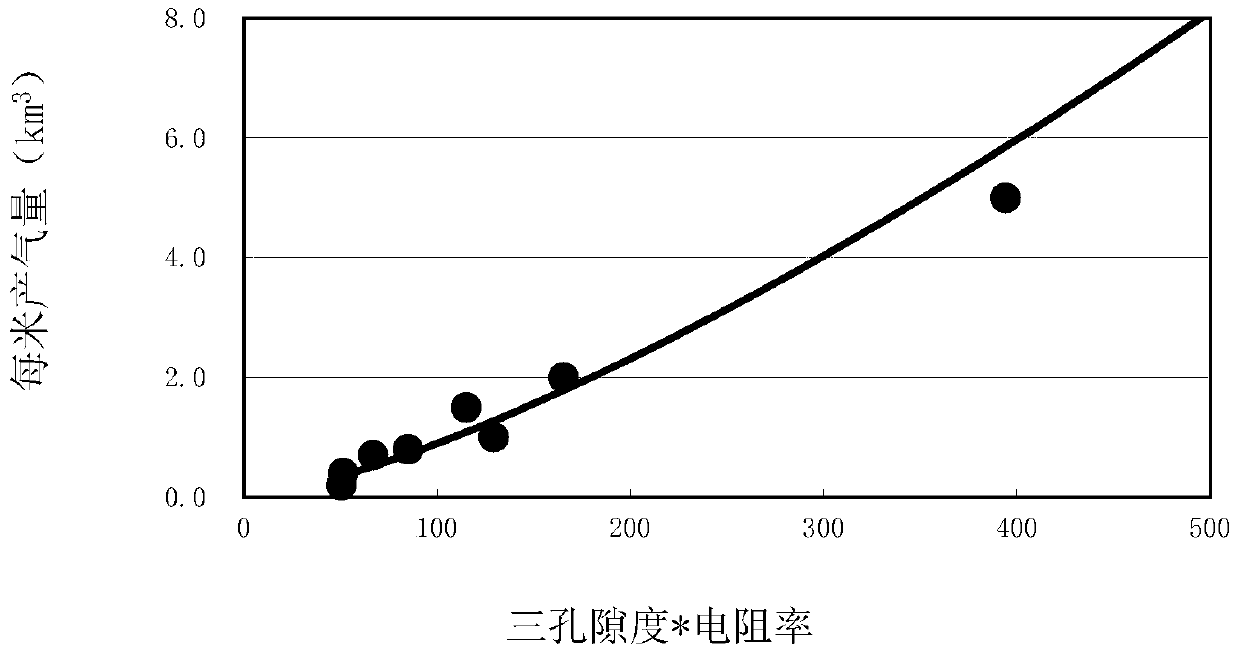

[0062] Specifically, the model reference for fitting the second production capacity equation image 3 Shown, where, y=0.0016x 1.369, R 2 =0.9069, X represents the product of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com