Catenary quick-changing rack of reinforced shot blasting machine

A shot blasting machine and catenary type technology, which is applied in the field of hangers, can solve the problems that the tooling hangers are difficult to meet the strengthening process, the failure rate of the rotary type strengthening shot blasting machine is high, and the failure rate of the catenary type strengthening shot blasting machine is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

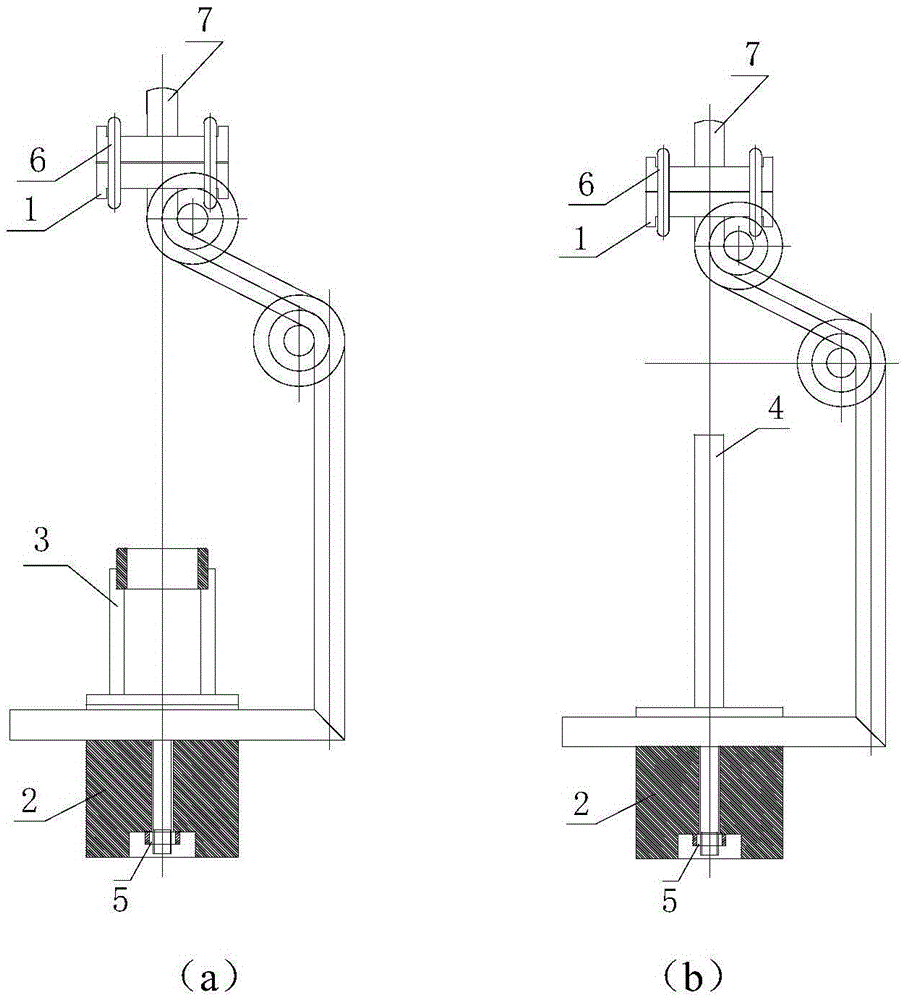

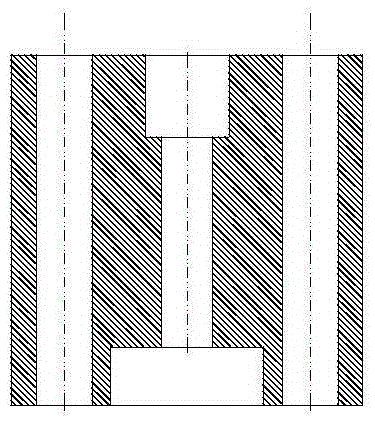

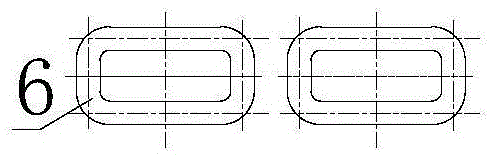

[0029] Such as Figures 1 to 3 As shown, a catenary-type reinforced shot blasting machine quick-change hanger of the present invention includes a curved neck body 1, a weight 2 and a lifting ring 6; wherein, the lifting ring 6 is used to connect the top of the bending neck body 1 to the equipment connecting part 7 The weight 2 is fixed on the bottom of the neck body 1 through the bolts and nuts 5 on the body. The weight 2 is provided with a through hole for inserting the shaft-tooth tooling 3 or the piece-tooth tooling 4. When working, The heavy hammer 2 is provided with a shaft-tooth tooling 3 or a piece-tooth tooling 4, and the parts to be shot blasted are set on the shaft-tooth tooling 3 or the piece-tooth tooling 4. The connection between the lifting ring 6 and the top of the neck body 1 and the center of gravity of the shaft tooth tooling 3 and the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com