Squeeze roller device

A technology of squeezing rollers and transmission devices, applied in the direction of cells, electrolysis process, circuits, etc., can solve the problems of losing the liquid blocking function, unable to ensure the normal liquid level of the electroplating tank, affecting the effect of synchronous transmission, etc., so as to avoid pulling damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

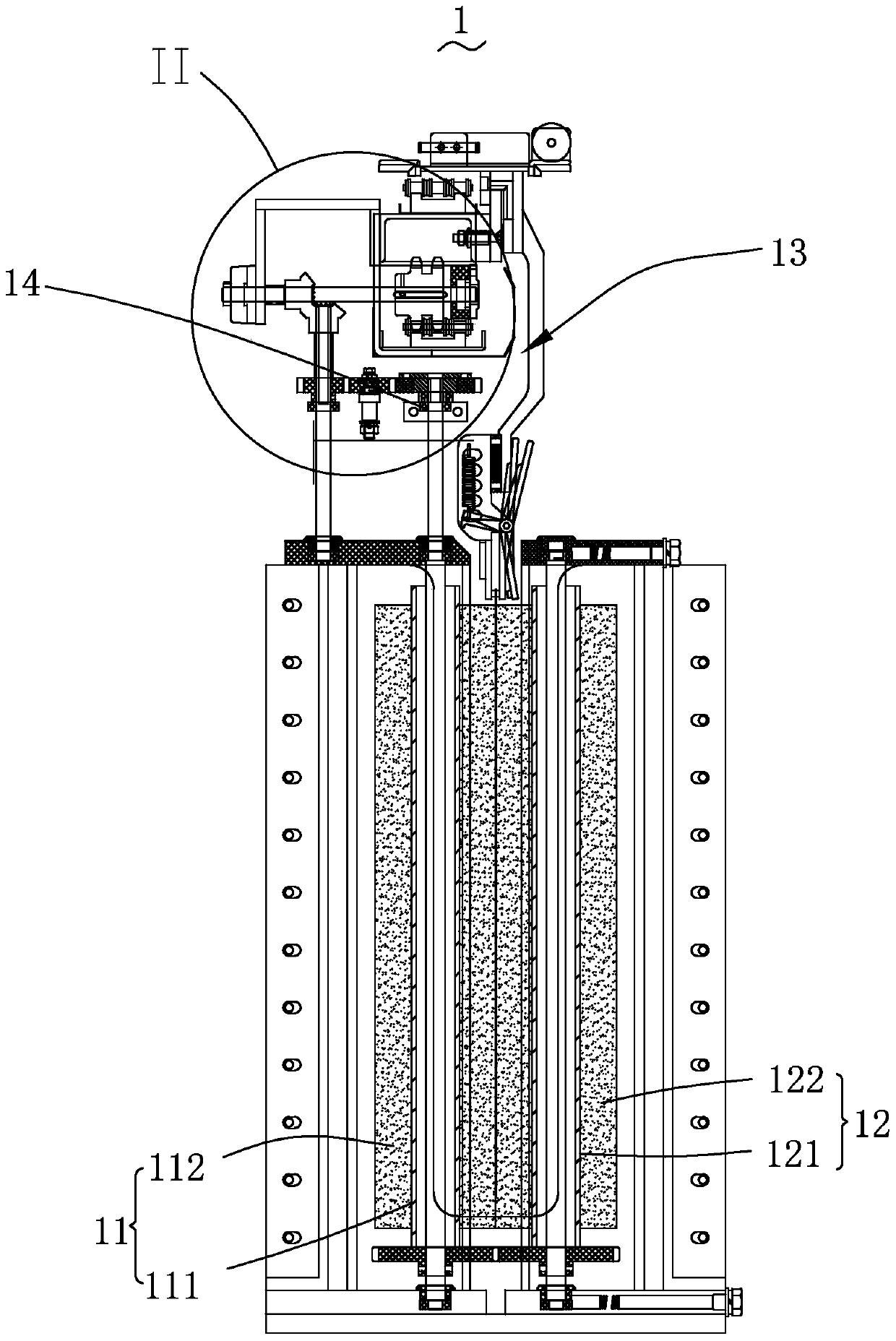

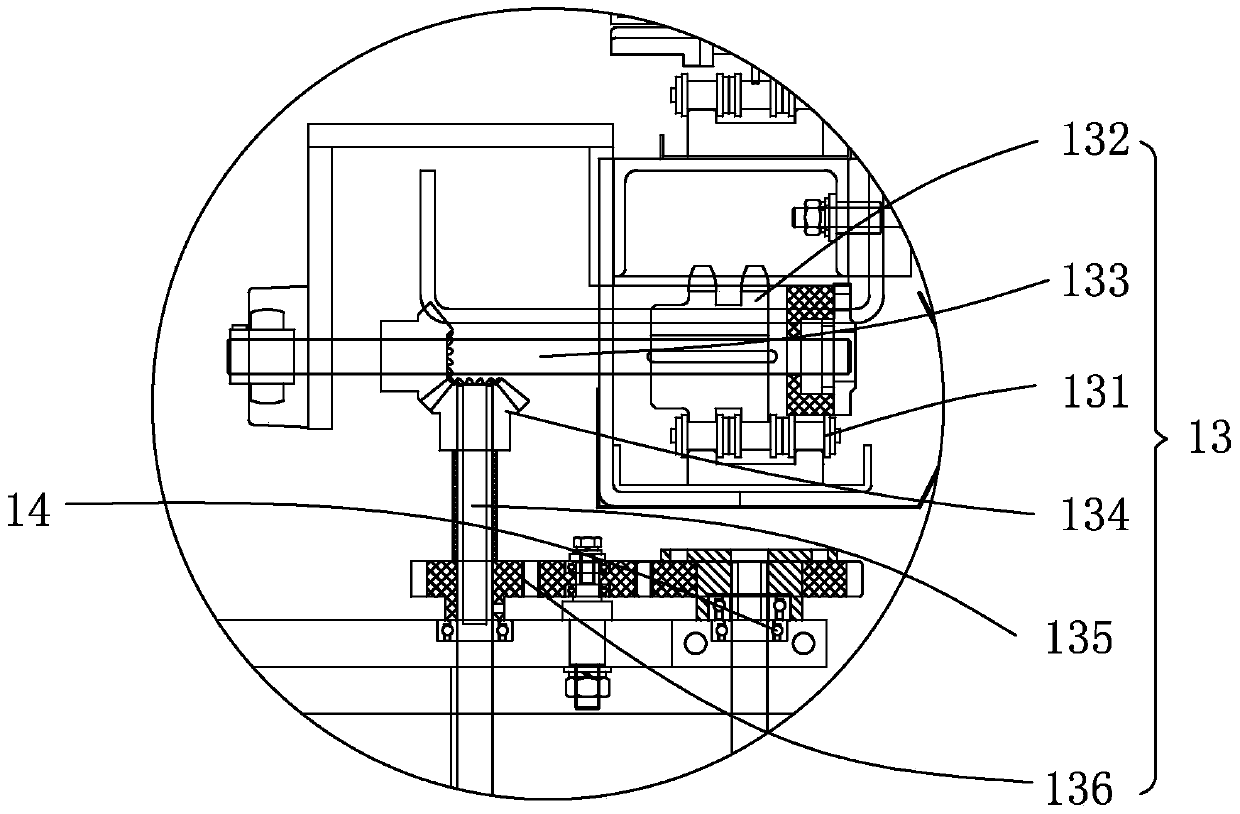

[0016] Please also see figure 1 and figure 2 , wherein, 1 is a schematic structural view of the squeeze roller device of the present invention, figure 2 Yes figure 1 Enlarged view of area II of the squeeze roll arrangement shown. The squeeze roller device 1 includes a first squeeze roller 11 , a second squeeze roller 12 , a transmission device 13 and a one-way bearing 14 . The first squeeze roll 11 and the second squeeze roll 12 are arranged in parallel and juxtaposed.

[0017] The one-way bearing 14 is sheathed on the end of the first squeeze roller 11 and is connected with the transmission device 13. The transmission device 13 drives the first squeeze roller 11 to rotate, and the first squeeze roller 11 rotates. The rotation of a squeeze roller 11 drives the second squeeze roller 12 to rotate relatively.

[0018] The first squeezing roller 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com