Prefabricated shear wall vertical joint connecting structure and construction method thereof

A connection structure and prefabricated assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of long construction period, complex assembly and construction of shear walls, and difficult quality assurance, etc., achieve low cost, improve connection integrity, The effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

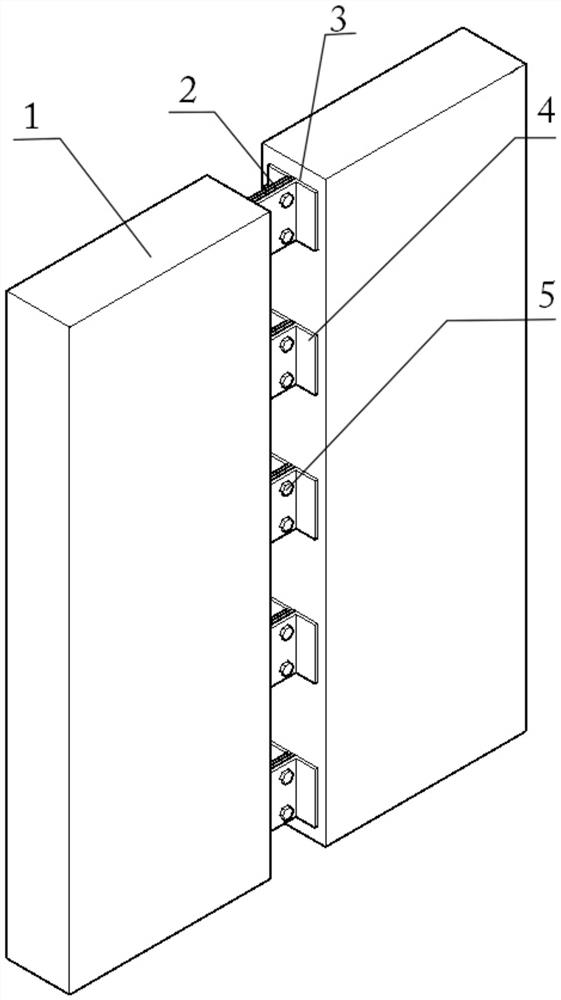

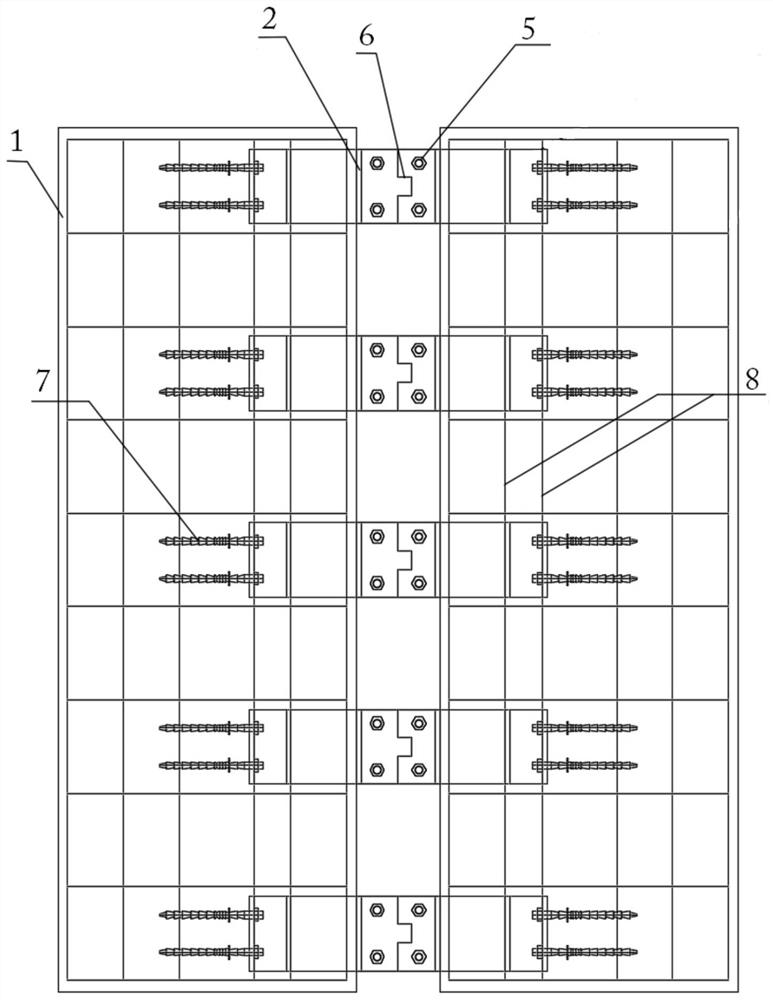

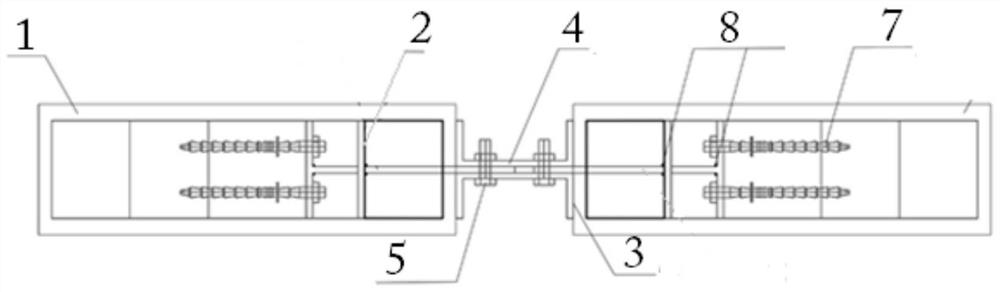

[0030] Such as figure 1 , figure 2 , image 3 As shown, a prefabricated shear wall vertical joint connection structure provided by the present invention includes a shear wall 1, embedded steel 2, connectors 4 and high-strength bolts and bolts 5, and the embedded steel 2 is embedded in the shear wall 1. The pre-embedded section steel 1 includes a web and four flanges on the web, two flanges on both sides of the web, which are symmetrically distributed with reference to the web; a tongue and groove 6 is set at the end parallel to the web, and the two flanges The pre-embedded section steel on the block shear wall is butted through the groove 6, and the two sides of the joint are covered with the connecting piece 4, and the connecting piece 4 and the section steel are fixedly connected with high-strength bolts 5; The FRP composite connector 7 is arranged in the opposite direction of the opening of the mouth 6; the connector 4 is a channel steel, and the two vertically opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com