Waxing device capable of making yarn tightly attached to wax block

A wax block and yarn technology, applied in textiles and papermaking, etc., can solve problems such as yarn breakage, increased pressure on yarn and wax block, poor waxing effect on yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

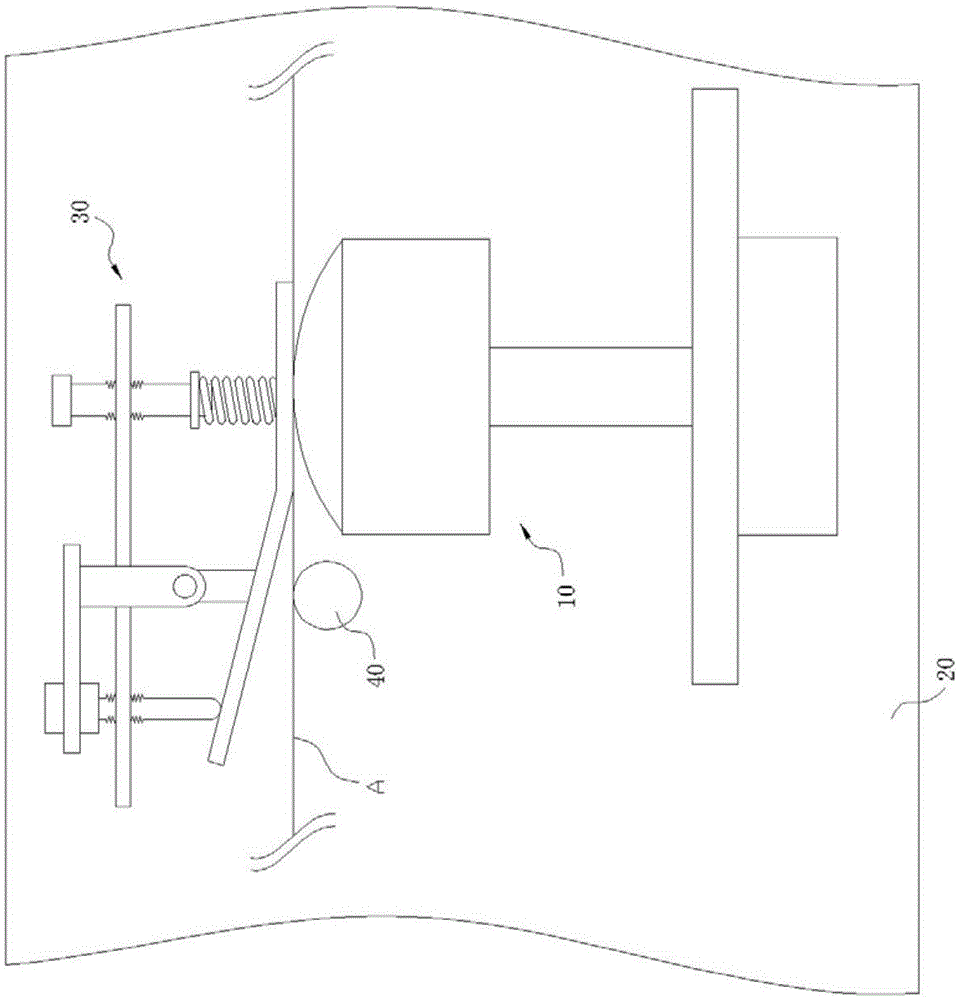

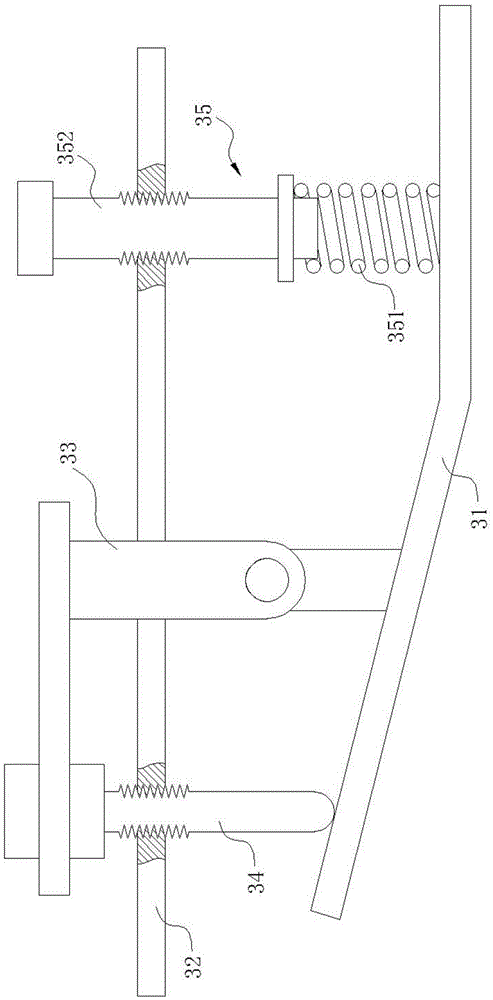

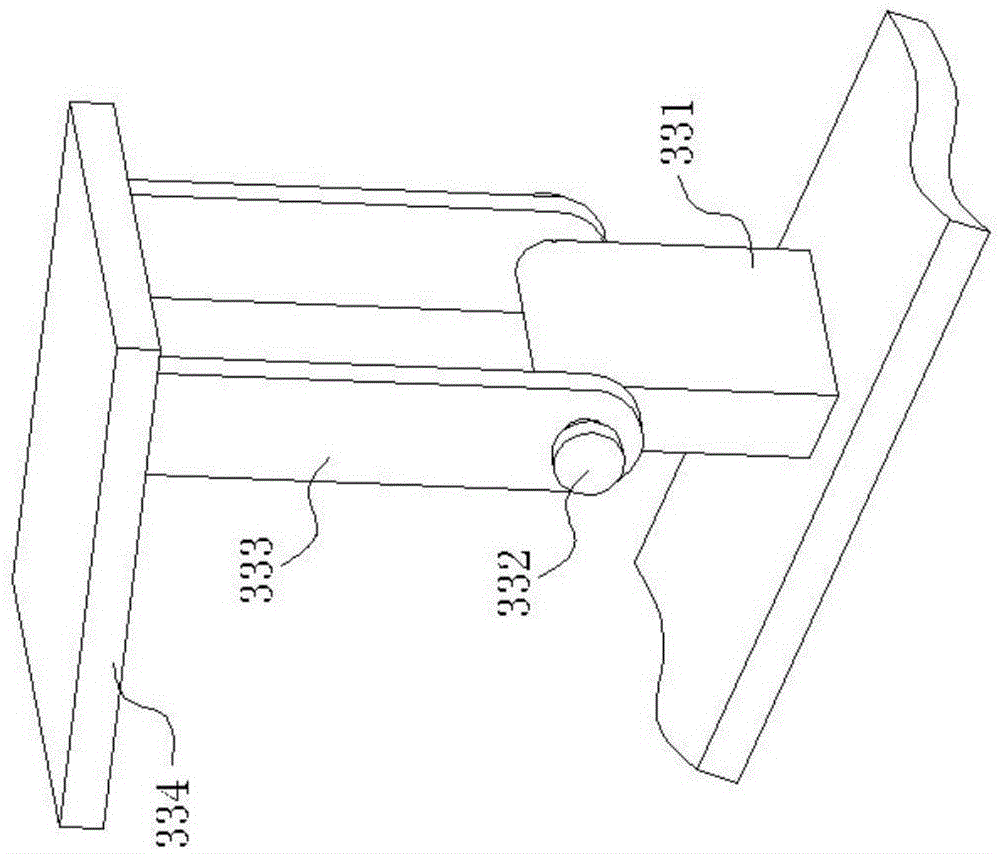

[0020] Such as Figure 1~4 As shown, a waxing device that can make yarns adhere to a wax block includes a waxing machine 10 and a fixed plate 20 for fixing the waxing machine 10, the waxing machine 10 includes a wax block 11, and the wax block 11 is rotated In the transmission device 12, the yarn A passes through the end surface of the wax block 11, and the rotation axis of the wax block 11 is perpendicular to the running direction of the yarn A. It also includes a pressing device 30 fixed on the fixed plate 20. The pressing device 30 includes a V-shaped pressing plate 31 and a base plate 32. The V-shaped pressing plate 31 can press the yarn A on the end surface of the wax block 11. 30 is fixed to the fixed plate 20 through the base plate 32. It also includes a yarn guide wheel 40 which is located on the side of the waxing machine 10 and the yarn guide wheel 40 is located on the side of the yarn A that is not waxed.

[0021] Wherein, the pressing device 30 further includes a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com