Drum washing machine and its foam detection method

The technology of a drum washing machine and a detection method, which is applied in the field of washing machines, can solve the problems of easy leakage of foam in the washing machine, etc., and achieve the effects of obvious water level change frequency, accurate and convenient detection, and preventing the ground from being slippery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

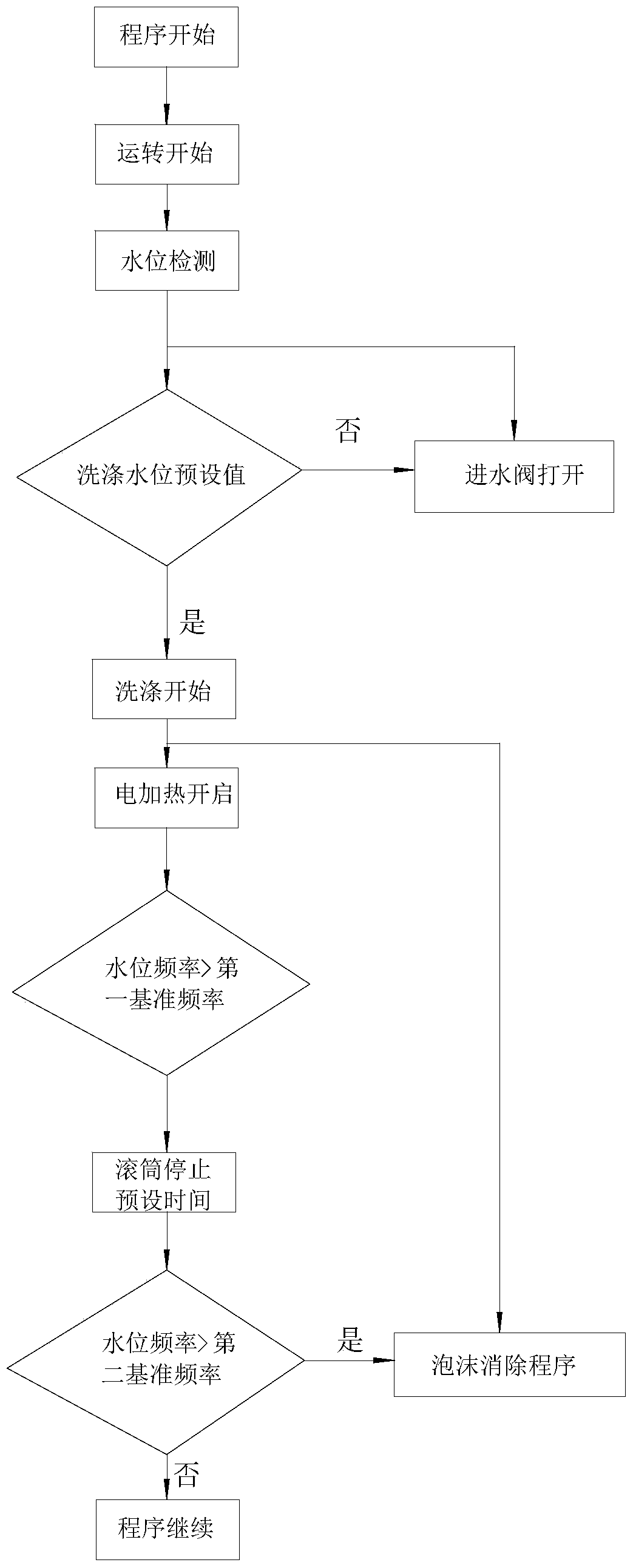

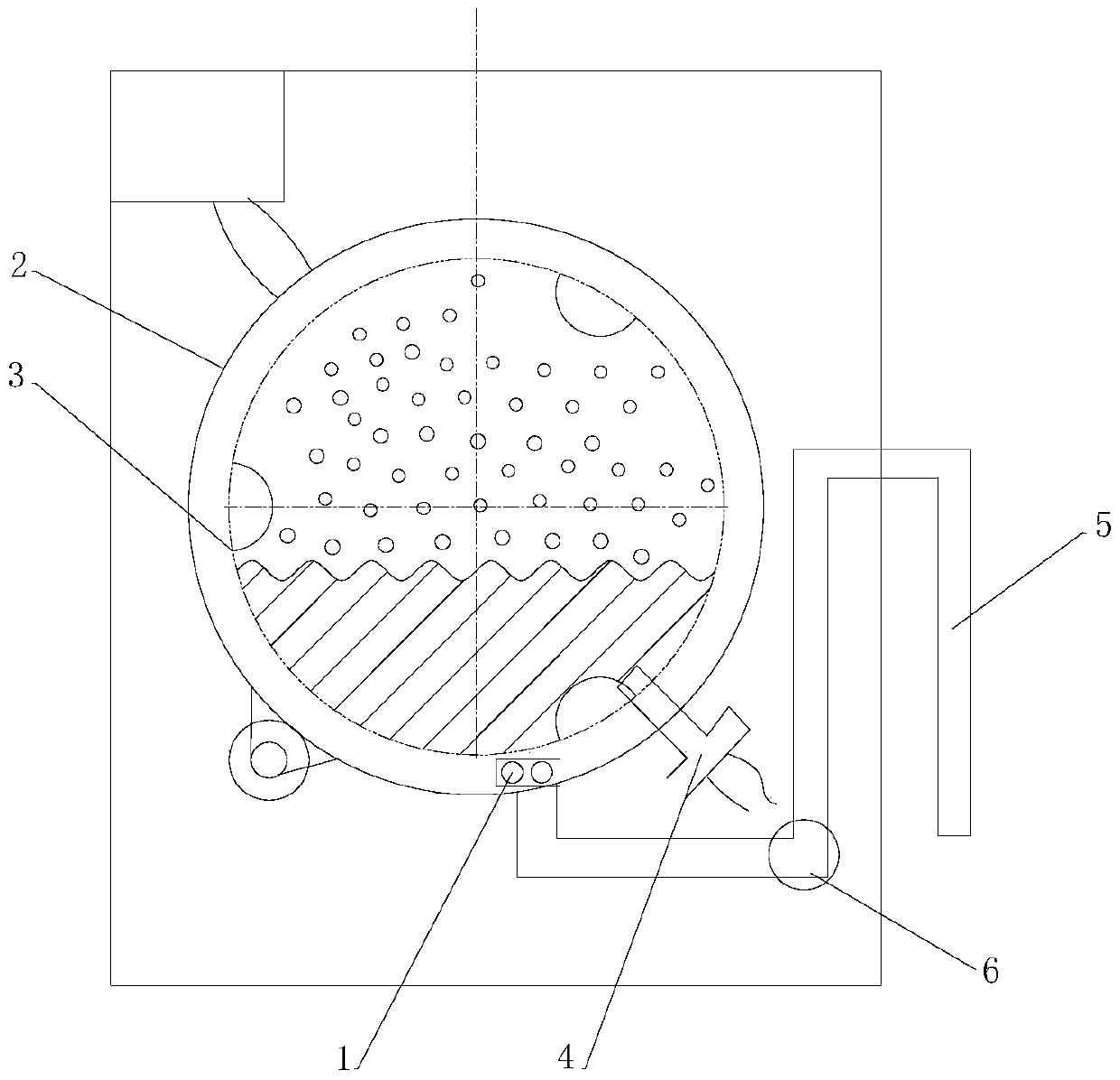

[0019] see in conjunction figure 1 and figure 2 As shown, according to the embodiment of the present invention, the foam detection method of the drum washing machine includes: step S1: enter the washing program; step S2: turn on the electric heater 1 for heating, and detect the frequency of the water level; step S3: convert the detected water level The frequency is compared with the reference frequency of washing, and according to the comparison result, it is judged whether the foam is excessive.

[0020] In the present invention, the water level sensor 4 is combined with the electric heater 1 to judge whether there is excessive foam in the washing cycle, and the heating of the electric heater 1 can be used to accelerate the foam breaking to make the water level change frequency more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com