A kind of antibacterial and anti-felt shrinkage finishing method of wool fabric

A fabric and wool technology, applied in the field of antibacterial and anti-felting finishing, can solve the problems of hard hand feeling, large fabric damage, poor biodegradability, etc., achieve the effect of inhibiting keratinase and improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

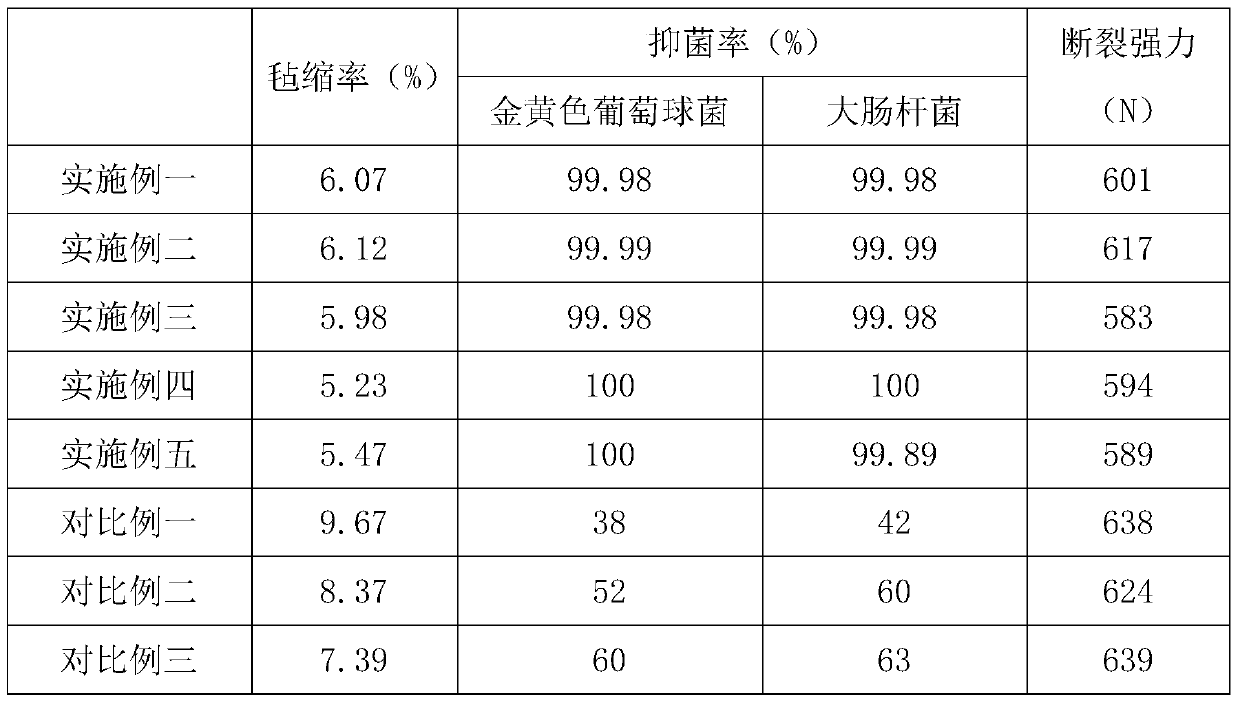

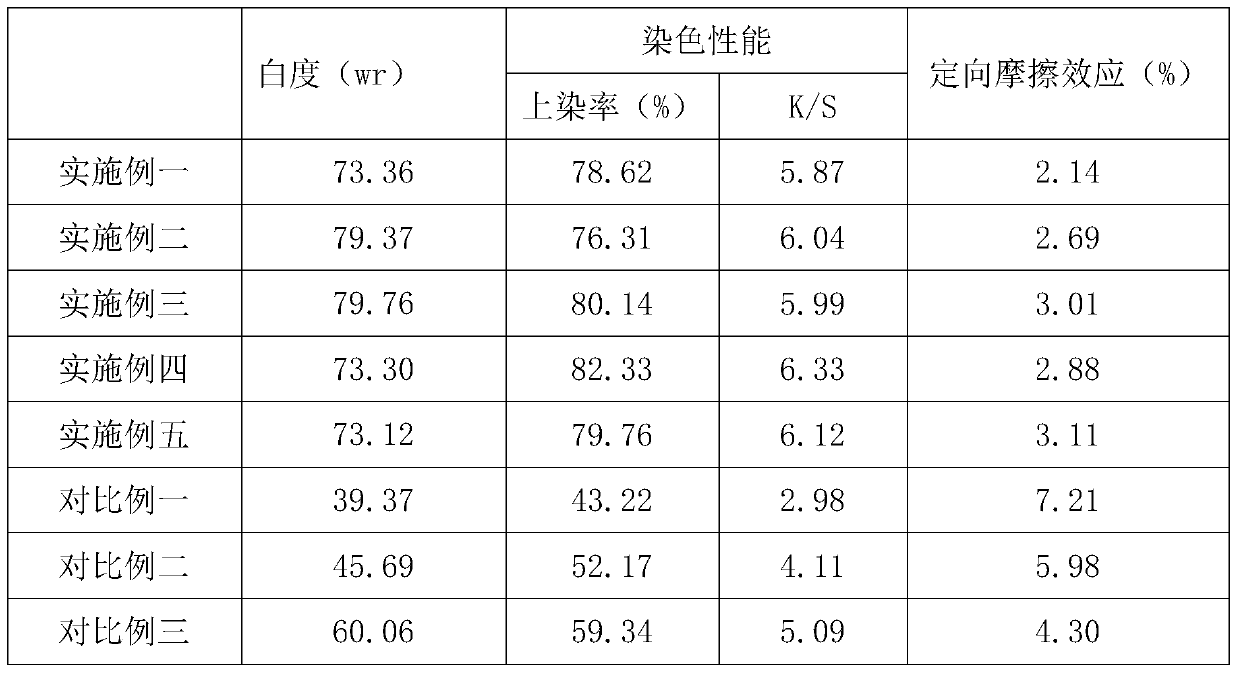

Examples

Embodiment 1

[0046] An antibacterial and anti-felting finishing method for wool fabrics, comprising the following steps:

[0047] The first step: wool fabric hydrogen peroxide pretreatment:

[0048] Processing technology:

[0049] The concentration of hydrogen peroxide is 20%, the amount of sodium hydroxide added is 0.1g / L, the pH value is 7.5, the treatment temperature is 30°C, the treatment time is 20 minutes, and the bath ratio is 1:20;

[0050] Stir and heat to 50°C after treatment;

[0051] The second step: biological enzyme treatment:

[0052] Processing technology:

[0053] Keratinase treatment: the amount of keratinase added is 50U / g wool fabric, the pH value is 8.0, the treatment temperature is 50°C, the treatment time is 20 minutes, and the liquor ratio is 1:30;

[0054] Alkaline protease treatment: the amount of alkaline protease added is 100u / g wool fabric, the pH value is 8.0, the treatment temperature is 60°C, the treatment time is 10 minutes, and the liquor ratio is 1:30...

Embodiment 2

[0062] An antibacterial and anti-felting finishing method for wool fabrics, comprising the following steps:

[0063] The first step: wool fabric hydrogen peroxide pretreatment:

[0064] Processing technology:

[0065] The concentration of hydrogen peroxide is 22%, the amount of sodium hydroxide added is 0.2g / L, the pH value is 8.0, the treatment temperature is 35°C, the treatment time is 30 minutes, and the bath ratio is 1:20;

[0066] Stir and heat to 50°C after treatment;

[0067] The second step: biological enzyme treatment:

[0068] Processing technology:

[0069] Keratinase treatment: the amount of keratinase added is 60U / g wool fabric, the pH value is 8.0, the treatment temperature is 50°C, the treatment time is 25 minutes, and the liquor ratio is 1:30;

[0070] Alkaline protease treatment: the amount of alkaline protease added is 200u / g wool fabric, the pH value is 8.0, the treatment temperature is 60°C, the treatment time is 20 minutes, and the liquor ratio is 1:30...

Embodiment 3

[0078] An antibacterial and anti-felting finishing method for wool fabrics, comprising the following steps:

[0079] The first step: wool fabric hydrogen peroxide pretreatment:

[0080] Processing technology:

[0081] The concentration of hydrogen peroxide is 20%, the amount of sodium hydroxide added is 0.2g / L, the pH value is 7.5, the treatment temperature is 35°C, the treatment time is 20 minutes, and the bath ratio is 1:20;

[0082] Stir and heat to 50°C after treatment;

[0083] The second step: biological enzyme treatment:

[0084] Processing technology:

[0085] Keratinase treatment: the amount of keratinase added is 60U / g wool fabric, the pH value is 8.0, the treatment temperature is 50°C, the treatment time is 20 minutes, and the liquor ratio is 1:30;

[0086] Alkaline protease treatment: the amount of alkaline protease added is 200u / g wool fabric, the pH value is 8.0, the treatment temperature is 60°C, the treatment time is 10 minutes, and the liquor ratio is 1:30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com