Trench-type super junction manufacturing method

A manufacturing method and super-junction technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting production yield, device failure, and device reverse leakage current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

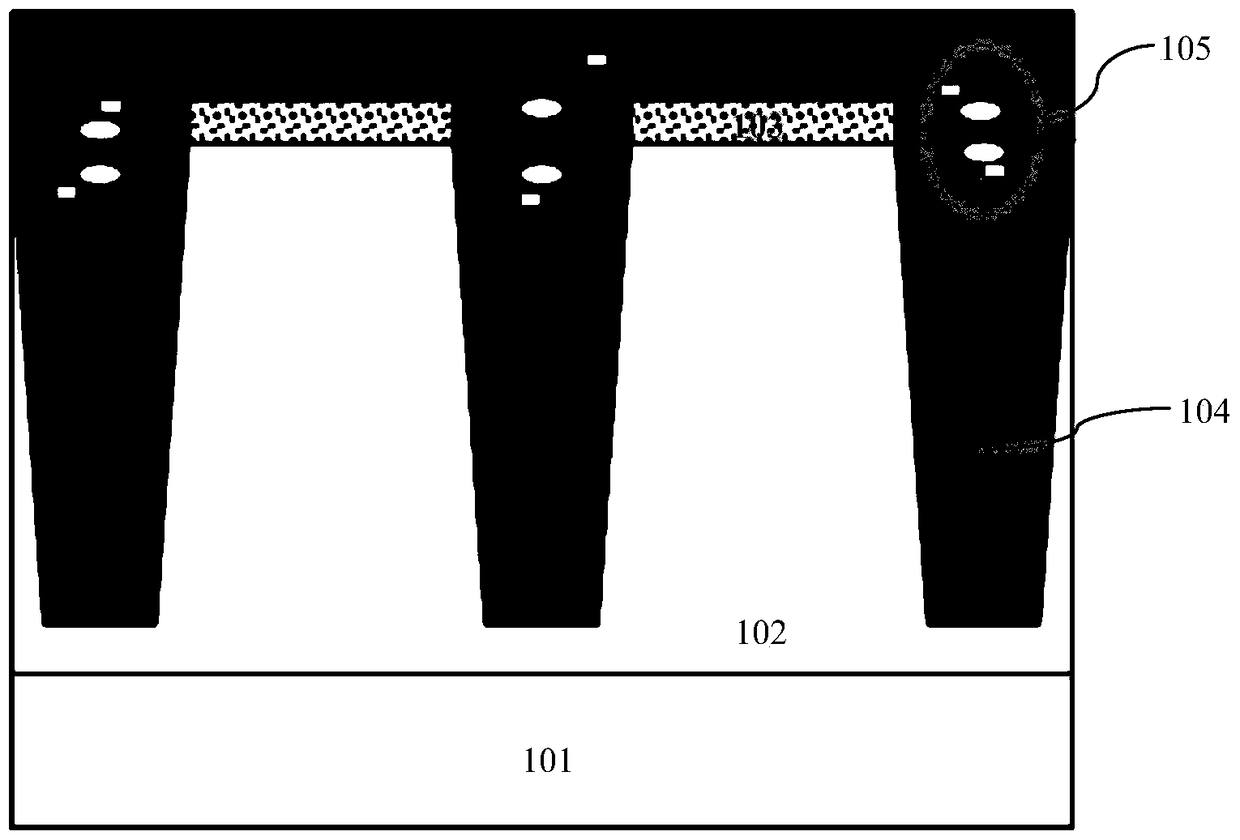

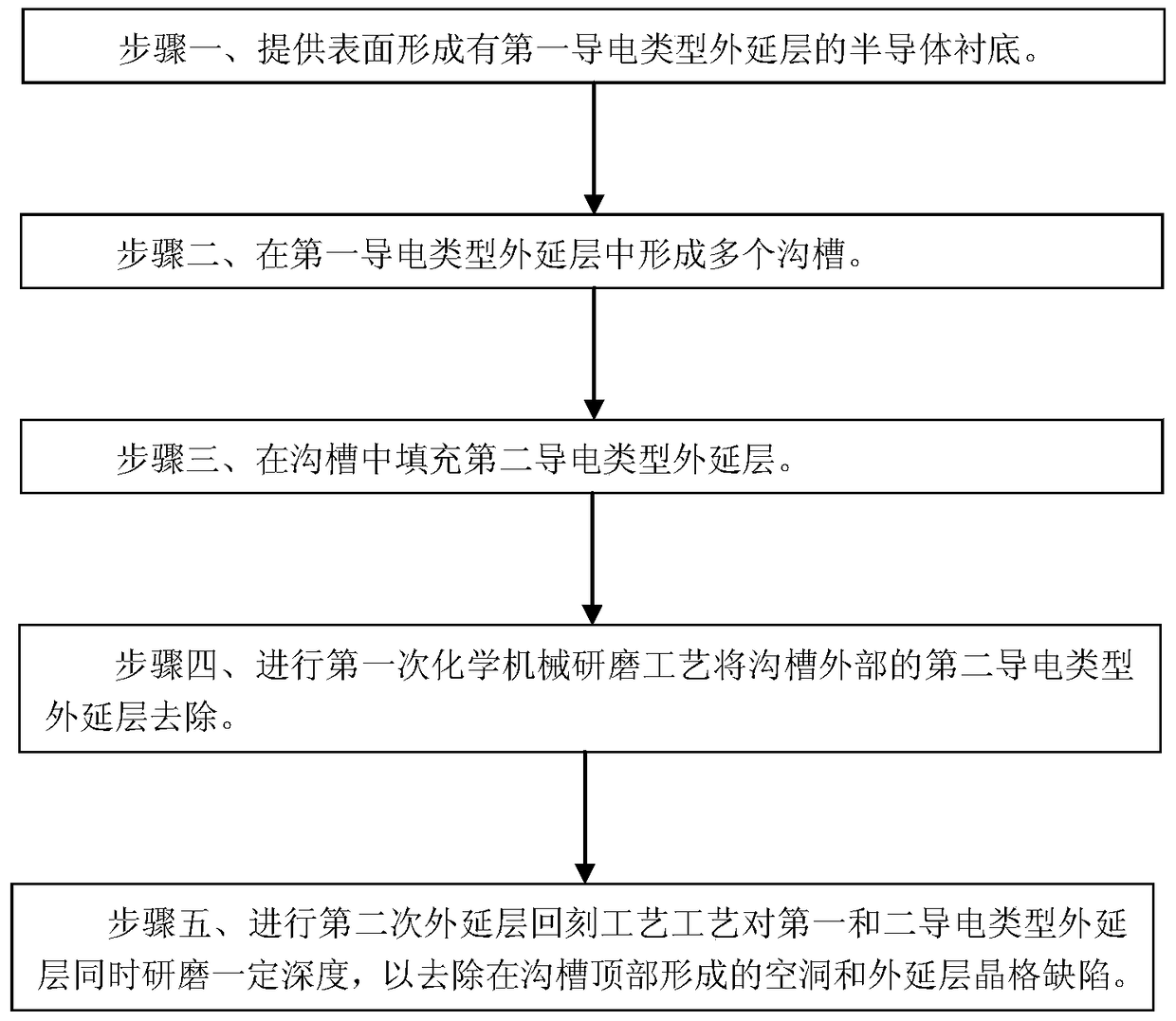

[0037] First introduce the problems of the existing trench superjunction manufacturing method, the present invention has made specific improvements to these technical problems, such as figure 1 Shown is a schematic structural diagram of a super junction formed by an existing trench-type super junction manufacturing method; the existing method includes the following steps:

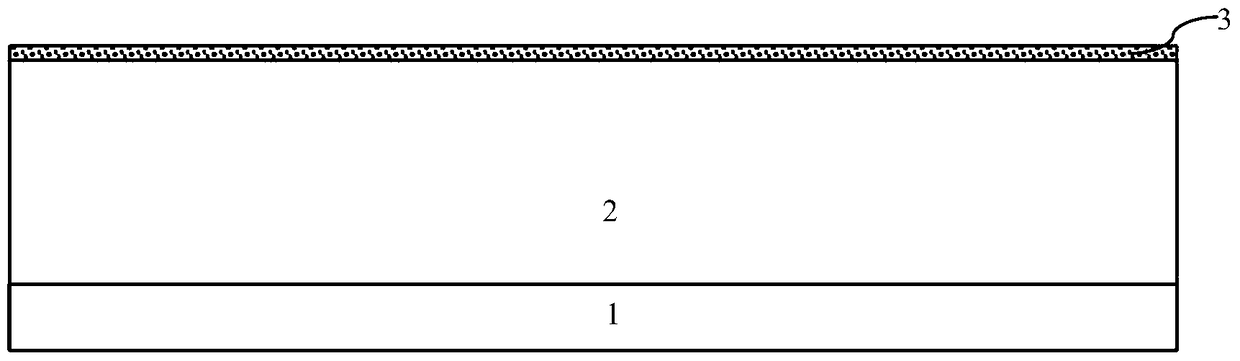

[0038] Step 1: Provide a semiconductor substrate such as a silicon substrate 101 , and an N-type epitaxial layer such as an N-type silicon epitaxial layer 102 is formed on the surface of the semiconductor substrate 101 .

[0039] Step 2: Forming a plurality of trenches in the N-type epitaxial layer 102 by photolithography. The hard mask layer 103 is used when etching the trench.

[0040] Step 3: filling the trench with a P-type epitaxial layer such as a P-type silicon epitaxial layer 104 during epitaxial growth, and the P-type epitaxial layer 104 will simultaneously extend to the surface of the N-type epit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com