Working platform with adjustable length for power field

A working platform and electric power technology, applied in the direction of manufacturing tools, overhead line/cable equipment, workshop equipment, etc., can solve the problems of high labor intensity and poor convenience for operators, and achieve the advantages of simplified and convenient operation steps, safe construction and avoiding sliding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

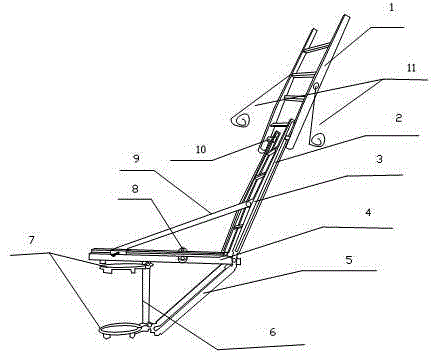

[0018] Such as figure 1 As shown, the present invention includes a first square ladder 1, a second square ladder 3, an insulating diagonal support rod 5, two hoops 7, a connecting rod 6, an insulating mounting platform 4 and an insulating diagonal stay rod 9. The second square One end of the ladder 3, the insulating installation platform 4 and the insulating diagonal support rod 5 is movably connected together, and the insulating installation platform 4 is located between the second square ladder 3 and the insulating diagonal support rod 5; The hoop 7 is also connected to the bottom of the insulating diagonal support rod 5 and the insulating installation platform 4 at both ends of the connecting rod 6; and can slide back and forth on the insulating installation platform 4; both sides of the second square ladder 3 are provided with chute 2, and two rollers 10 are arranged at the bottom of the first square ladder 1, and the two rollers 10 are respectively located on the first si...

Embodiment 2

[0021] In this embodiment, on the basis of Embodiment 1, the following technical enhancements are added: steel ropes 11 are respectively arranged on both sides of the first square ladder 1 . Both sides of the insulating mounting table 4 are respectively provided with sleeve holes 8 . When the first square ladder is lifted to the required height, pull the steel ropes located on both sides of the first square ladder to the sleeve holes to fix it, so as to increase the stability of the first square ladder, and the operator stands on the first square ladder It is safer and will not affect the sliding of the insulating diagonal stay rod on the insulating installation platform.

Embodiment 3

[0023] The preferred specific structure of this embodiment is as follows on the basis of the above-mentioned embodiments: bolts are also arranged between the sliding end of the insulating diagonal stay rod 9 and the insulating mounting platform. When the insulation-free diagonal stay rod slides, the position of the second square ladder is also fixed, and the operator can realize the operation by standing on the square ladder, making the construction safer.

[0024] The insulating diagonal support rod 5 can rotate around the common end of the insulating diagonal support rod 5 and the connecting rod 6 .

[0025] The insulating diagonal support bar 5, the connecting bar 6 and the insulating installation platform 4 form a triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com