Liquid-receiving unit and rotary electric machine

A technology for rotating electrical machines and liquid storage, which can be used in electromechanical devices, electrical components, electrical components, etc., and can solve problems such as insulation performance degradation and short-circuit accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

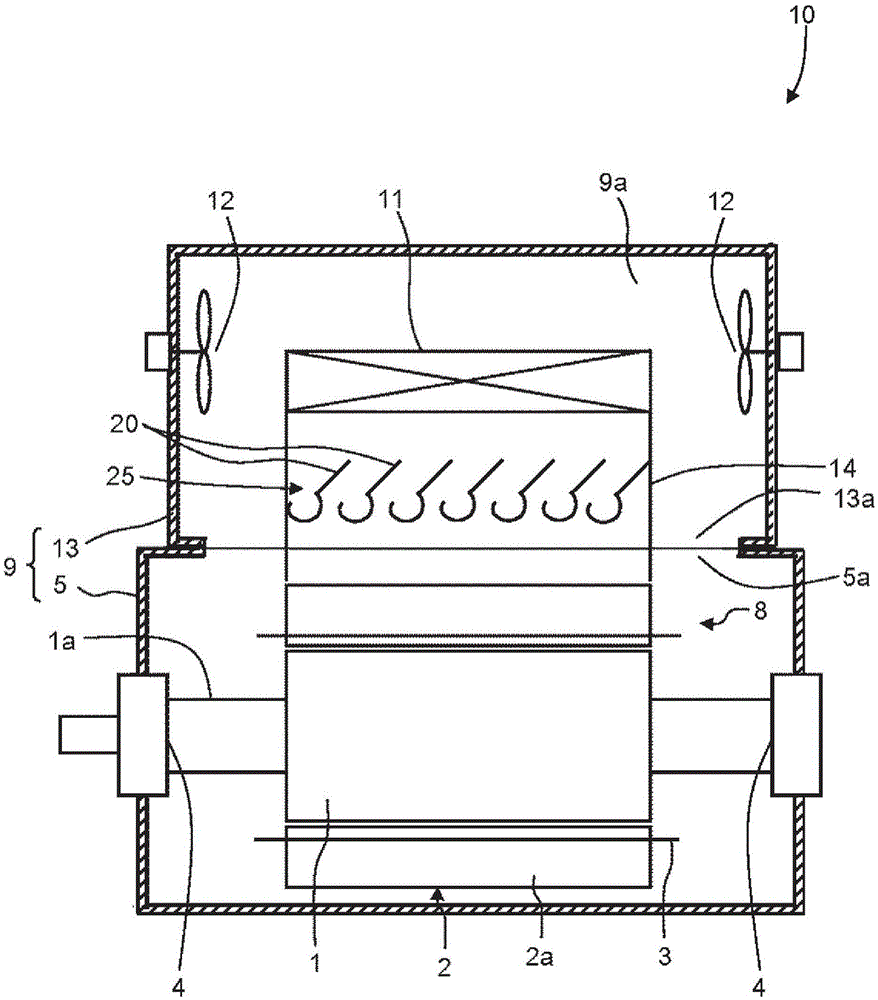

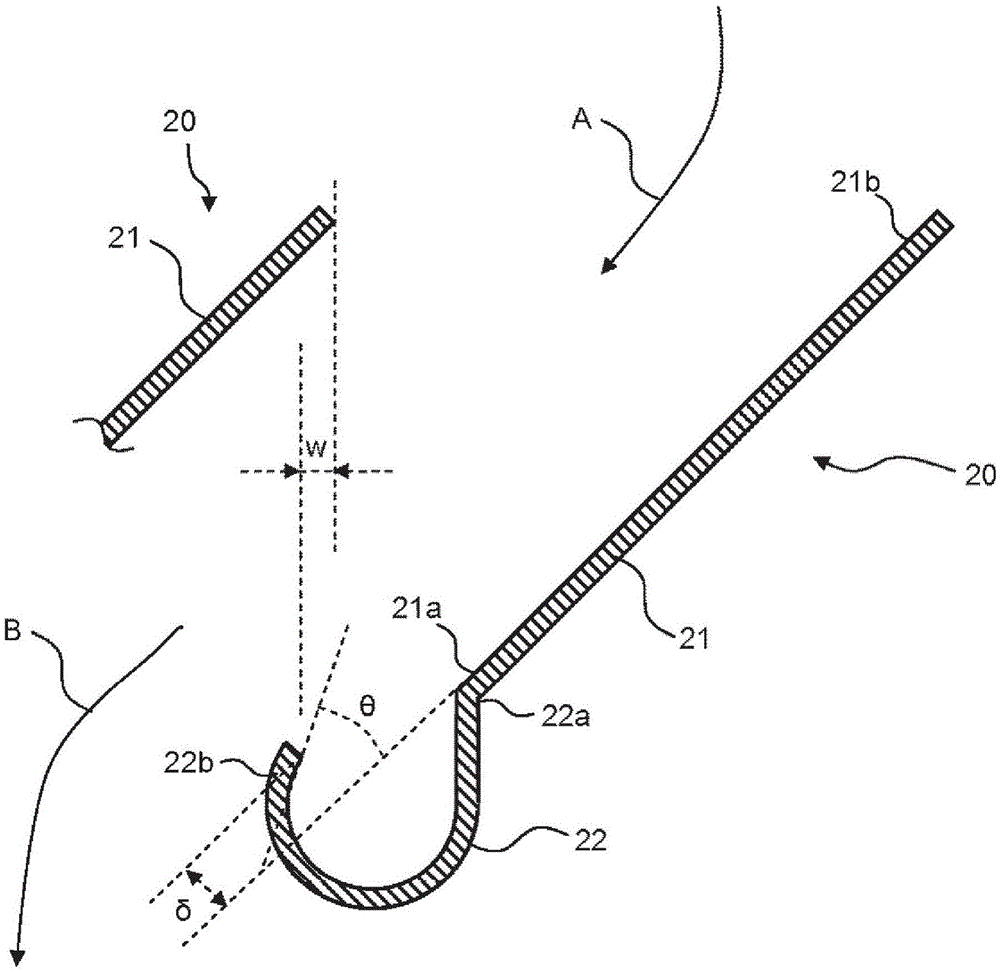

[0021] figure 1 It is a longitudinal sectional view showing the structure of the rotating electric machine according to the first embodiment. The rotary electric machine 10 has a rotor 1 and a stator 2 . A rotating electric machine main body 8 composed of a rotor 1 and a stator 2 is housed in a housing 5 . The rotor 1 is disposed radially around a shaft 1a extending on the axis, and rotates together with the rotation of the shaft 1a. The shaft 1a penetrates the housing 5 at both ends in the axial direction, and is rotatably supported by bearings 4 respectively fixed to both sides of the housing 5 . The stator 2 is disposed on the outer periphery of the rotor 1 at a distance from the rotor 1 in the radial direction. The stator 2 has a stator core 2a and a stator winding 3 wound on the stator core 2a.

[0022] The upper portion of the housing 5 is formed with a housing opening 5a. A cover portion 13 is attached to the upper portion of the housing 5 . A cover opening 13 a f...

no. 2 approach

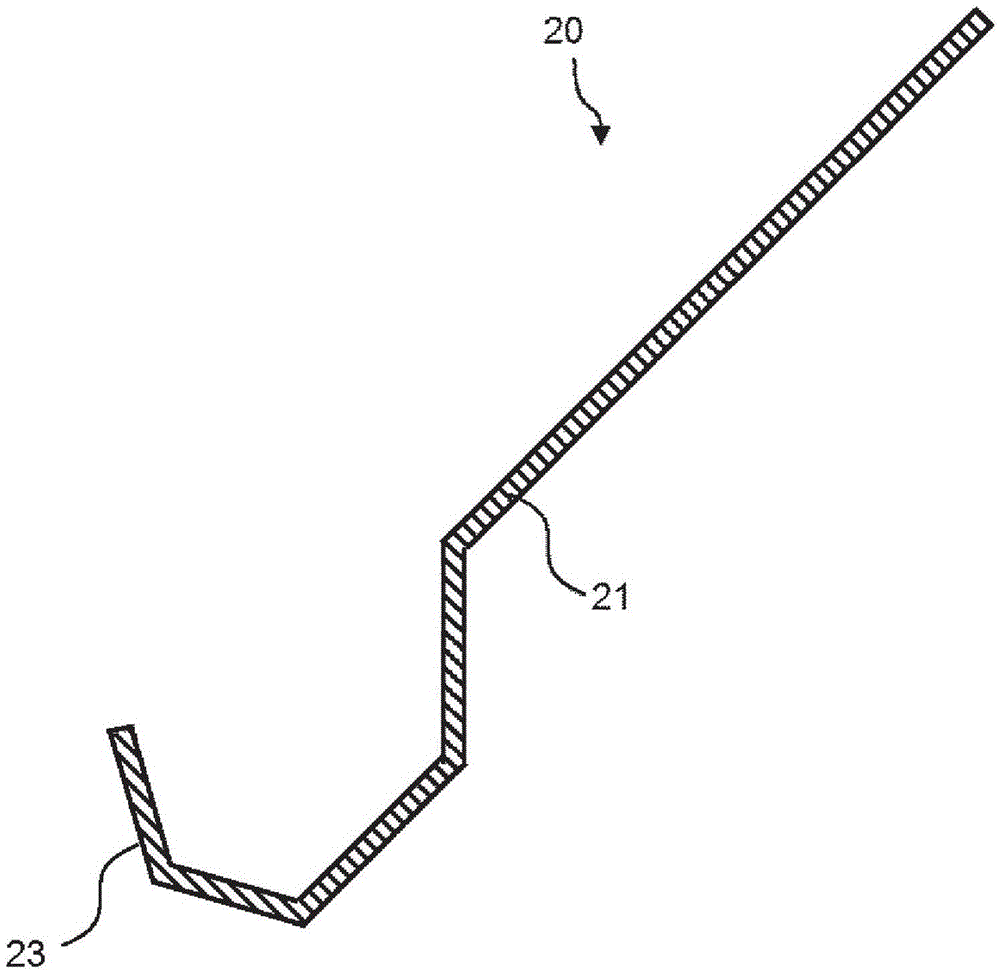

[0038] image 3 It is a transverse cross-sectional view showing a liquid reservoir of the rotating electric machine according to the second embodiment. This embodiment is a modification of the first embodiment. The liquid holding and transferring unit 23 according to the first embodiment is formed to have a rounded curved surface in a direction perpendicular to the longitudinal direction. On the other hand, the liquid holding and transferring portion 23 in the second embodiment is formed to have a plurality of planes connected to each other in a direction perpendicular to the longitudinal direction.

[0039] According to the present embodiment configured as described above, it is possible to reduce the burden of design and manufacture of the liquid reservoir 20 and reduce costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com