Treatment system for waste water from exhaust gas desulfurization in gas-electricity generating device

A waste water treatment system and waste gas desulfurization technology, which is applied in oxidation water/sewage treatment, flocculation/sedimentation water/sewage treatment, sedimentation tank, etc. The effect of cleanliness, space saving and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

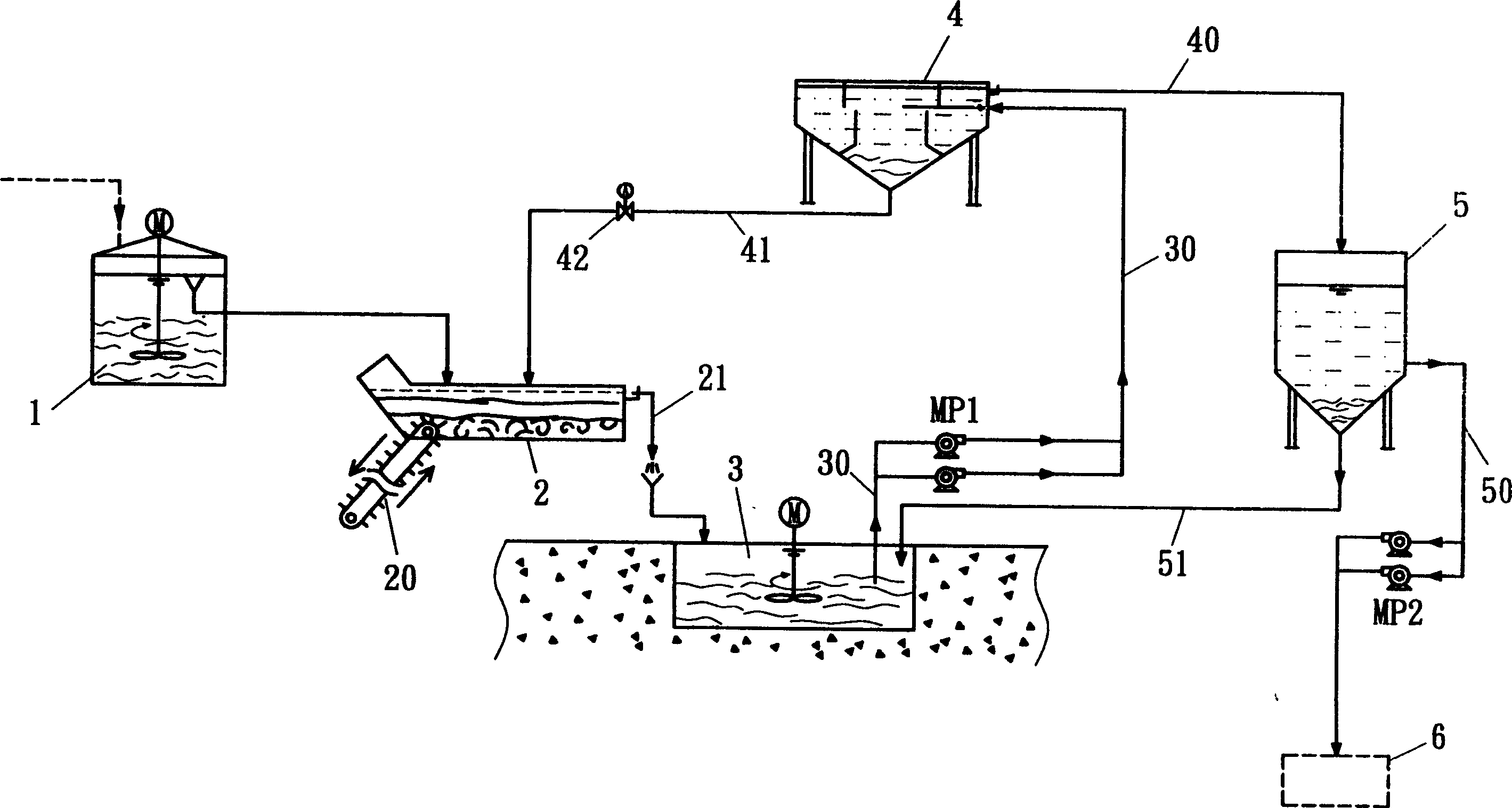

[0024] The composition, flow, functions and effects of the wastewater treatment system of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] Such as figure 1 As shown, the wastewater treatment system of the present invention comprises: oxidation tank 1, boiler water seal tank 2, bottom ash stirring tank 3, quick sedimentation tank 4, waste water tank 5, and its system arrangement, the method for processing are:

[0026] Oxidation tank 1: Receive the waste water containing magnesium sulfate or magnesium sulfite from steam-electric cogeneration desulfurization equipment. It has the function of aeration and can be stirred to make it oxidize, so that the waste water is magnesium sulfate (MgSO 4 ) solution state;

[0027] Boiler water seal tank 2: withstand the magnesium sulfate-containing wastewater from oxidation tank 1 to produce a preliminary precipitation effect, that is to say, the wastewater coagulates with the ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com