Connection structure of plastic pipe fitting and hula hoop using connection structure

A technology of plastic pipe fittings and connecting structures, which is applied to the connection of rods, connecting components, and moving accessories. It can solve the problems of high manual assembly costs, high production costs of pipe fittings, and low production efficiency. It achieves simple structure, high production efficiency, and The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A connection structure of a plastic pipe fitting of the present invention will be further described in detail below with reference to the accompanying drawings.

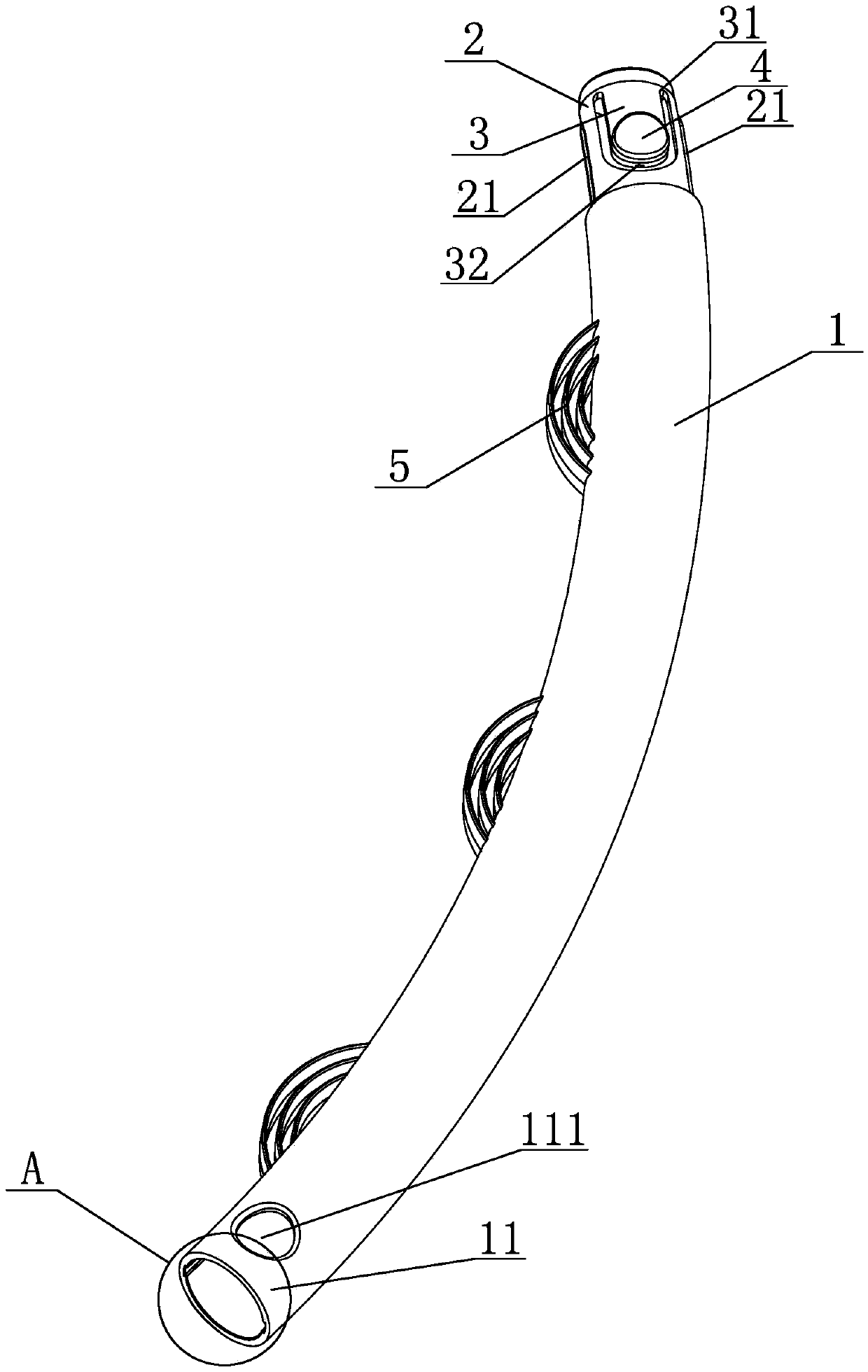

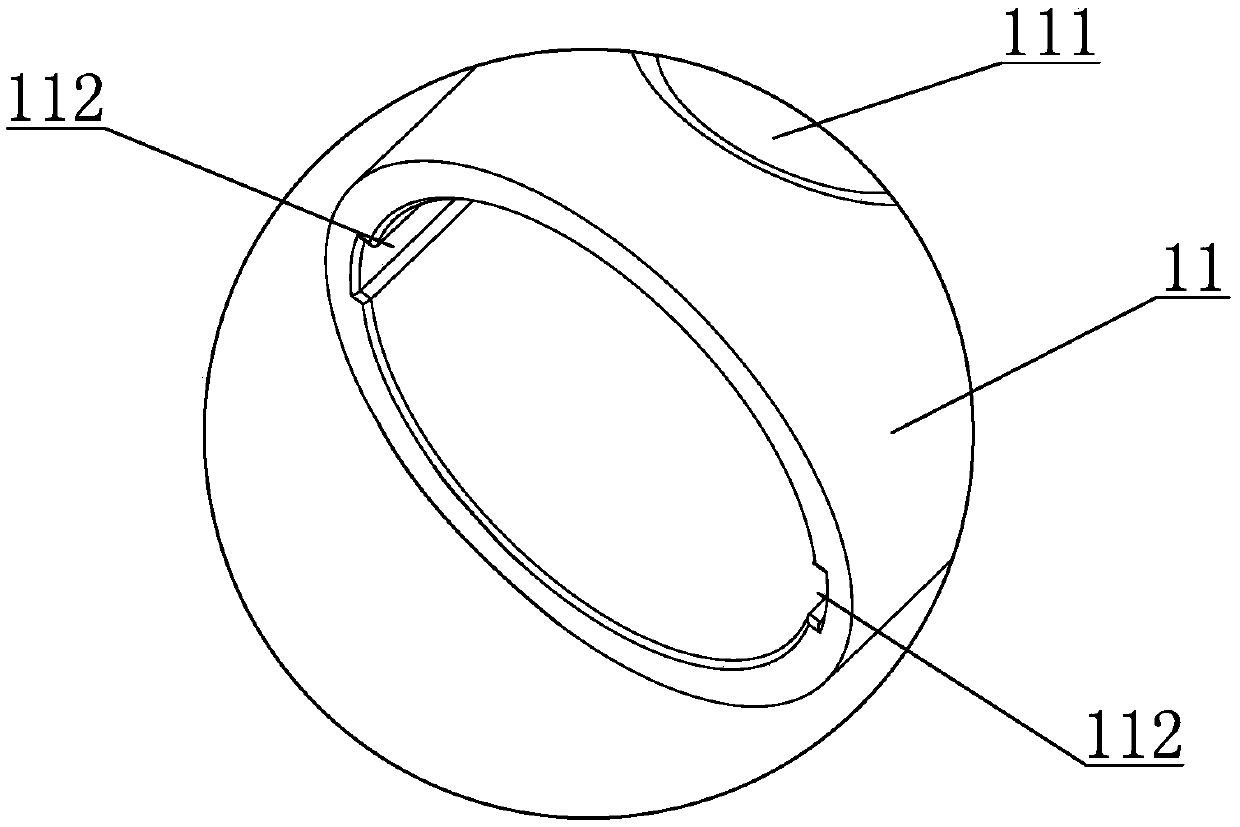

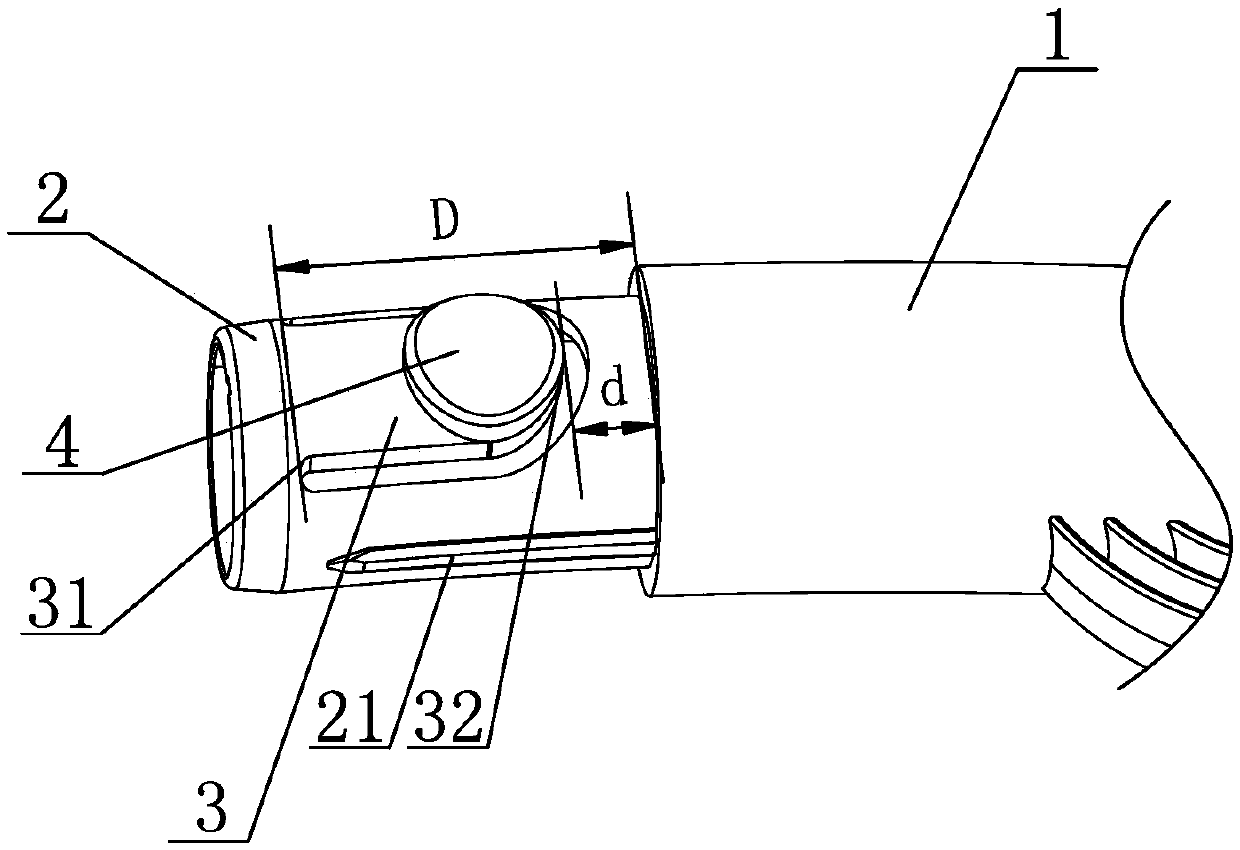

[0026] Such as Figure 1 to Figure 4 As shown, a connection structure of a plastic pipe fitting includes a hollow plastic pipe fitting body 1, the rear end of the plastic pipe fitting body 1 is a locking end 11, and a locking through hole 111 is provided on the locking end 11, and the plastic pipe fitting body 1 The front end is integrally extended with a hollow connecting pipe 2, the connecting pipe 2 is inserted into the locking end 11, and the connecting pipe 2 is integrally provided with a shrapnel 3, the shrapnel 3 includes a fixed end 31 and a free end 32, the fixed end 31 is fixed Set on the connecting pipe 2, the vertical distance d from the free end 32 to the front end surface of the plastic pipe fitting body 1 is smaller than the vertical distance D from the fixed end 31 to the front end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com