Mold processing device and processing system having same

A mold processing and processing system technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increased labor, inconvenient operation, time-consuming and laborious, etc. The effect of improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

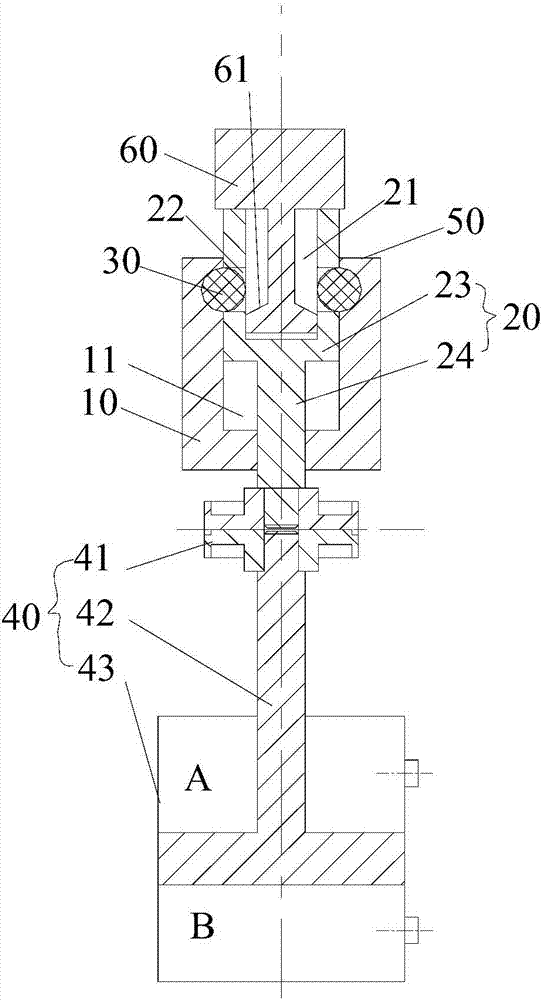

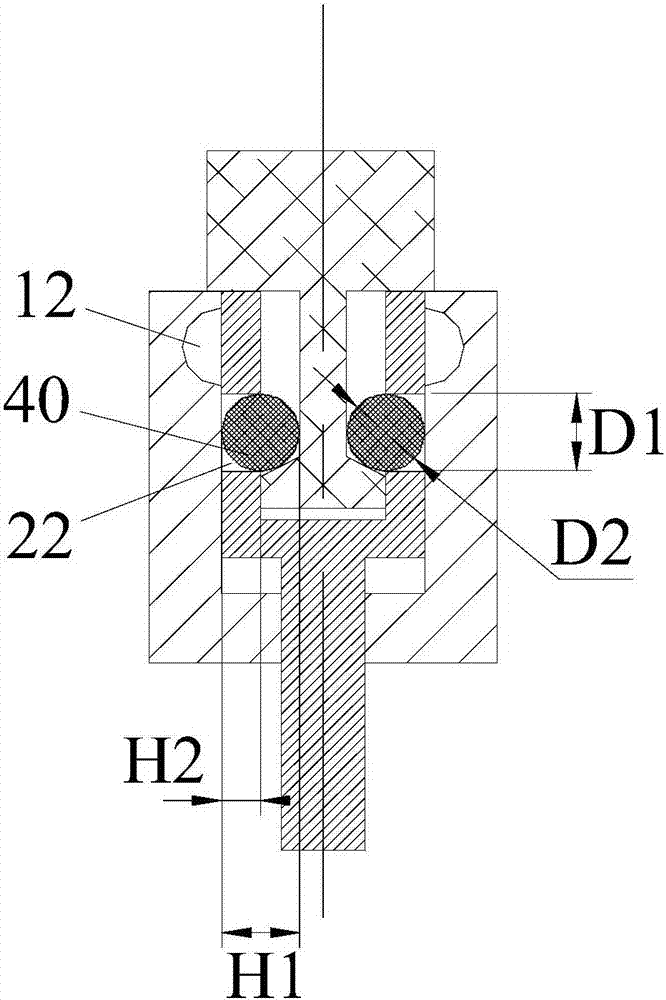

[0026] Such as figure 1 and figure 2 As shown, the present invention provides a mold processing device.

[0027] Specifically, the mold processing device is used for clamping and unclamping the mold, and the mold processing device includes a base part 10 , a supporting part 20 and a locking part 30 . The base part 10 has an accommodating cavity 11 , at least part of the supporting part 20 is located in the accommodating cavity 11 , and the at least part of the supporting part 20 is movably disposed in the accommodating cavity 11 along its own axial direction. The supporting part 20 has a mold receiving cavity 21 , and the mold is placed in the mold receiving cavity 21 . Further, the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com