Rubber plug perforating apparatus

A technology of punching device and rubber stopper, applied in metal processing and other directions, can solve the problems of unfixed rubber stopper and difficult punching process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

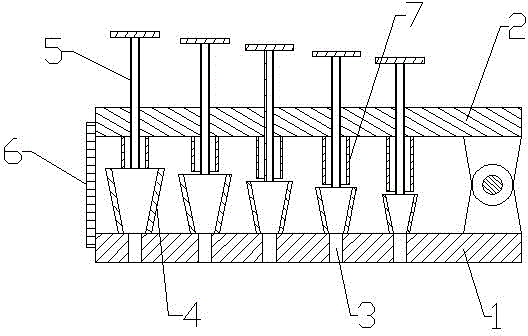

[0013] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of rubber plug punching device includes a base 1 and a pressure plate 2 hinged together at one end. The base 1 is provided with a number of inverted conical rubber plug cylinders 4 of different specifications, and the pressure plate 2 is provided with a number of different specifications. , the puncher 5 that can move up and down, the rubber plug tube 4 corresponds to the puncher 5 one by one, the puncher 5 is covered with a sleeve 7 that can fix the rubber plug, the upper end of the sleeve 7 is fixed on the inside of the pressure plate, relative to The sleeve 7 of the big rubber stopper is short and long relative to the sleeve 7 of the small rubber stopper, and the base 1 below each rubber stopper barrel 4 has a through hole 3 . A lock 6 is provided between the base 1 and the pressing plate 2 .

[0014] When in use, put the rubber plug into the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com