Non-pitwood withdrawing method for hydraulic supports during fully mechanized face withdrawing

A technology of hydraulic support and fully mechanized mining face, which is applied in the direction of mine roof support, pillar/support, mining equipment, etc., can solve the problems of low reliability of wooden point column support, non-recyclable wood, and great threat to construction safety, etc., and achieve recovery The effect of good withdrawal operation environment, good working environment and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

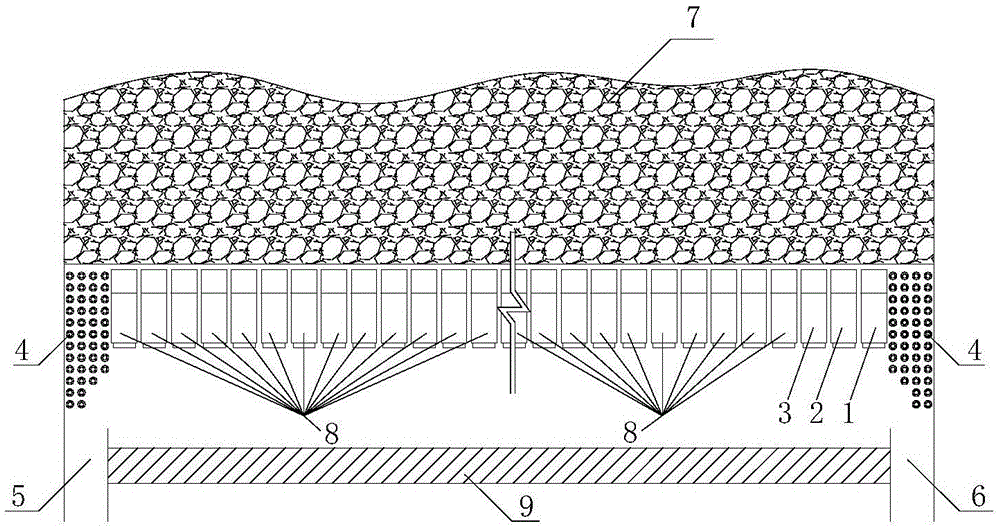

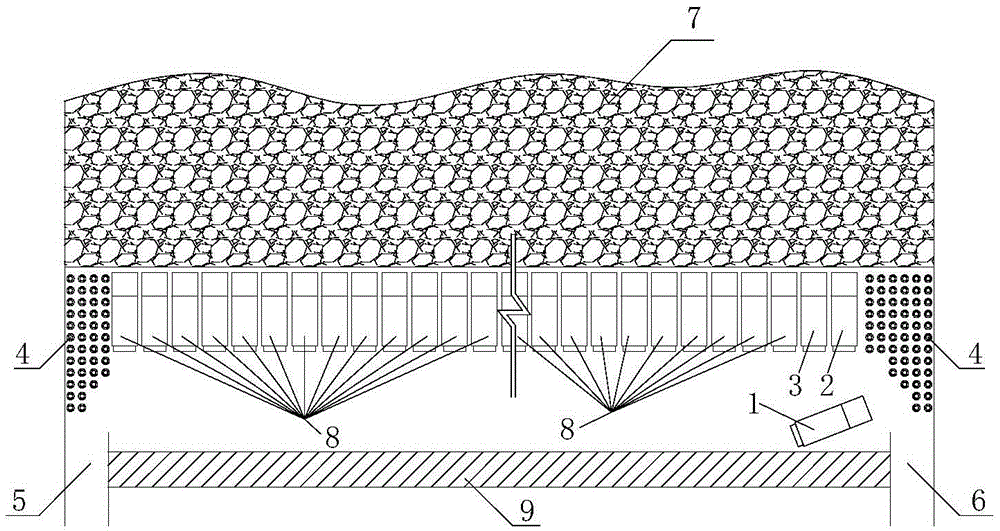

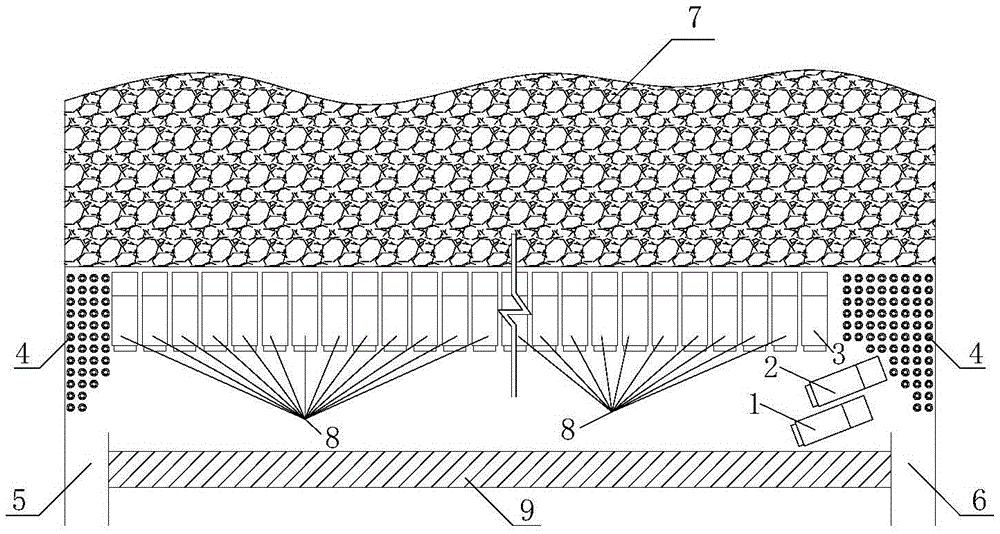

[0021] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~5 :

[0022] (1) When the fully mechanized mining face is closed, the plan view before the hydraulic support of the fully mechanized mining face is withdrawn is as follows: figure 1 shown.

[0023] (2) Pull out the first hydraulic support at the junction of the fully mechanized mining face and the section transportation level roadway according to the normal method of pulling out the frame, and adjust the hydraulic support to be basically consistent with the inclination direction of the cutting eye by using the slow winch traction, and lift it up The hydraulic support supports the roof, as the first mobile-support cover hydraulic support, such as figure 2 shown. Before withdrawing as the first mobile-support shielding hydraulic support, the front floor of the frame should be laid flat to prevent the hydraulic support from being skewed due to uneven bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com