Slide member rotation prevention device

A technology of sliding parts and sliding sleeves, which is applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problem that the guide hole and the guide pin cannot be closely matched, and achieve the effect of simple structure, reduced processing requirements, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

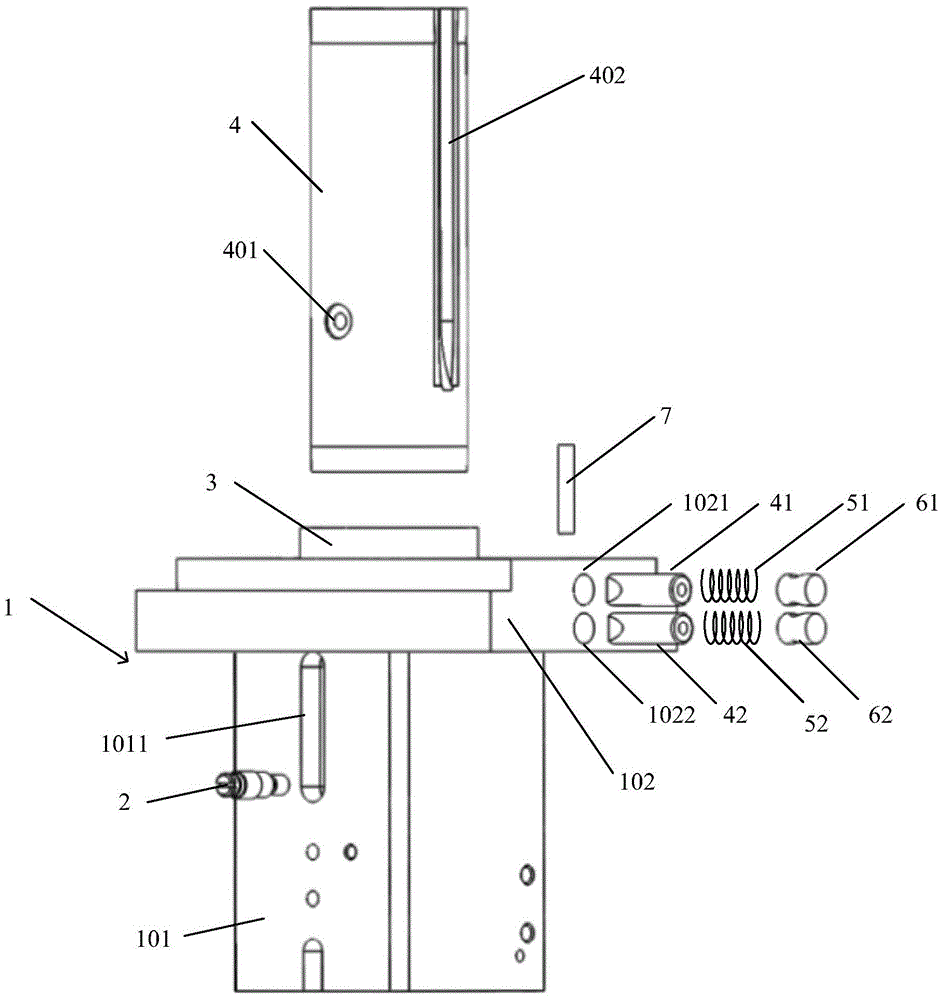

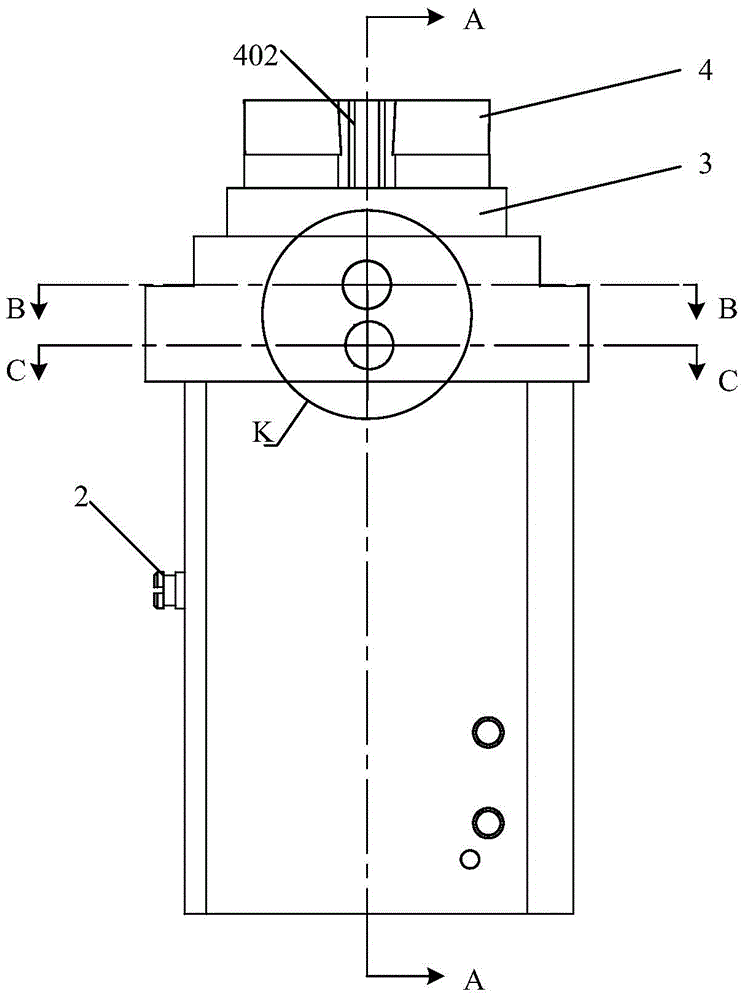

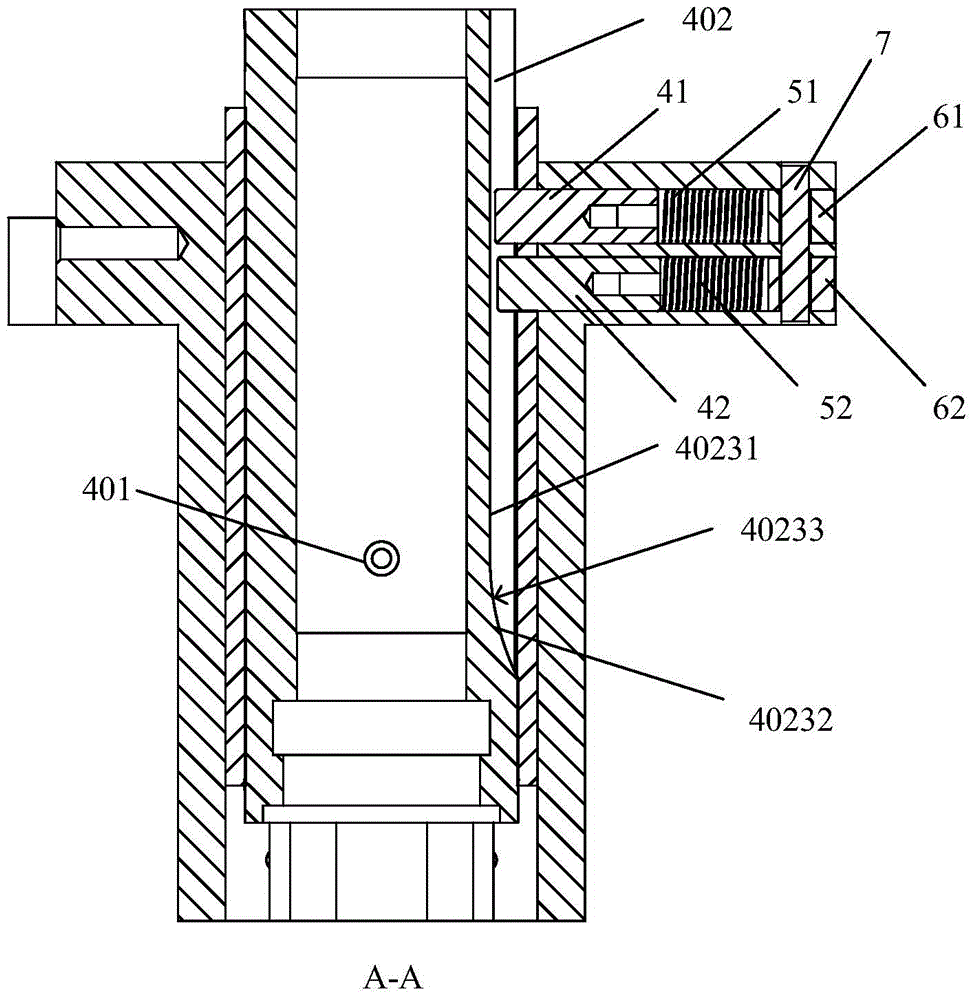

[0029] see figure 1 , a device for preventing a sliding member from rotating includes a main body 1 , a sliding sleeve and a limit screw 2 .

[0030] The sliding sleeve is a steel sleeve 3 shaped as a cylinder, the steel sleeve 3 is placed vertically, and one end of the steel sleeve 3 is fixed inside the main body 1 , and the other end of the steel sleeve 3 is higher than the main body 1 . The sliding part is a cylindrical copper sleeve 4, the copper sleeve 4 is inserted into the steel sleeve 3, and the copper sleeve 4 can slide vertically inside the steel sleeve 3, that is, the copper sleeve 4 4 to be able to slide up and down. A first side 101 of the main body 1 is provided with a waist hole 1011, the straight side of the waist hole 1011 is the same as the sliding direction of the copper sleeve 4 (that is, the straight side of the waist hole 1011 is vertical), and the limit screw 2 Through the waist hole 1011 is fixedly connected with a screw hole 401 formed on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com