A color steel plate composite air duct

A technology of composite air ducts and color steel plates, applied to pipes, pipe components, rigid pipes, etc., can solve the problems of complex manufacturing process, escape of sandwich insulation materials, and insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

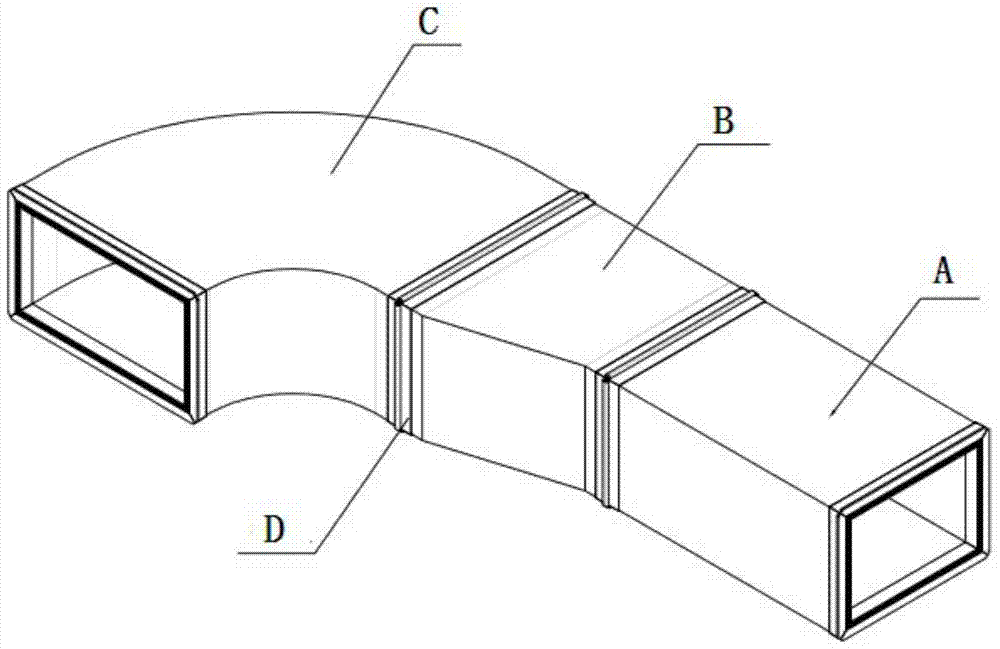

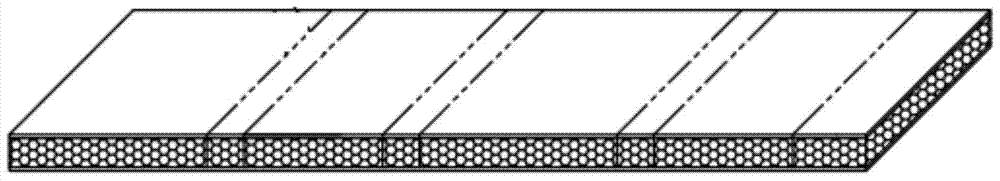

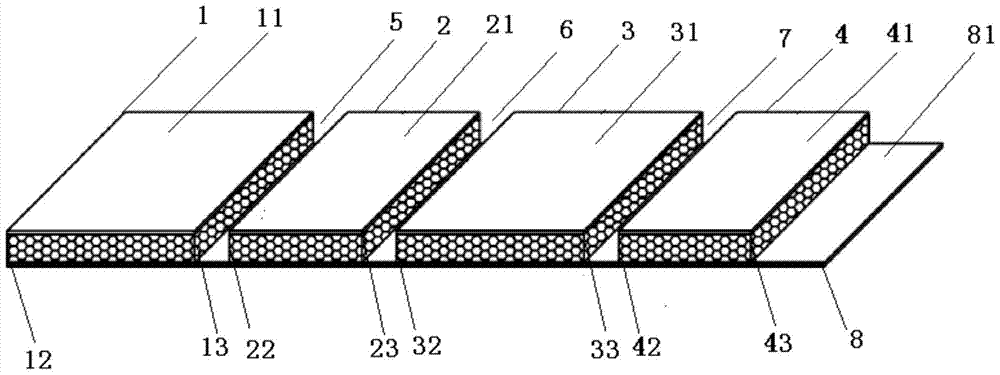

[0082] Such as Figure 1~22 As shown, the present invention provides a specific embodiment of a color-steel composite air duct. The color-steel composite air duct is composed of several air duct sections connected by a clip-type quick-installation connection device D, and the air duct section includes a straight pipe section A , variable-diameter pipe section B and elbow pipe section C, the clip-type quick-fit connection device D is composed of two aluminum alloy heat-insulating bridge breaker flanges D1 integrally connected by a C-shaped clip D2, wherein: two aluminum alloy spacers The connection between the flanges of the thermal break bridge is coated with a sealing strip; two adjacent straight pipe sections A can be fastened through the snap-type quick-fit connection device D, and two adjacent variable-diameter pipe sections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com