Testing method for uniformity of spherical lens material

A spherical lens and detection method technology, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve problems such as the inability to evaluate the uniformity of lens materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

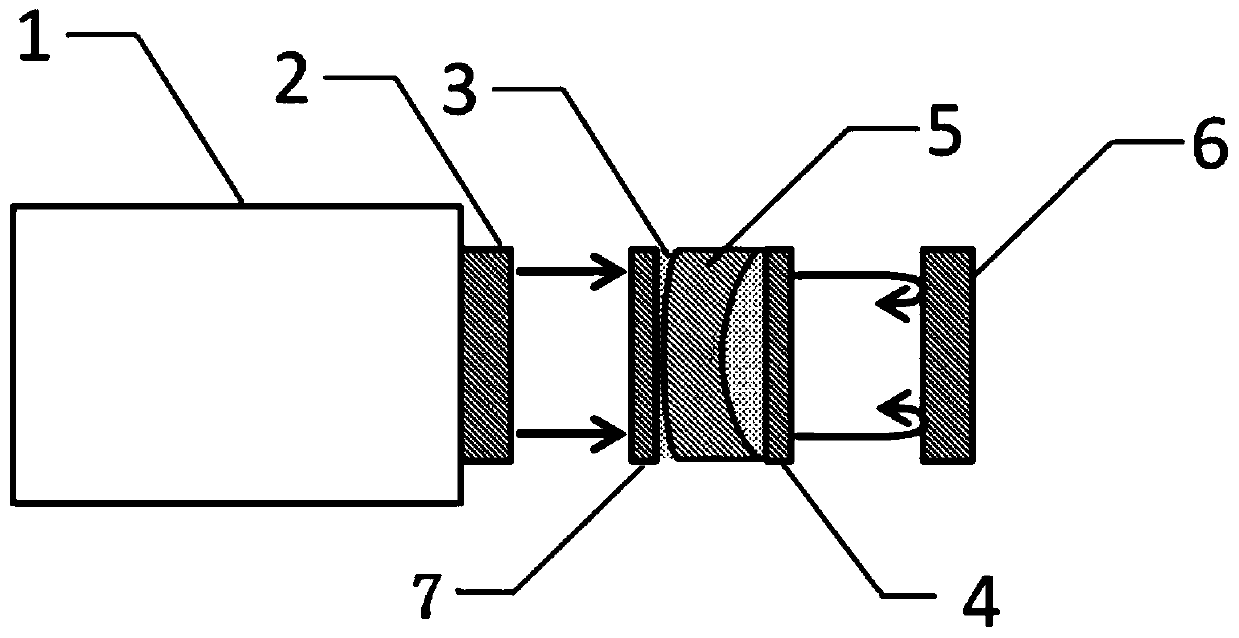

[0022] figure 1 It is a schematic diagram of the uniformity detection method of spherical lens materials, and the detection of uniformity of spherical lens materials by combining phase-shifting interferometry technology, refractive index matching liquid and mounting plate includes the following steps:

[0023] Step 1: Build a spherical lens material uniformity testing device, including an interferometer 1, a transmission plane etalon (TF) 2, a refractive index matching liquid 3, a mounting plate 4, an inspected lens 5, and a reflection plane etalon (RF) 6 , all components are placed coaxially. Immerse the tested lens 5 in the refractive index matching liquid 3, and use two sticking plates 4 to form a container for the refractive index matching liquid 3, wherein the refractive index of the refractive index matching liquid 3 at the working wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com