Transfer system and material-handling system and method using such transfer system

A technology of handling system and transmission system, which is applied in the field of transmission system, can solve problems such as the narrow point of the buffer system, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

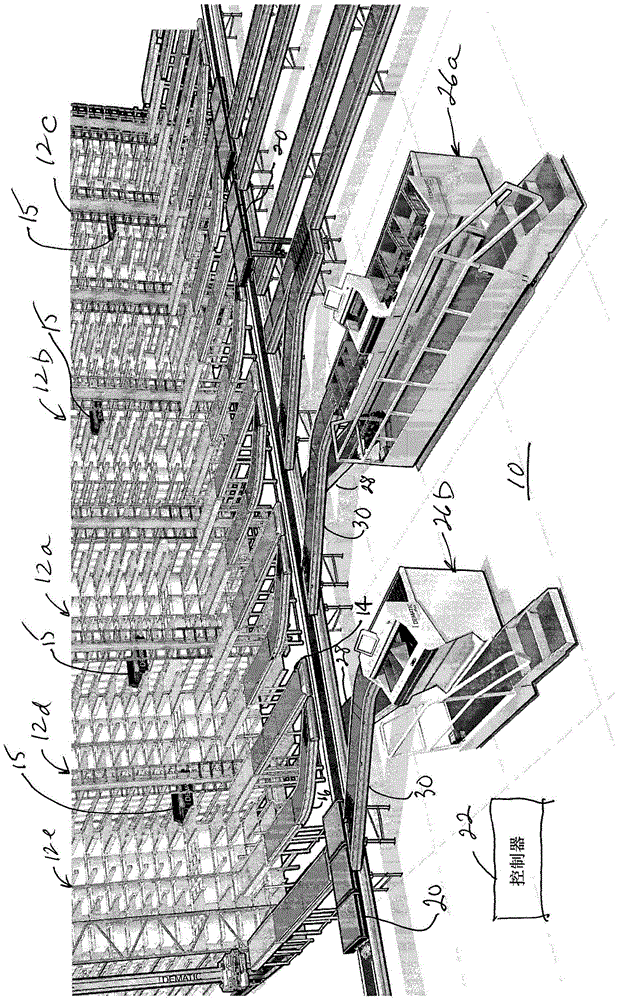

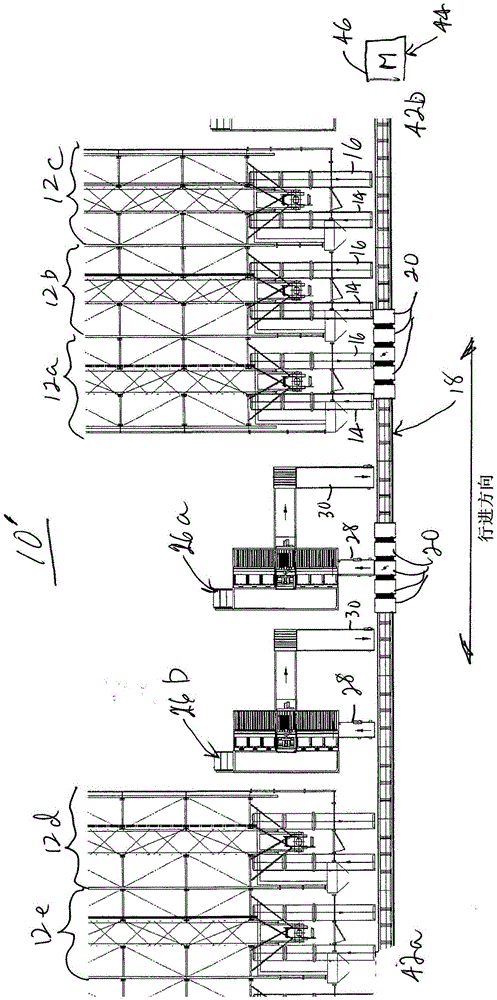

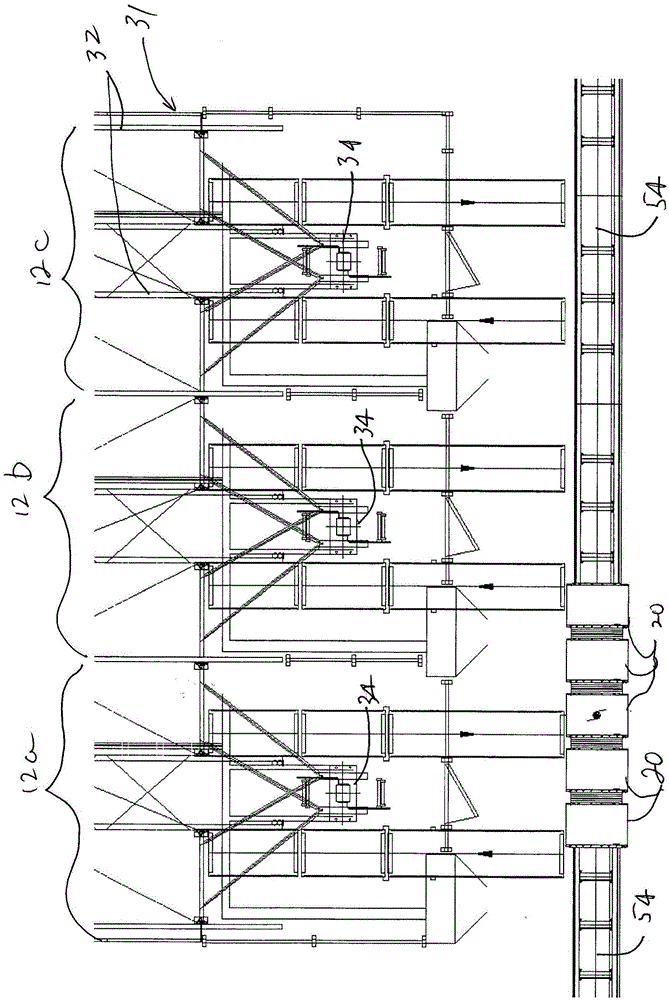

[0018] Referring now to the drawings and the illustrative embodiments described therein, a material handling system 10 includes a plurality of first processing stations 12 and second processing stations 26, the first processing stations 12 being referred to as stations 12a, 12b, 12c, 12d. …12n( figure 1 and figure 2 ), the second processing station 26 is referred to as station 26a, 26b...26n. Material handling system 10' is substantially the same as system 10, except that processing stations 12, 26 have a different physical layout than material handling system 10. Each processing station 12 has a first input 14 configured for receiving items and a first output 16 configured for unloading items from the respective processing station. For example, if the first processing station 12 is an item storage system, the first input 14 is used to supply items stored in the storage system and the first output 16 is used to unload items from the storage system.

[0019] The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com