Screening equipment based on vibration of electrically controlled mechanical structure

A technology of vibrating screening and mechanical structure, which is applied in the fields of filtering, solid materials, solid separation, etc. It can solve the problems of cumbersome procedures and low production efficiency, and achieve the effects of simplifying procedures, improving production efficiency, and precise measurement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

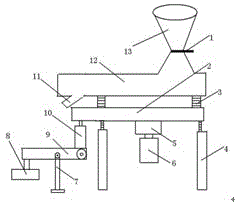

[0014] Such as figure 1 As shown, a screening device based on electrical control of mechanical structure vibration, its structure includes: feed valve 1, fine material collection plate 2, vibration spring 3, pillar 4, vibration driver 5, drive motor 6, lever support rod 7 , Electronic weighing device 8, lever 8, coupling 10, block material outlet 11, vibrating screen 12, feed hopper 13.

[0015] Such as figure 1 As shown, the lower left part of the vibrating screen 12 is provided with a block material outlet 11, the feed hopper 13 is installed on the upper right of the vibrating screen 12, and the feed valve 1 is installed between the feed hopper 13 and the vibrating screen 12 .

[0016] Such as figure 1 As shown, the vibrating screen 12 is connected with the fine material collecting plate 2 through the vibrating spring 3 and the fine material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com