An anti-blocking device and method suitable for the foam nozzle of the cutter head of the shield machine

A technology of shield machine and foam, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., and can solve the problems of high labor intensity, loss of protection, and danger for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

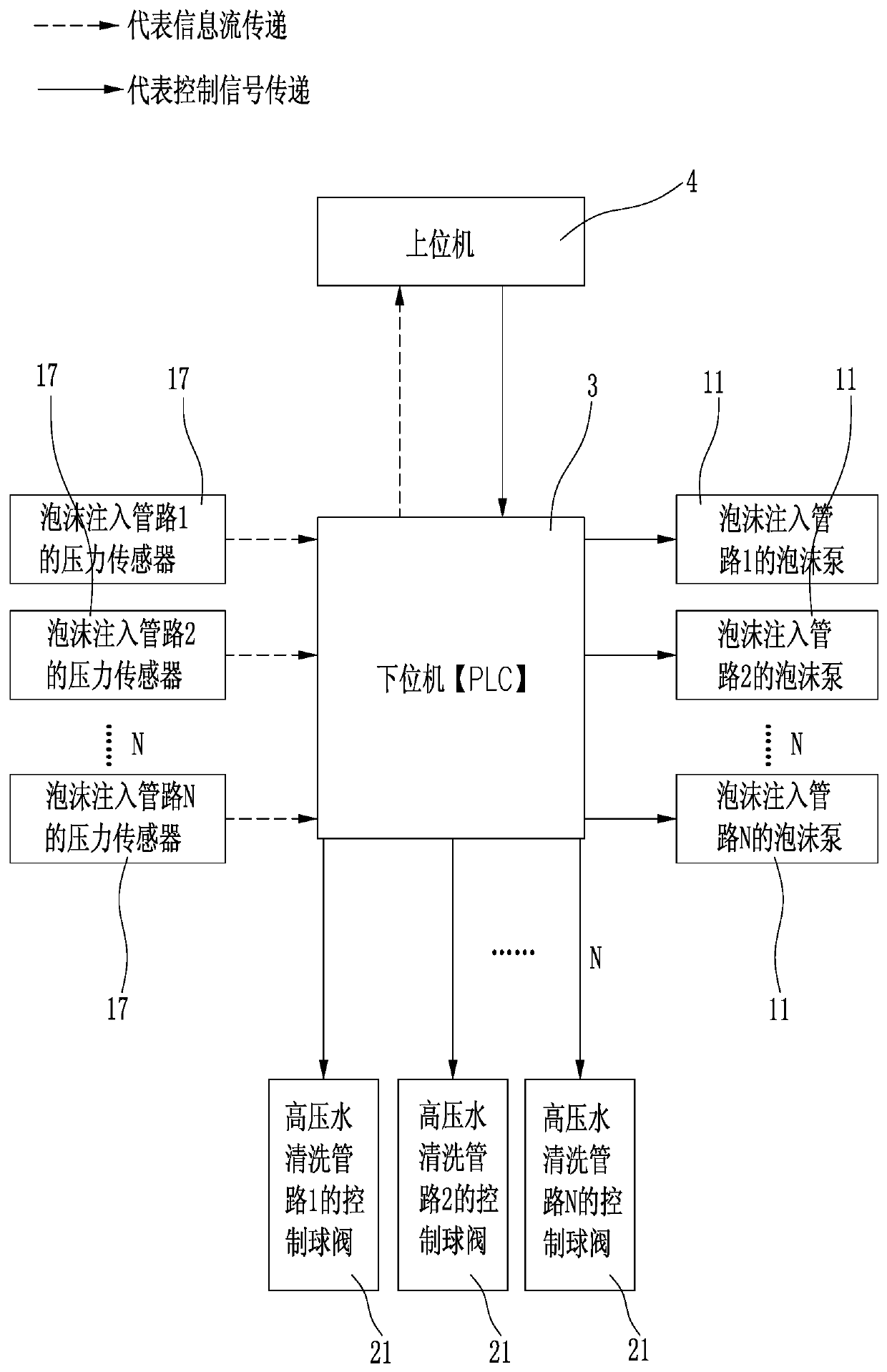

[0023] Such as figure 1 As shown, the present invention is an anti-blocking device suitable for the foam nozzle of the cutter head of the shield machine. The foam system of the shield machine includes a plurality of mutually independent foam injection pipelines 1, and the foam injection pipeline 1 is composed of Foam pump 11, pressure gauge 12, first one-way valve 13, flowmeter 14, foam generator 15, foam mirror 16, pressure sensor 17, ball valve 18 and second one-way valve 19 are formed in series successively, simultaneously in foam pump 11 is also connected in parallel with a safety valve 111 to ensure the normal operation of the foam pump 11. A foam spout is provided at the end of the foam injection pipeline 1, and the foam spout is arranged in the cutter head device (not shown); The first one-way valve 13 and the second one-way valve 19 on the pipeline 1 are separately connected to the high-pressure water cleaning pipeline 2, and each high-pressure water cleaning pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com