Adjustable pipeline supporting part

A technology of pipeline support and support column, applied in the direction of pipeline support, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem of long time required for positioning, affecting pipeline installation, etc., to achieve a large adjustment margin and ensure installation. quality, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

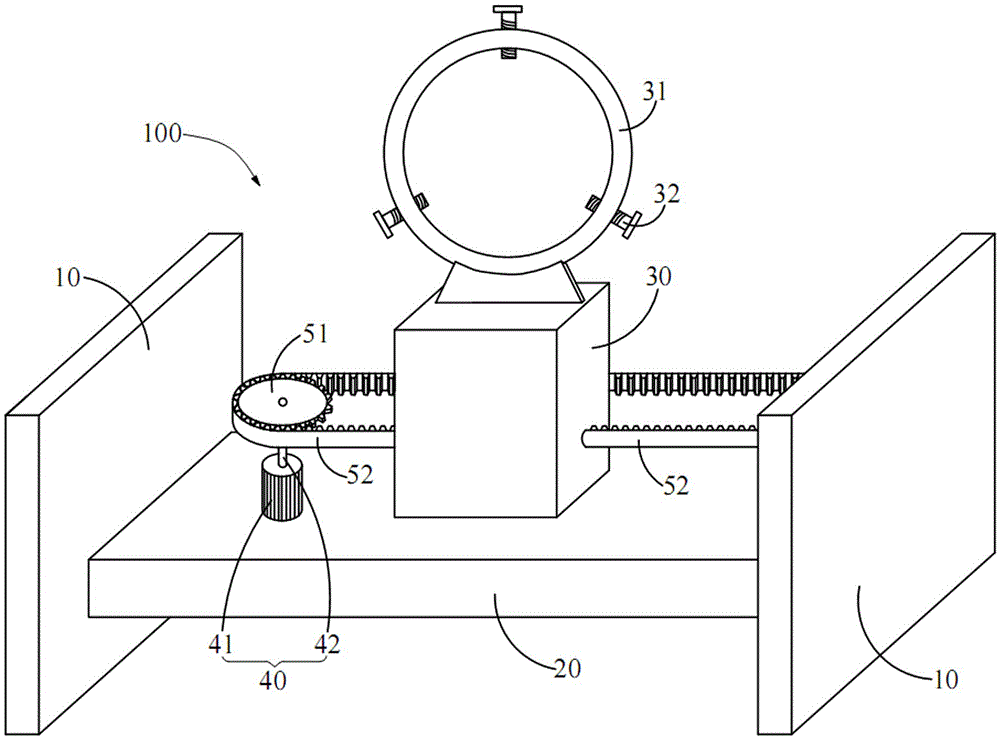

[0017] see figure 1 , the pipe support 100 shown in the preferred embodiment of the present invention includes two columns 10, a horizontal plate 20 disposed between the two columns 10, a support column 30, a motor 40 and a moving assembly.

[0018] The two uprights 10 are vertical relative to the ground, and the two uprights 10 are arranged at intervals, and the distance between the two uprights 10 can be specifically set as required.

[0019] The horizontal board 20 is installed between the two columns 10 relatively vertically, and the horizontal board 20 is parallel to the ground.

[0020] The support column 30 is relatively slidably mounted on the horizontal plate 20 . The end of the support column 30 away from the horizontal plate 20 is fixedly connected to the fixed ring 31 for the pipeline to pass through. Specifically, the fixed ring 31 can be fixedly connected to the support column 30 directly, or through a The connecting block (not shown in the figure) is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com